Automated Guide Rail Adjustment

Changeovers At The Touch of a Button increase efficiency in changeovers and provide transparency of Overall Equipment Efficiency at your fingertips.

Automated Guide Rail Adjustment is the ultimate Guide Rail Adjustment feature, freeing up operators time for other production areas. In a time-sensitive world, Customers routinely stress the need for greater line efficiency, reduced changeover time, less downtime and elimination of operator set up errors that will reduce operator set up adjustments while running production.

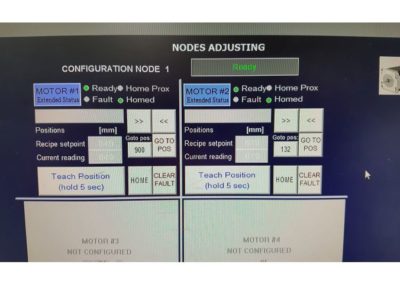

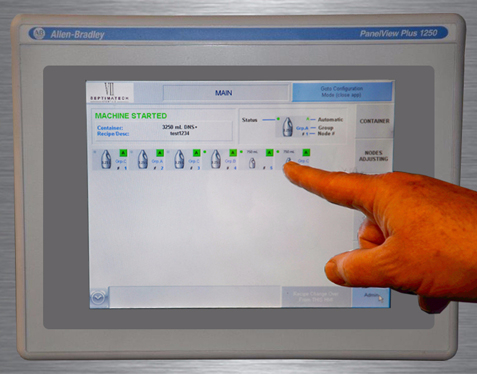

The use of a Human-Machine Interface presents instant information to an operator about the state of their packaging line during setup and operation. The Automated Guide Rail Adjustment System has user friendly product set up and product recipe selection through a Human Machine Interface when introducing new containers. Automated Guide Rail Systems can be stand-alone or directly interface into existing electrical control panels.

The distributed controls architecture and optional Pack/ML interface allows the automation of changeovers on an entire line, or just a small difficult-to-access section. Larger systems can utilize a combination of control nodes and power distribution nodes to minimize cabling and installation costs. The same modules can also control automatic adjustment of the Septimatech Multi-Lane Adjust® (MLA) system, providing end-to-end integration of your product changeover.

Septimatech Automated Guide Rail Adjustment systems are designed to complement the mechanical capabilities of Unison® or Easy Adjust® adjustable guide rails. Each Automated Guide Rail Adjustment System is configured to best suit your line layout and operating requirements, with user-friendly product set-up and recipe selection through a Human Machine Interface touchscreen.

Comprehensive Features:

- Quick disconnect cabling

- Easy to integrate into or retrofit an existing Unison® or Easy Adjust Rails® mechanical system

- Integrated controller and Human Machine Interface

- Dual channel safety interface

- Distributed controls architecture

- Compliant to operate in a wash-down environment NEMA 4X or IP65

- Supervisory communications gateway options

- Torque of 3Nm minimum to 6Nm for your specific application. Speeds of 50 RPM or less

- Automation requirements accommodate any specific requirements for sensing, homing, power down/up, production interference

- Integrates into existing line control and Human Machine Interface system or supplied as stand alone system

- Multiple controls platforms and motor options

- CE compliant

Automated Guide Rail Adjustment Resources

Unison® Automation

A Customer with a non-adjustable guide rail system wanted to fully automate changeover of its guide rails to reduce downtime, eliminate set up variables created by different operators, and improve safety. They also wanted to improve throughput and eliminate container scuffling, shingling, and tipping which slowed production and caused product damage.