We recently announced our newest product, the next generation of our Unison® Automated Guide Rail System, and we’re excited to share how it can help streamline your production process. The system made its debut at this year’s Pack Expo Las Vegas, where attendees experienced advanced technology firsthand.

We recently announced our newest product, the next generation of our Unison® Automated Guide Rail System, and we’re excited to share how it can help streamline your production process. The system made its debut at this year’s Pack Expo Las Vegas, where attendees experienced advanced technology firsthand.

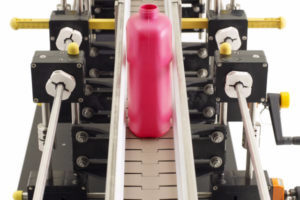

One Operator can automatically adjust guide rails, reduce non-productive changeover time, eliminate unnecessary tweaking, improve container handling performance and add newly introduced containers at the touch of a button quickly and efficiently. The Unison® Automated Guide Rail solution enables fast and repeatable changeovers for increased production efficiency—saving you time and money.

The Unison® Automated Guiderail System is the most efficient way to keep production on track, achieve reliable, repeatable, fast guide rail changeovers every time.

Features of the Unison® Automated Guide Rail System:

- Proven Solution: The system is designed using proven PLC and integrated drive platforms, deployed across a variety of industry segments having difficult-to-access elevated lines or challenging line configurations. Unison® Automated Systems can be installed on the entire production line or in specific areas where controlled container handling is needed.

- Reduced Changeover Time: If your line has conventional non-quick change guide rails, envision changeovers reduced from hours to minutes with the Unison® Adjustable Guide Rail System. Need to reduce that further, then apply automation to the Unison® System and achieve guide rail changeovers in seconds. Changeovers are completed by a single operator using an HMI screen, eliminating the need for specialized skills. Quicker changeovers mean less downtime and higher efficiency.

- Scalable and Customized to Your Needs: The Unison® Automated Guiderail System is scalable to meet the most demanding plant requirements. It’s easy to add future containers and maintain recipes. Customized images for recipe within the HMI, guaranteeing accuracy.

- Safety: Safety is the number one priority on the plant floor. The Unison® Automated Guiderail System is equipped with integrated safety features and is designed to CSA, UL, and CE standards.

- Easily Integrated: This system is easy to install to both new and existing lines. A standalone system includes a dedicated controller and HMI, providing operators with one-touch control guide rail adjustment during changeovers.

Designed to industry standard, Packaging Machine Language (PackML), coupled with an Ethernet gateway compatible with a variety of communications protocols, the system can be installed as a standalone solution or integrated to the line PLC with supplied software.

Automation is the future of the packaging industry— automate tasks to maximize labour talent.

Septimatech is a leading worldwide provider of packaging machine and line productivity solutions, including Rapid Change Guide Rail Systems, Change Parts, Feed Screw Drive Systems, and more. Contact us today!

You may also be interested in: