Find Septimatech at Booth C-4036!

The annual Pack Expo is coming up on September 25-27, 2017 at the Las Vegas Convention Center, Las Vegas, Nevada.

Don’t miss your chance to meet over 2,000 top industry suppliers, network with over 30,000 other attendees, and attend free educational presentations. It’s a great opportunity for packaging professionals to see new technologies in action.

Visit Septimatech at our booth C-4036 to see our featured solutions, including:

Line Adjustment Solutions

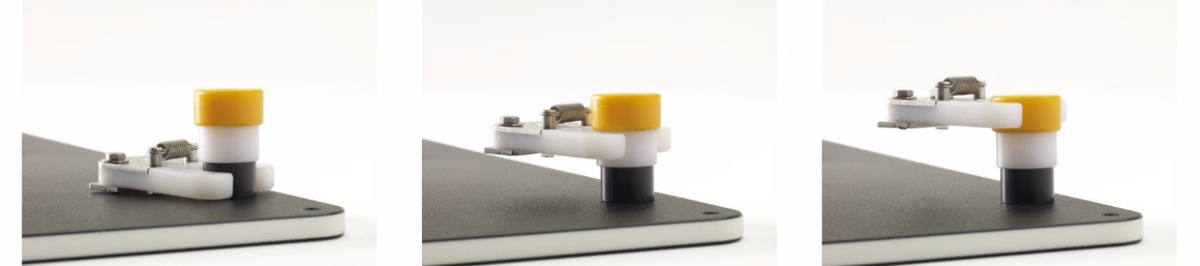

NEW! Unison® QT – Quick Turn Adjustable Guide Rail and Product Handling Control System

Unison® QT helps customers reduce changeover time from hours to seconds with accurate, repeatable, fast adjustment times.

Customers in every segment of the packaging industry can benefit from this system. It takes seconds to incrementally adjust guide rail width by 6.25 inches (160mm) with one turn of hand wheel. With just a quick turn of the adjustment handle, operators can uniformly set the correct Guide Rail position and lock it in place. The Unison® QT’s quick turn handle eliminates the need for individual Guide Rail adjustment, tweaking, or fine-tuning the changeover setup.

Each adjuster can be customized on-site to suit exact package sizes, giving optimal line flexibility to add or remove package sizes in the future.

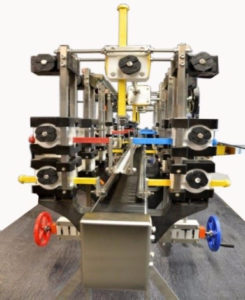

Unison® Automated Guide Rail System

Unison® Automated Guide Rail System

Unison® Automation is the ultimate Guide Rail Adjustment feature, freeing up operators and their time for other production areas. As well as improving line efficiency and reducing changeover time, this system reduces line downtime and eliminates the need for operator tweaking or adjustment during setup and production.

The human-machine interface provides operators with instant information about the state of their packaging line during changeover and run time. Through the easy to use Unison® touchscreen, operators can perform key functions including automated changeovers, manual jogging, recipe management and teaching, maintenance, and diagnostics.

Unison® Corners

Unison® Corners

Unison® Corners allows customers to quickly and easily adjust Guide Rails through corners, cross-overs, and s-curves while maintaining exact clearances and precise tolerances. It prevents container shingling and line stoppages due to jams and fallen bottles.

Every Unison® corner and curve improves and increases production uptime, efficiency through container handling control, and performance.

Unison® VH – Vertical and Horizontal Adjustment

Unison® VH – Vertical and Horizontal Adjustment

Customers in every segment of the packaging industry will benefit from Unison® VH’s ability to adjust an upper Guide Rail vertically to any height, allowing the Guide Rail to be positioned in exactly the right location on the container. Combined with the independent horizontal adjustment, this feature allows for precise configuration relative to container profile.

This Guide Rail ensures optimum control for a wide variety of challenging container geometry shapes and sizes prone to shingling, popping up, or tipping. Customers will no longer require dedicated packaging lines with complex rail systems to run a range of short, tall, narrow, or wide container profiles.

Machine Changeover Solutions

Anti-Torque Star

Anti-Torque Star

Our Anti-Torque Star was designed to control and cap a non-rigid bleach container with a complex geometric shape. It provided the stability and superior anti-torque capability needed to properly cap the product.

Spotting Star

Spotting Star

The Spotting Star was designed to ensure containers with an offset neck and handle would maintain proper orientation during filling. This dynamic spotting mechanism was mounted to the infeed star that worked with rollers in the pockets to rotate the containers and lock them in place once proper orientation for filling was achieved, virtually eliminating jams and miss-fills.

Urethane Star

Urethane Star

This star design with a urethane contact surface doesn’t leave sharp burrs or large deformations when exposed to broken glass, like UHMW, Nylon, or traditional plastic materials do.

This product significantly reduces noise during glass product handling and offers better resistance to wear compared to plastic guides.

Removable Pocket Star

Removable Pocket Star

Created as a robust, cost-effective solution to replace existing expensive crowner star assemblies, the Removable Pocket Star features a water damage resistant stainless steel skeleton with durable inserts that are easily replaced in minutes when required.

Wear-Strip Guides

Wear-Strip Guides

Wear-Strip Guides are ideal for customers experiencing label scuffing, excessive wear, or high maintenance costs. Septimatech designed a series of removable and replaceable wear-strips of different materials to fit various guides, which can easily be replaced when worn down instead of replacing the entire assembly.

These strips increase lifespan of guides, while also reducing the likelihood of damage to sensitive labels or containers due to friction.

Universal Gripper

The Universal Gripper is a versatile filler neck-handling solution designed for customers handling large profile containers in the edible oil or industrial oil industries. This product holds and orients a range of neck sizes without needing to change or add components, resulting in faster changeovers, reduced downtime, and quicker setup.

Adjustable Positioner

Adjustable Positioner

Customers from the household and personal care industries can reduce changeover time and the number of change parts for their filler with the Adjustable Positioner.

This product can be accurately and consistently set for different-sized containers; it is easily adjustable at four critical points to allow effective handling of large and small containers.

Feed Screws

Feed Screws

Our Feed Screws improve container control as the container enters the Feed Screw at the infeed, and as the container accelerates to the required discharge pitch to transfer smoothly into the machine star wheels.

Achieve flawless container transfers without scuffing, damage, marking, or spillage thanks to these products’ smooth surface finish and pocket-to-pocket accuracy.

Feed Screw Drive Systems

Septimatech’s Feed Screw Drive Systems are custom-engineered and manufactured to achieve the results you need in container handling. Whether your application requires single, dual, synchro, or infeed control, we can develop a creative Feed Screw Drive System for your specific application that makes difficult-to-control containers a thing of the past.

Smart Storage Systems

Smart Storage Systems

Our rugged and robust carts are designed to allow for maximum parts storage, organization, cleaning capabilities, ease of removal, and transportation of parts to the packaging line for improved operator productivity and floor space consideration.

The Smart Storage System also features built-in considerations for ergonomics, health, and safety.

We look forward to seeing you at Pack Expo 2017 in Las Vegas!

Septimatech is a leading worldwide provider of packaging machine and line productivity solutions, including Rapid Change Guide Rail Systems, Change Parts, Feed Screw Drive Systems, and more. Contact us today!

You may also be interested in:

- 7 Tips for Keeping Your Packaging Line Running at Peak Performance

- Introducing Our NEW Unison® QT Quick Turn Adjustable Guide Rail and Product Handling Control System

- See Our Unison® Automated Guide Rail System for the First Time at Pack Expo 2017!