Change Parts Storage Solutions Designed for Versatility in Pharmaceutical Changeovers

Dec 12, 2024

In pharmaceutical manufacturing & packaging, hygienics and compliance are paramount. Yet, amid advancements in automation and packaging technologies, one fundamental challenge persists: effective storage and management of change parts. Without a reliable storage system, even the most sophisticated machinery can suffer from downtime, inefficiency, and product quality issues.

The Challenge of Change Parts Storage in Pharmaceutical Lines

Pharmaceutical production lines require frequent changeovers to accommodate different products, batch sizes, and packaging formats. Each changeover demands specific machine parts tailored to the product being processed. These change parts are often:

- Numerous and Complex: Change parts can vary greatly, often being very small or large and shared among many SKUs, thus making them difficult to store in an organized manner.

- Prone to Damage: Without secure, designated storage, parts are susceptible to nicks, scratches, or contamination, compromising their integrity.

- Difficult to Track: Misplaced or incorrectly identified parts can delay production and increase the risk of costly errors.

- Compliance-Sensitive: Given the stringent FDA requirements and cleanroom standards in pharmaceutical manufacturing, change parts must be stored in a way that supports cleanliness and traceability.

- Batch Cross Contamination - Due to strict regulatory guidelines, change parts cannot be in any way cross contaminated between batches.

Improper storage of machine change parts

leads to inefficient changeovers, un-hygienic conditions, prolonged downtime, and even product loss — all of which hinder a manufacturer’s ability to meet demand and maintain compliance.

The Solution? Precision-Engineered Change Parts Storage Carts from Septimatech.

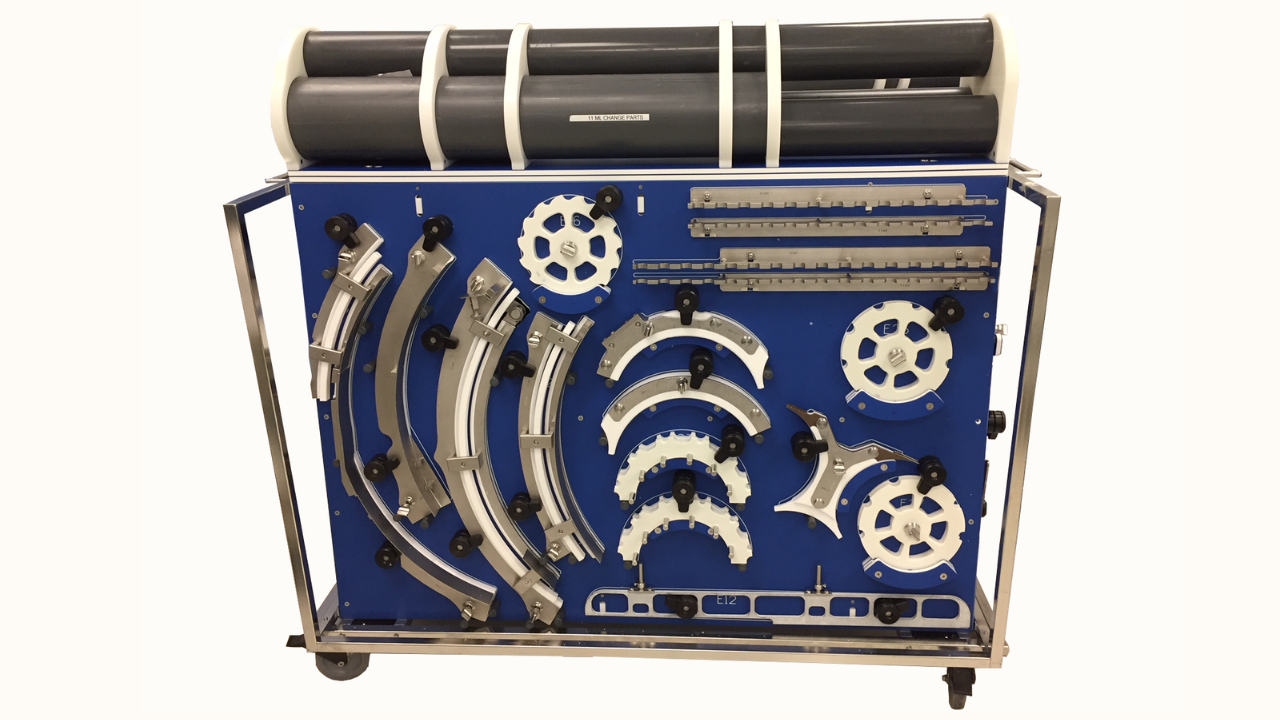

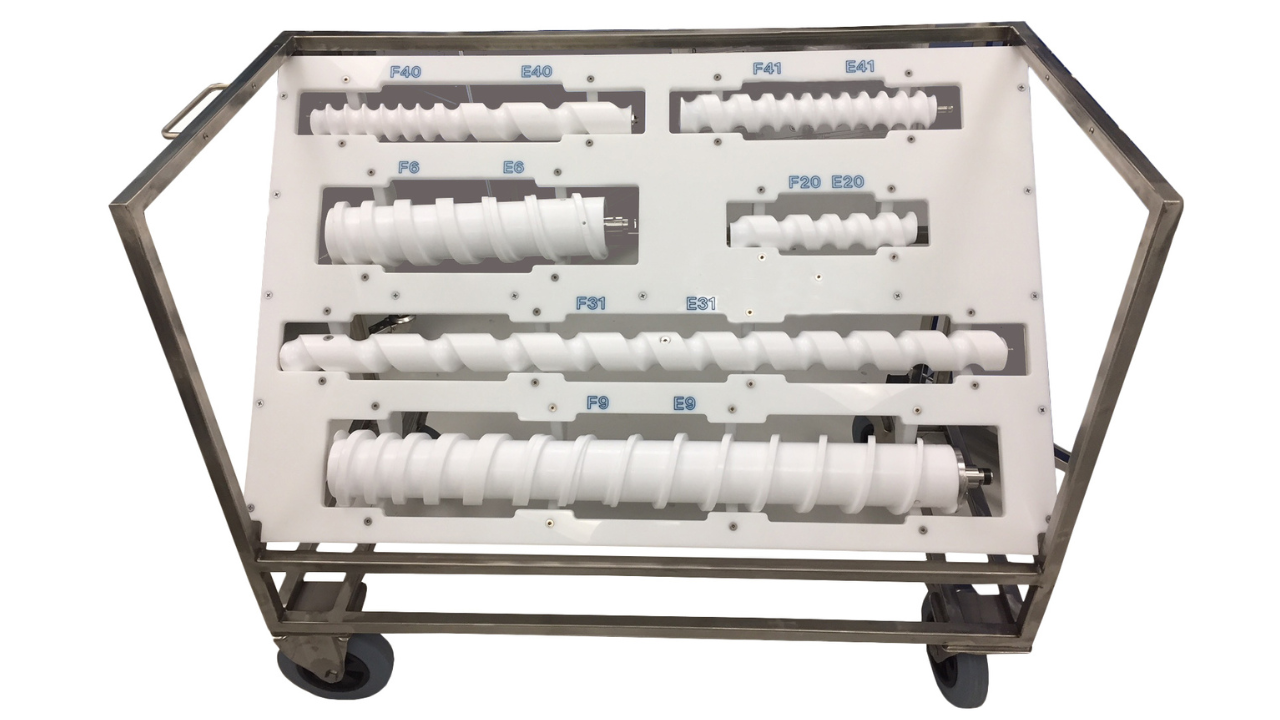

Septimatech’s precision-engineered change parts storage carts provide a streamlined solution to these challenges, offering versatility, organization, and compliance that pharmaceutical lines require. These storage solutions are designed with the unique needs of pharma manufacturers in mind and address the following pain points:

Damage Prevention

Each cart is custom-designed to securely hold specific change parts, reducing the risk of damage during storage or transport. Materials and finishes, such as electro-polishing and 316L stainless steel passivation, ensure surfaces remain compliant with cleanroom standards and protect parts from contamination.

Efficient Organization

Clearly labeled and compartmentalized spaces for each part ensure operators can quickly identify and retrieve what they need. This organization minimizes the chance of errors and accelerates the changeover process.

Mobility and Flexibility

These carts are designed for ease of movement, allowing change parts to be transported seamlessly between storage and production lines. Their adaptability supports the frequent changeovers required for diverse product runs, including injectables and personalized medicines.

Compliance-Friendly Design

Septimatech’s solutions are crafted to meet FDA requirements and cleanroom standards. Hidden fasteners, conical surfaces, and smooth finishes help prevent product pooling and facilitate easy cleaning, ensuring compliance and product safety.

Maximized Uptime

By reducing the time spent locating and handling change parts, these storage carts help minimize downtime and maximize throughput — all while complying to hygienic regulations, which is essential in a fast-paced, competitive pharmaceutical environment.

Achieve Seamless and Reliable Changeovers

As pharmaceutical manufacturers face increasing demand for flexibility and hygienic compliance, reliable change parts storage is no longer a luxury — it’s a necessity. Septimatech’s precision-engineered storage solutions empower manufacturers to handle changeovers confidently, protect valuable parts, and maintain the high standards of a regulated industry.

With organized, versatile storage systems in place, pharmaceutical manufacturers can focus on what truly matters: delivering safe, high-quality products to customers efficiently and reliably.