Septimatech Features New Packaging Line Efficiency and Productivity Solutions at Pack Expo Las Vegas 2019.

To see Septimatech’s solutions in action, Visit Booth C-3936, September 23-25 at the Las Vegas Convention Center.

Exhibiting for the First Time at Pack Expo Las Vegas

- Easy Adjust Rails® deliver fast, repeatable guide rail adjustment and changeover, without pneumatics or other high maintenance components.

- Multi-Lane Guide Rail Adjustment System eliminates change parts, lane spacers and heavy lifting equipment for quick, simple adjustment of multiple packaging lanes.

- In addition Septimatech also will exhibit its Rapid eXchange No Tool (RXNT®) change parts, Smart Storage Systems, Feed Screws and Feed Screw Drive Systems.

Easy Adjust Rails® |

|

|

Easy Adjust Rails® deliver fast, repeatable guide rail adjustment and changeover, without pneumatics or other high maintenance components. Increased efficiency, reduced labor and maintenance, and improved product handling combine to provide quick return on investment and outstanding total cost of ownership. Septimatech’s Easy Adjust Rails® easily retrofit to existing or new conveyor systems. Easy Adjust Rails® provide one-time calibration with no springs, seals or air pressure to maintain. Guide rail changes which typically take hours are reduced to minutes. All adjustments are accurate and repeatable for consistent performance and container control in every change. |

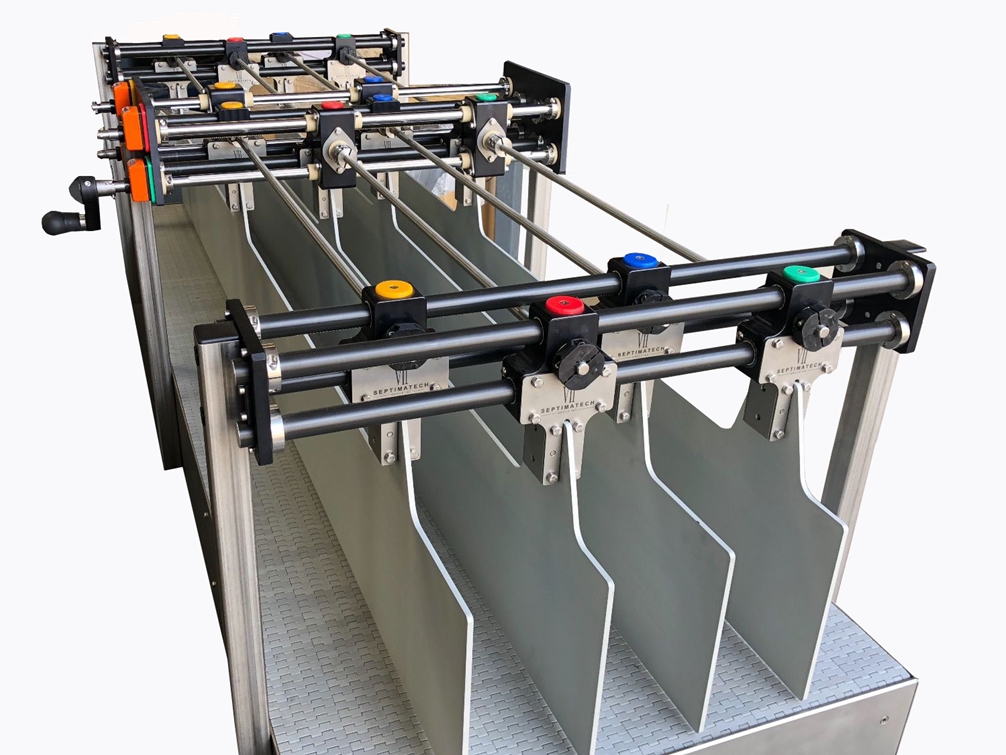

Multi-Lane Guide Rail Adjustment Systems |

|

|

Septimatech’s new Multi-Lane Guide Rail Adjustment Systems eliminates change parts, lane spacers and heavy lifting equipment to allow quick, simple adjustment of packaging lines with multiple lanes. The patented system significantly improves overall efficiency and productivity by reducing changeover complexity and freeing up valuable plant space and operator time. One person can simultaneously adjust up to a 30-foot (9 m) section of lanes from one location in a fraction of the time it takes with a traditional system. A similar length of traditional multi-lane section typically takes two people 35-50 minutes to changeover. An operator can complete the same length changeover in less than 5 minutes without tools or heavy lifting. |

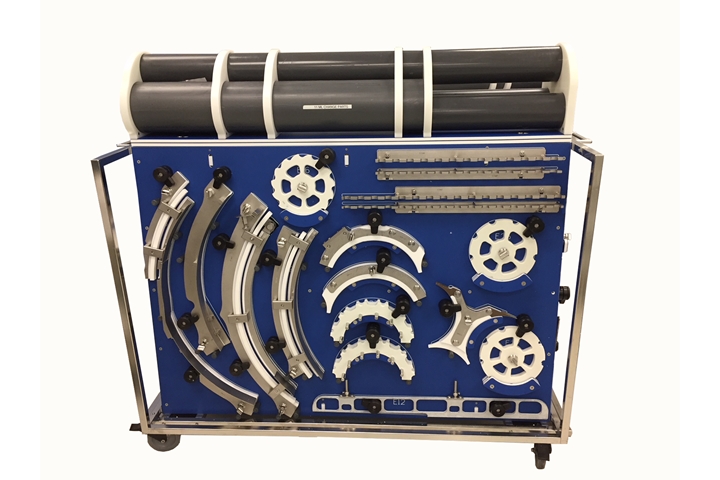

Smart Storage Cart |

|

|

Septimatech’s Smart Storage Systems provide maximum storage space and organization for change parts in a lightweight, transportable cart. With Smart Storage Systems, changeover parts are easy to identify, store, organize, clean, and protect from loss or damage. Large engraved part locations and Colour Coding allow for easy identification. Customers experience greater line changeover efficiency, less part loss and damage, improved ergonomics, and reduced operator handling time. |

Change Parts |

|

|

Rapid eXchange No Tool Change Parts (RXNT®) allow quick, efficient repeatable changeover of precisely engineered parts on packaging machines. The RXNT® system employs one-time installation of Nucleus components and Satellite parts designed for specific containers that quickly and easily lock into place without using tools. CNC routed Satellite parts provide pocket-to-pocket consistency for precise container handling. Customers typically receive 97 percent time savings, reducing changeovers from one hour to under five minutes. |

Feed Screws and Feed Screw Drive Systems |

|

|

Septimatech’s Feed Screws and Feed Screw Drive Systems are easily adaptable to any packaging machinery. A major beverage industry Customer reported that liquid spillage was reduced by 80 percent after installing Septimatech’s Feed Screws, resulting in a 20 percent increase in line speed and reduced costs from product loss. Septimatech’s Feed Screws and Feed Screw Drive Systems provide maximum performance for simple and complex applications and containers of any shape, whether you need to infeed, synchronize, group, combine, index, diverge, or rotate. |

| “For more than 25 years, Septimatech has delivered intelligent, easy-to-use solutions that are redefining the way customers manage packaging changeovers and view line efficiency,” says Gord Beaton, Septimatech VP of Sales and Service. “We help our customers overcome challenges that limit productivity and performance by helping them maximize machine and line efficiency and improve operator and machine interaction.” | |