Improve Your Productivity and Flexibility with a Limited Workforce

Aug 29, 2022

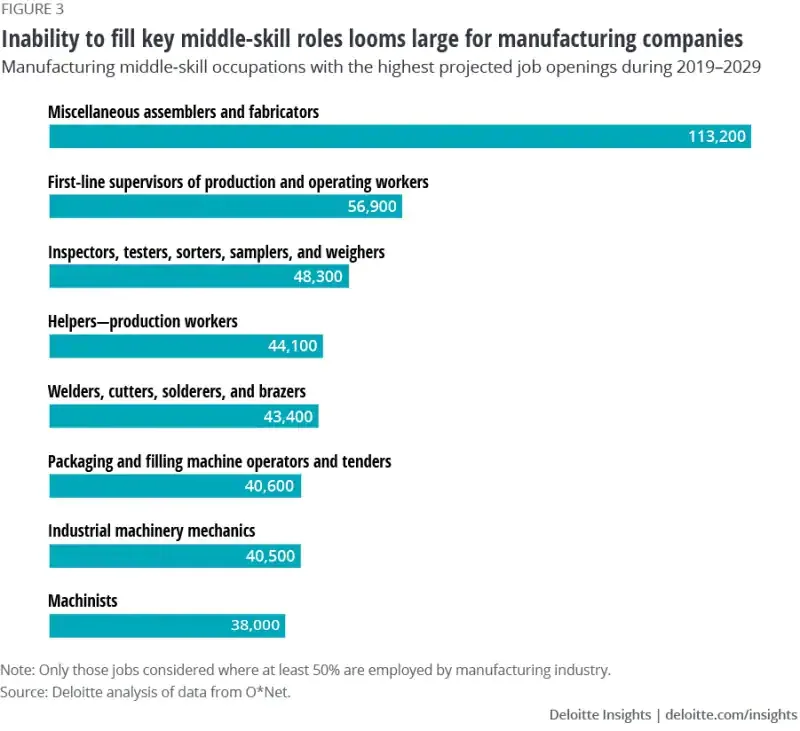

If wishes were workers. If only it were that easy. Ask manufacturers facing labor shortages and they would likely agree. According to many experts, today’s labor shortages are likely here to stay even after the acute crisis created by the COVID pandemic passes—particularly the need for skilled workers. In a 2021 study by Deloitte and The Manufacturing Institute, they state U.S. manufacturers are expected to have 2.1 million unfilled jobs by 2030—packaging operations included. The labor shortage crisis is especially acute in frontline industries with mission-critical or 24/7 operations that rely heavily on hourly workers.

Labor Shortage?

So, if the labor shortage in manufacturing is here to stay, what can you do to use your existing team more wisely and use less labor where possible?

Here are 3 ways the right changeover solutions can help you overcome labor shortages and create a more productive, flexible and resilient packaging operation.

Help Existing Team Work Smarter and More Efficiently

Changeover solutions that are fast, accurate and repeatable eliminate operator judgement calls that can lead to frequent fine tuning. Continued adjustments after container changeovers, to get a line running at peak performance, are one of the leading causes of downtime, poor production, and product loss. In PMMI’s 2018 Beverage Trends Survey, one respondent highlighted that it can take 3-6 hours to fine-tune their line on top of the 8-10 hours they spend on equipment changeover when they change containers.

Easy Adjust Guide Rails and Cap Chutes allow one person to precisely adjust 80 feet of line from one location, including tight radius curves, corners and crossovers in less than 10 seconds. Multi-Lane Guide Rail Adjustment solutions allow one person to simultaneously adjust a 30 foot section of Case Packer accumulation lane dividers and lane guides from one location. Typically, a similar section of divider rails and lane guides would take two people 35-50 minutes to adjust to the proper settings.

Easy-to-use standardized changeover solutions also simplify cross-training and free up skilled workers to focus on other high priority tasks.

Working smart and efficiently by using your workforce in a more value-added way is the first step to improving productivity without increasing labor. Our customers improve production throughput, with existing or less labor, by implementing more efficient changeover and container handling solutions. Our Adjustable Guide Rail Customers realize an ROI in less than a year based on just three, 30-minute changeovers per week.

Increase Productivity Without Increasing Labor

Small improvements can often be implemented quickly and cost effectively with great results. Eliminating just one step in a frequently performed task or changing how you store, and transport change parts can have a huge impact on productivity. Line Audits are an effective way to analyze changeover processes, change parts performance, and container handling to help improve function and efficiency or add flexibility to specific machines or your line. Septimatech provides Line Audits for many of its customers. We’ve improved performance and productivity on more than 2,700 different machine models on hundreds of lines worldwide.

Change Parts and container handling solutions are available that simplify changeovers, increase flexibility to run multiple products on the same change parts, eliminate installation errors, reduce friction and ergonomic risk, among other factors that threaten efficiency. For example, Quick Change Parts ensure one-way installation for fast, simple, repeatable machine changeover that eliminate operator variables and downtime. Custom-engraving and color-coding provide fast, easy identification for installing the proper change parts. Thoughtful design and ergonomics facilitate compact footprints for easy storage, transport and cleaning of change parts. Standardizing on Quick Change Parts promote common changeover processes across all packaging machines regardless of make and model which results in reduced product loss, faster changeovers and less downtime.

Easy Changeover and 5S Change Parts Carts reduce changeover time by keeping parts organized and making them easy to transport and clean. Easy Changeover Carts are user-configurable for cost-effective versatility. 5S Carts incorporate lean manufacturing and Six Sigma principles to match your unique changeover processes for ultimate efficiency.

Create a More Ergonomic and Productive Work Environment

Simplifying changeovers so they are faster, less strenuous, and more productive create a more pleasant work environment. Freeing your skilled staff from unnecessarily difficult tasks will let them focus on the work they are trained for – plus, they’ll be happier for it which leads to higher retention and productivity.

For example, Multi-Lane Guide Rail Adjust Systems eliminates difficult to install change parts, spacers, templates and heavy lifting that causes unnecessary downtime, ergonomic risks and expense. It can precisely adjust 30 feet of lane guides simultaneously from one location in seconds.

Easy Changeover and 5S Change Parts are one of the most cost-effective ergonomic improvement s to your changeover process. They keep parts organized, maneuver easily in tight spaces, even on rough and uneven surfaces, and provide safe ergonomic loading and unloading.

Investing in machine and line solutions that simplify changeovers or reducing the amount of human effort required is frequently a better way to create a resilient packaging operation than eliminating labor altogether. This allows you to use your workforce’s skills where they can most positively impact production, retrain as necessary and implement technology that creates flexibility and efficiency.

How Septimatech Can Help

It’s vital to find a partner that looks at the business benefits of your packaging solutions, not just the technology. Septimatech has nearly 30 years’ experience providing changeover and container handling solutions that improve productivity and increase performance and flexibility. We spend time to understand what isn’t working and what improvements are required. Our experienced team is committed to ensuring you receive changeover solutions that deliver competitive advantage.

Contact us today www.septimatech.com to learn how we can help you better manage labor shortages and get the most value from your machine and packaging line investment—today and tomorrow.