5 Great Reasons to Upgrade Your Change Parts in 2026

Dec 17, 2025

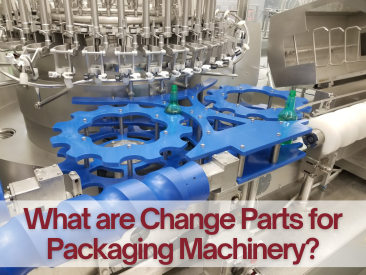

For some packaging operations, the decision to upgrade change parts is an afterthought until it’s time to run new containers or something breaks. Efficient interaction between your packaging machines and your containers depends on your change parts. Investing in them will benefit your business and help you get more value from your existing machines.

Here are 5 reasons why upgrading your change parts could be the best investment you can make to keep your machines in perfect working order and improve your bottom line.

1. Increased productivity

Older systems simply aren’t as fast or efficient as new ones. More importantly, change parts that are custom-made to fit your machine’s existing physical condition, packaged products, line functions and desired throughput improve container handling, reduce product loss and operate more effectively. Improving productivity with existing machine assets can provide significant business advantages.

2. Enhancements

Today technology exists to do things we couldn’t do in the past. A change parts specialist can provide enhancements that aren’t possible in older systems or frequently available in OEM change parts. This could be functionality for specific industries, or solutions for complex container control, challenging materials, or fast, repeatable changeovers. It could simply be ensuring you have the right change parts materials and design to ensure less parts wear or product damage at critical touch points.

Septimatech engineers enhancements into its change parts not available by most OEMs and competitors. We work closely with our customers to deliver change parts that provide competitive advantage for their specific challenges.

3. Greater Efficiency

Change Parts are available that simplify changeovers, increase flexibility to run multiple products on the same change parts, eliminate installation errors, reduce friction and ergonomic risk, among other factors that threaten efficiency. For example, Quick Change Parts ensure one-way installation for fast, simple, repeatable machine changeover that eliminates operator variables and downtime. Custom-engraving and color-coding provide fast, easy identification. Thoughtful design, surface finishing and material choices facilitate compact footprints for easy storage, transport and cleaning. Standardizing on Septimatech Quick Change Parts promote common changeover processes across all packaging machines regardless of make and model which results in reduced product loss and operator errors, faster changeovers, and less downtime.

4. Reduced Costs and Lead Time

Upgrading may seem expensive, but the truth is older systems have more issues and consequently more costs. Disruption caused by inefficient or less than optimum change parts and systems create downtime, frustrate employees, and cost more in the long run. Change parts that provide fast, repeatable changeovers and operate more effectively provide a substantial return on investment. Septimatech customers frequently report double-digit improvements in OEE, throughput, changeover time, and product loss or damage.

When you need new change parts, lead time is crucial to preventing downtime and creating unnecessary costs. Septimatech has excellent turnaround time on OEM replacement and Quick Change Parts.

5. Expert Changeover and Container Handling Support

Septimatech has enhanced container control and performance on more than 2,700 different machine models on hundreds of lines worldwide. We spend time to understand what isn’t working with your change parts and what improvements are required. We use digital measurement equipment to create a 3D model of your machine while at your site to ensure quality and lead times that are faster than most OEMs and competitors.

We validate all design concepts with advanced simulation of container travel to ensure precise motion and container control. We thoroughly test our solutions and your change parts to ensure they provide maximum performance. Our experienced team is committed to ensuring you receive performance and productivity that delivers competitive advantage from your packaging operations.

How Septimatech Can Help

It’s vital to find a partner that looks at the business benefits of your packaging solutions, not must the technology. Septimatech has more than 31 years experience providing change part and feed screw solutions for a wide-range of pharmaceutical, consumer and industrial companies worldwide.