Products On Display - Pack Expo Chicago 2024

Sep 12, 2024

See Septimatech Changeover and Container Control Solutions at Pack Expo International 2024. Visit us at booth N-5136.

Septimatech precision-engineered solutions simplify operations, improve container control, and assure fast, accurate, repeatable changeovers in even the most challenging production environments.

- Quick Change Parts deliver fast, accurate, repeatable machine changeovers in less than 5 minutes – a 97 percent time savings for most customers.

- Easy Adjust Guide Rail® System deliver fast, accurate, repeatable guide rail adjustment and changeover with less labor when installed on existing or new conveyor systems.

- Easy Changeover Carts provide user-configurable change parts storage and transport.

- Easy Adjust Tight Radius Corners deliver fast, repeatable changeovers and superior container control for 90 and 180 degree corners.

- Multi-Lane Guide Rail System eliminates change parts, spacers and heavy equipment to simplify changeovers with fast, accurate, repeatable lane adjustments by one person.

- Dual/Single Feed Screw Drives and Feed Screws deliver perfect, container control, timing and sequencing for any dual and single feed screw application.

- Easy Adjust Cap Chutes deliver fast, simple cap chute guide changeovers and superior control for any type closure.

- Improve Your Productivity and Flexibility with a Limited Workforce How Changeover Solutions Can Help You Overcome Labor Shortages on Your Packaging Line.

Register for free TODAY using code 26V79:

Quick Change Parts

Septimatech Change Parts allow quick, efficient repeatable changeover of precisely engineered parts on packaging machines. The Quick Change system employs one-time installation of Nucleus components and Change Parts designed for specific containers that quickly and easily lock into place without using tools. Customers typically receive 97 percent time savings, reducing changeovers from one hour to under five minutes.

Easy Adjust Guide Rail® Systems

Easy Adjust Guide Rails® deliver fast, repeatable guide rail adjustment, without pneumatics or high maintenance components. Increased efficiency, reduced labor & maintenance, & improved product handling combine to provide quick ROI & great TCO. Easy Adjust Guide Rails® easily fit on existing or new conveyor systems. Guide rail changes which take hours are reduced to minutes.

Feed Screws

Septimatech Feed Screws are tailor-made to your container control, timing and sequencing needs. Our industry leading experience in designing feed screw solutions combined with state-of-the art manufacturing, CAD simulation and testing ensure superior pocket-to-pocket accuracy and container flow. Smooth, low friction surfaces prevent scuffing and marking on labels and containers.

Dual/Single Feed Screw Drives

New redesigned Dual Feed Screw Drive Systems eliminate complex mechanical linkages above and below the conveyor for a compact, less intrusive footprint that’s easy to integrate and access. Dual Feed Screw Drives are available with digitally synchronized servos for high functioning intelligent applications or high-performance AC motor drives for all standard feed screw applications.

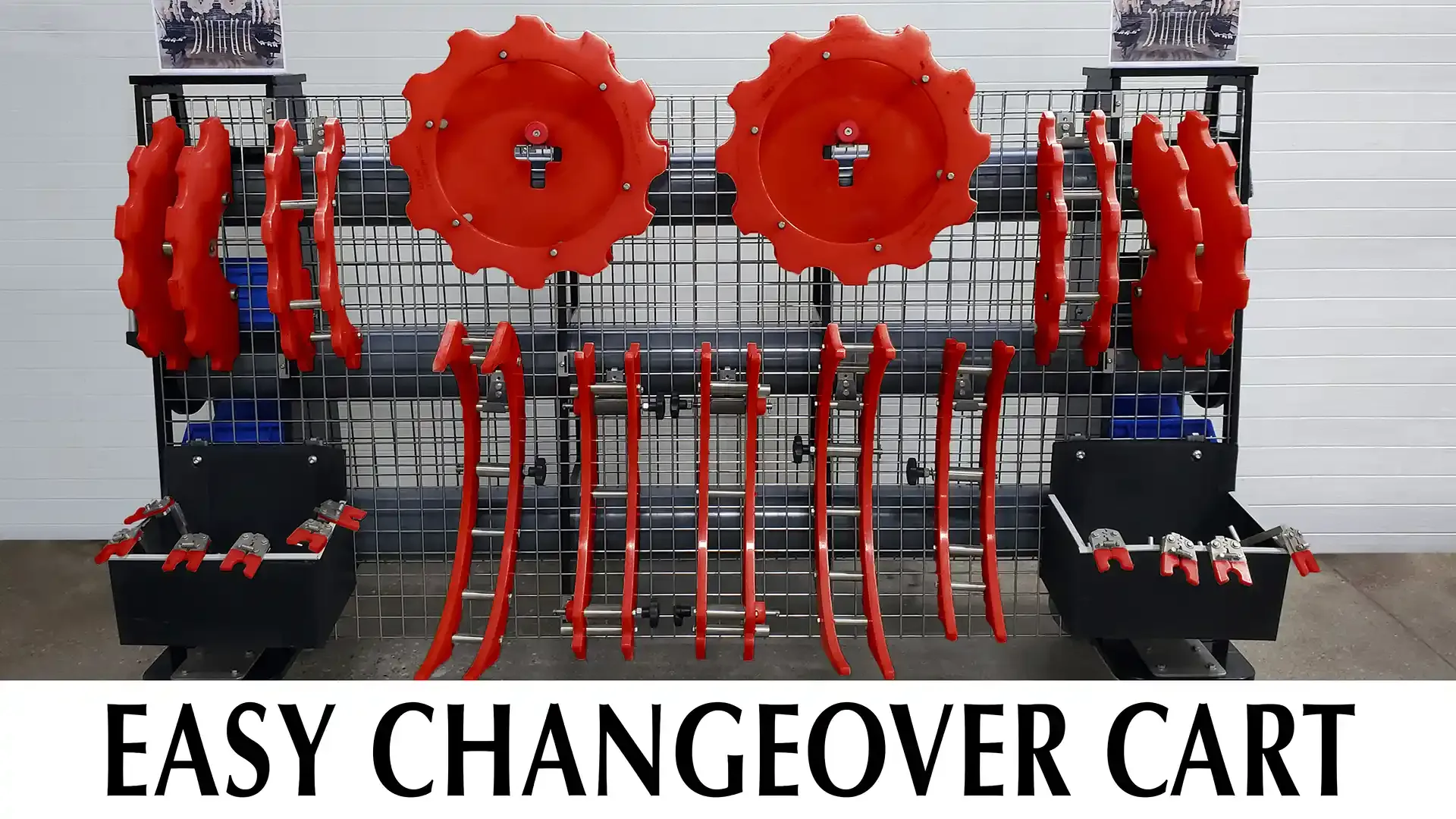

Easy Changeover Carts

Reimagine your Change Parts Storage with versatile user-configurable carts. Easy Changeover Carts provide fast, simple, orderly changeovers and unlimited versatility at a modest investment. Washdown ready design makes convenient on-cart change parts cleaning simple. High quality casters provide outstanding maneuverability, even on rough surfaces, and quickly change from non-swivel to swivel for in place pivoting and access to all sides.

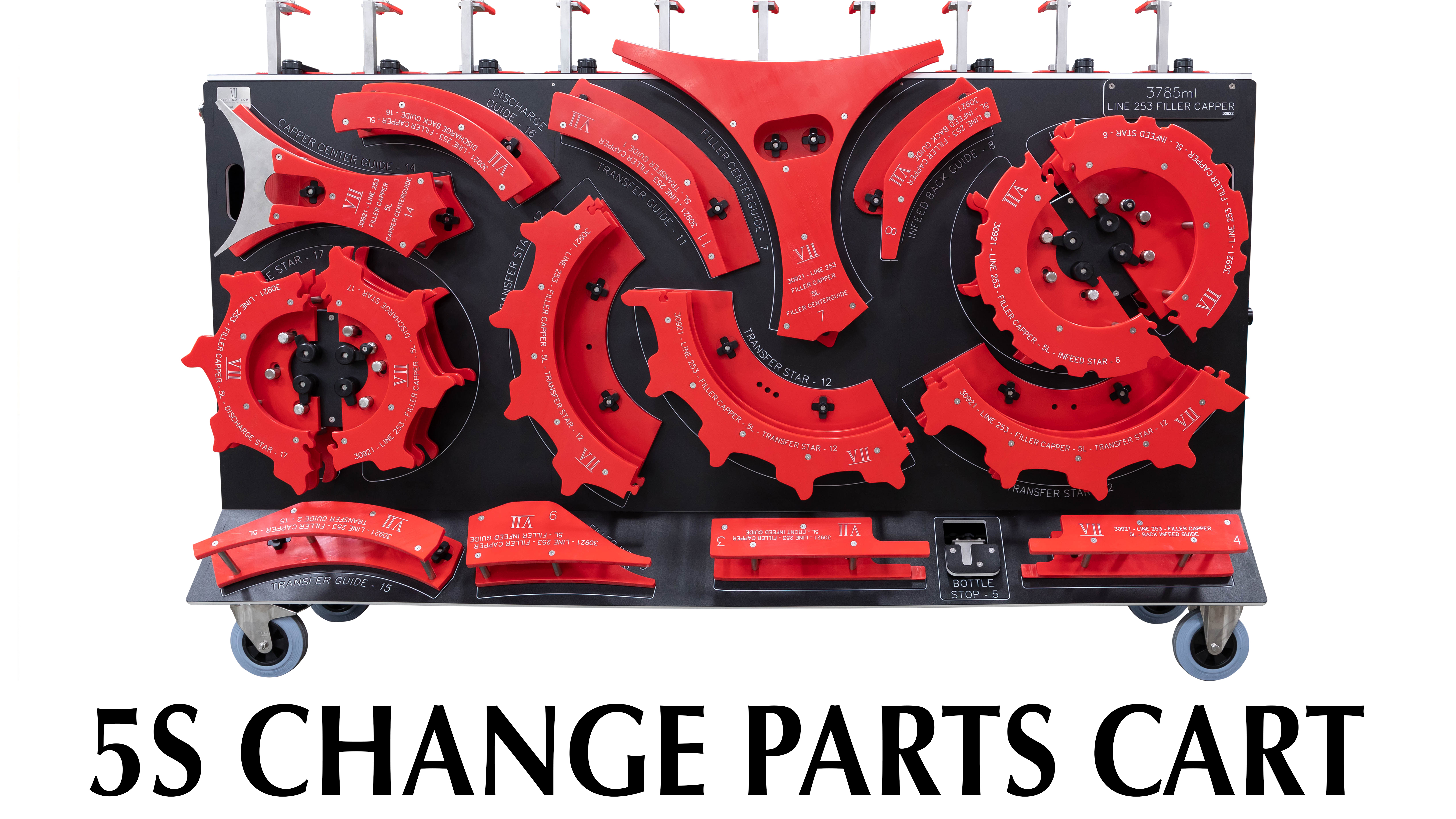

Custom 5S Changeover Carts

Septimatech 5S Change Parts Carts are custom-made to fit your changeover parts, processes and storage needs. Our 5S Carts are an ideal solution for pharmaceutical and food companies with strict clean room and FDA compliance requirements or any company with lean manufacturing or Six Sigma requirements.

Multi-Lane Guide Rail System

Septimatech’s new Multi-Lane Guide Rail System eliminates change parts, lane spacers and heavy lifting equipment to allow quick, simple adjustment of packaging lines with multiple lanes. One person can simultaneously adjust up to a 30-foot (9 m) section of lanes from one location in 5minutes. A similar length of traditional multi-lane section typically takes two people 35-50 minutes to changeover.