-

-

-

-

-

Need a Quote on a Solution?

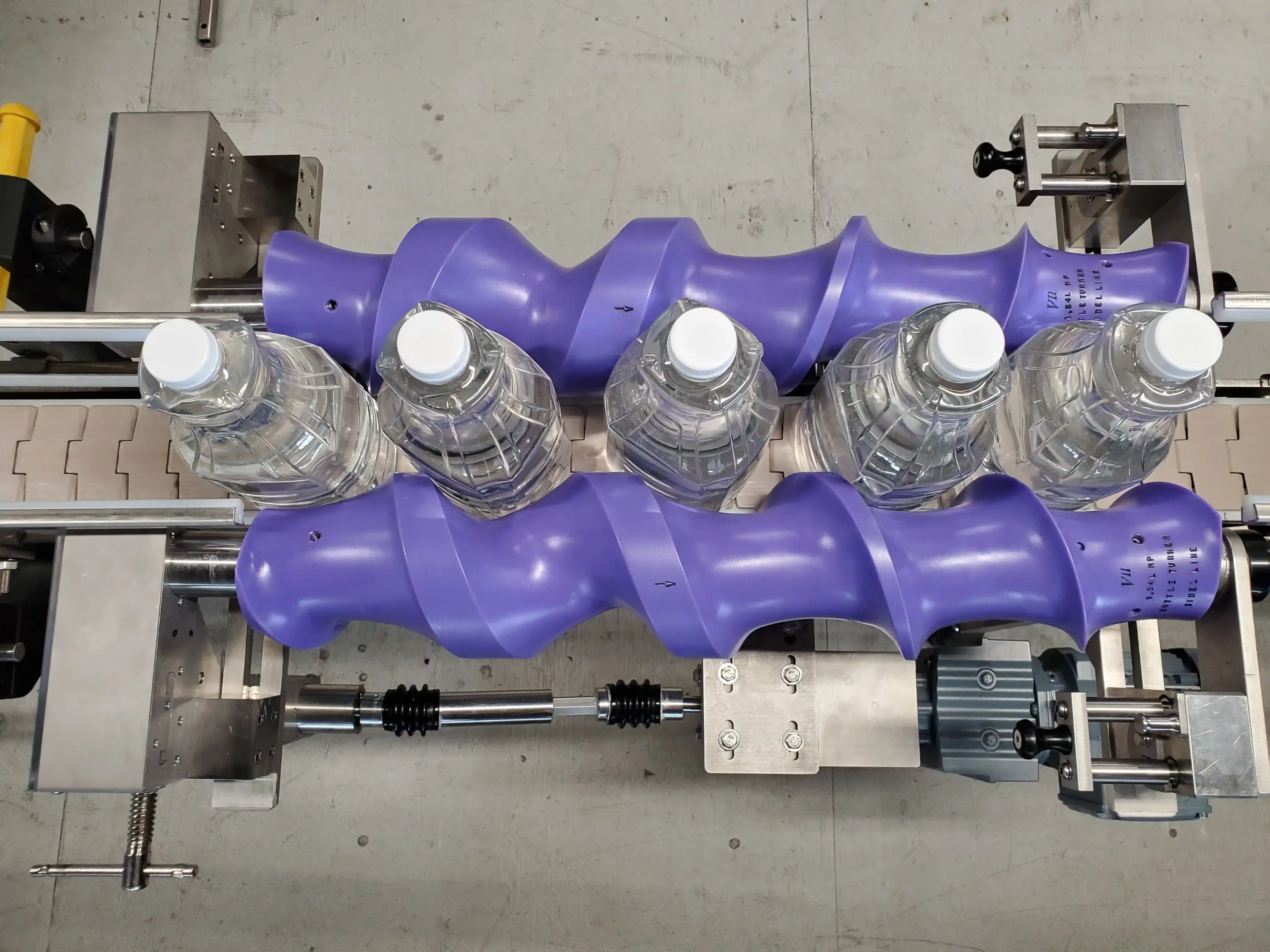

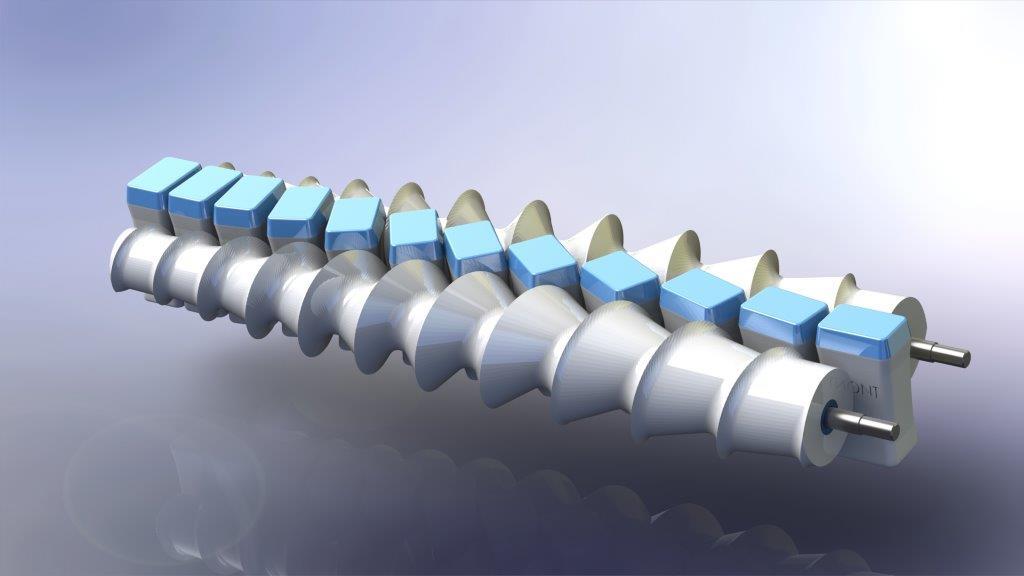

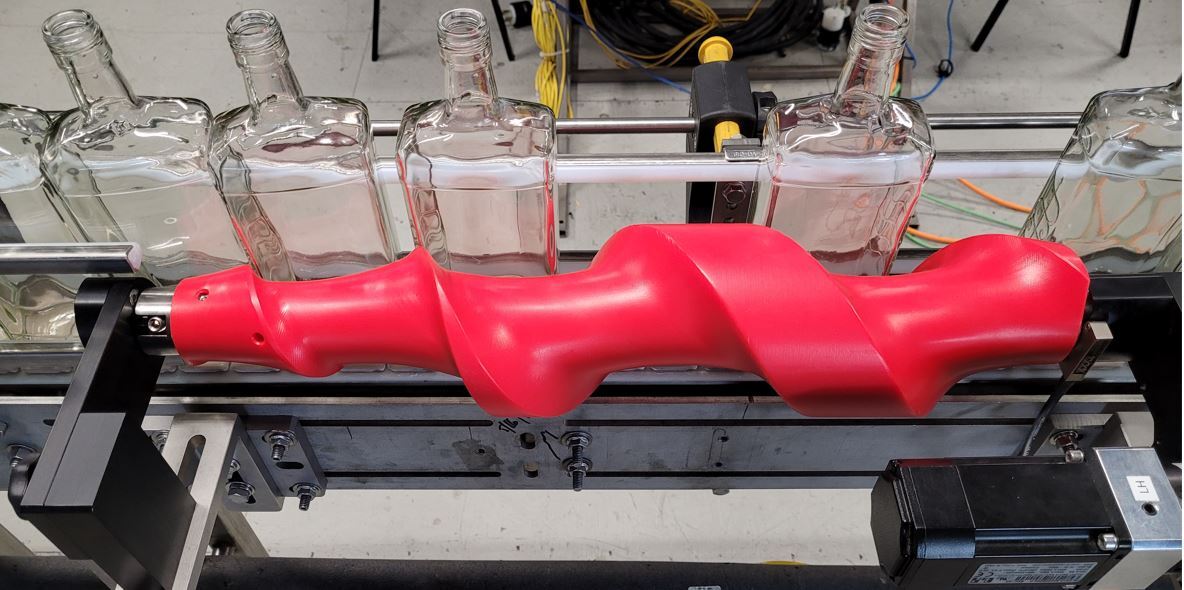

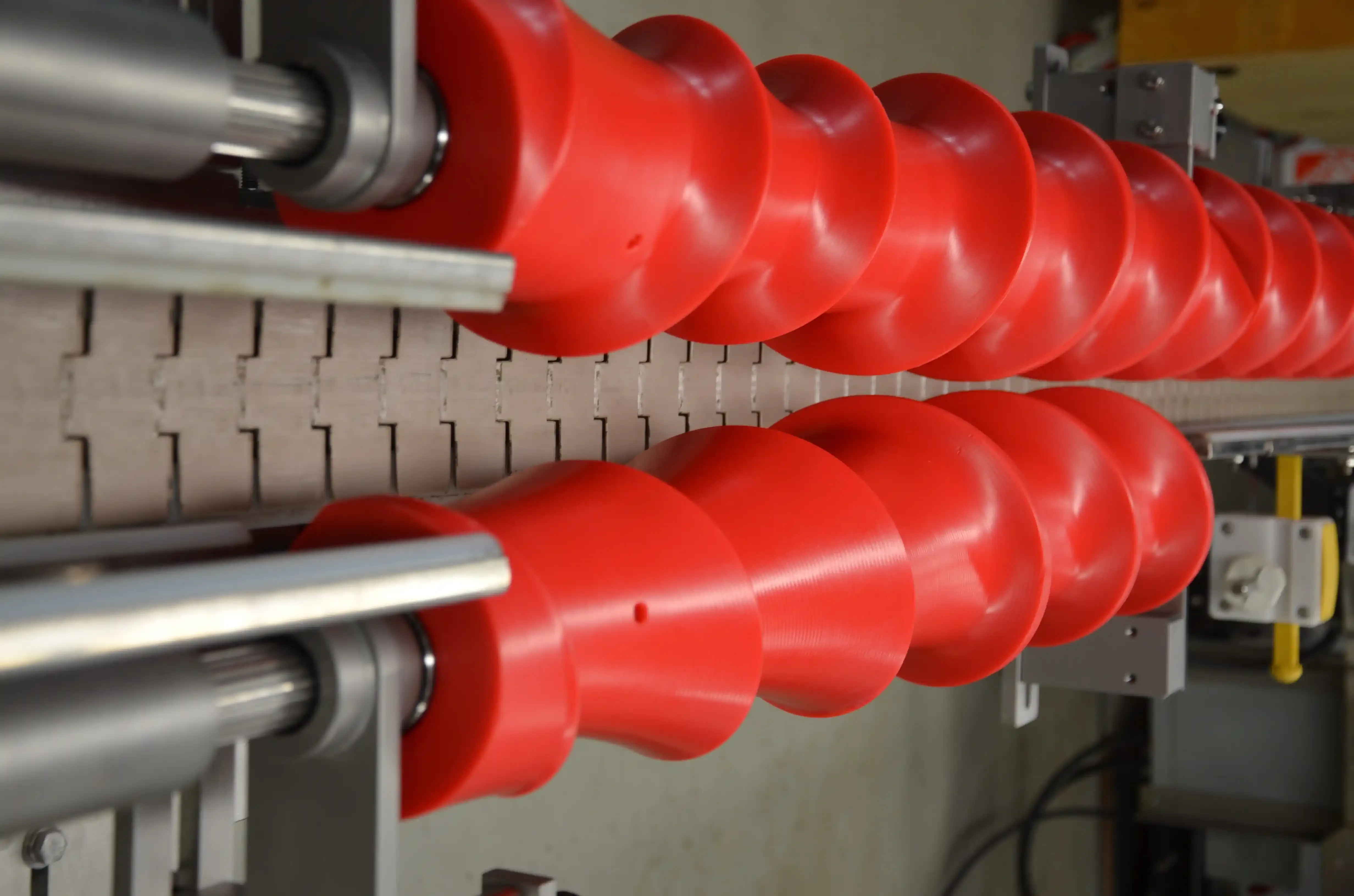

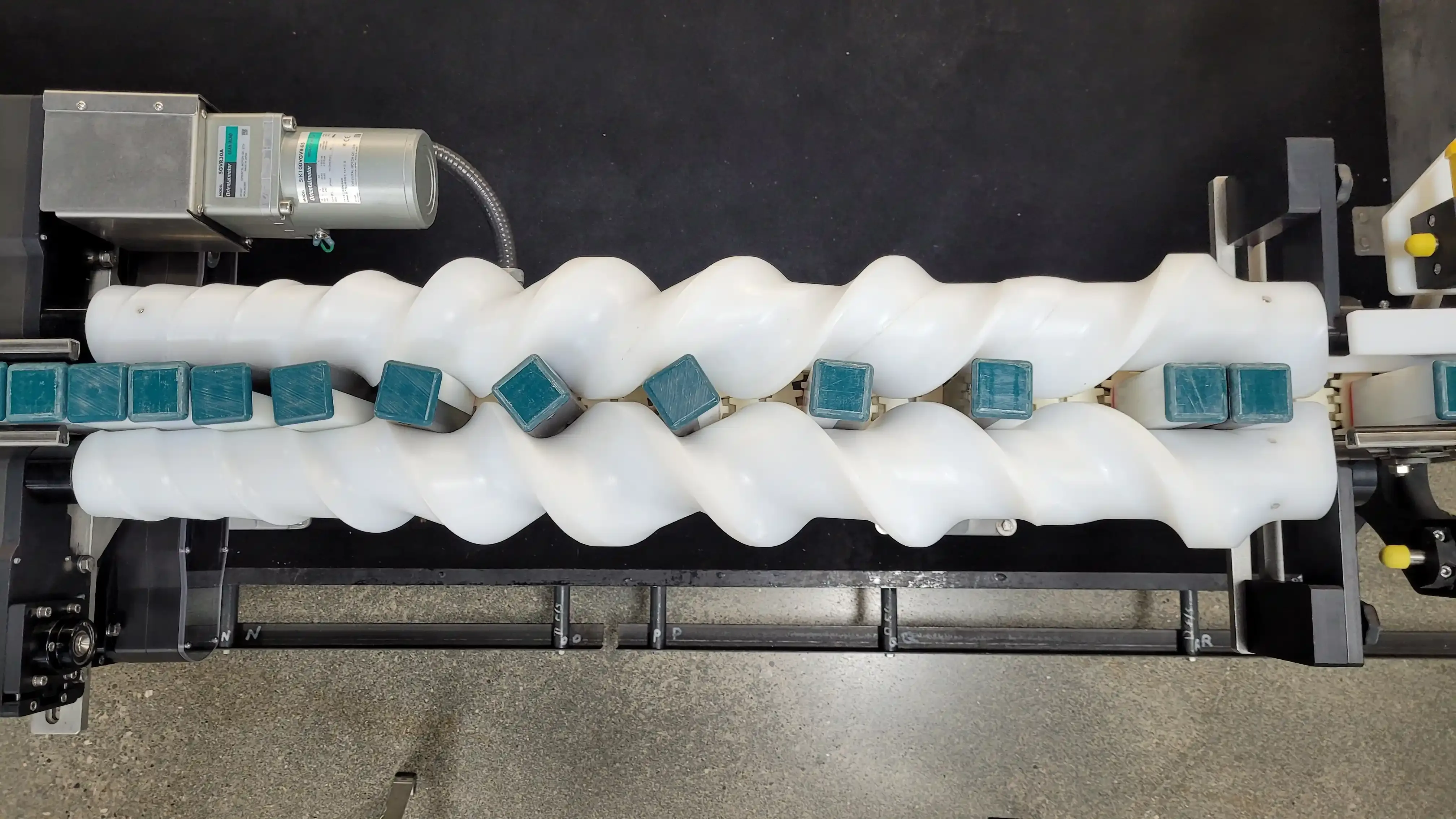

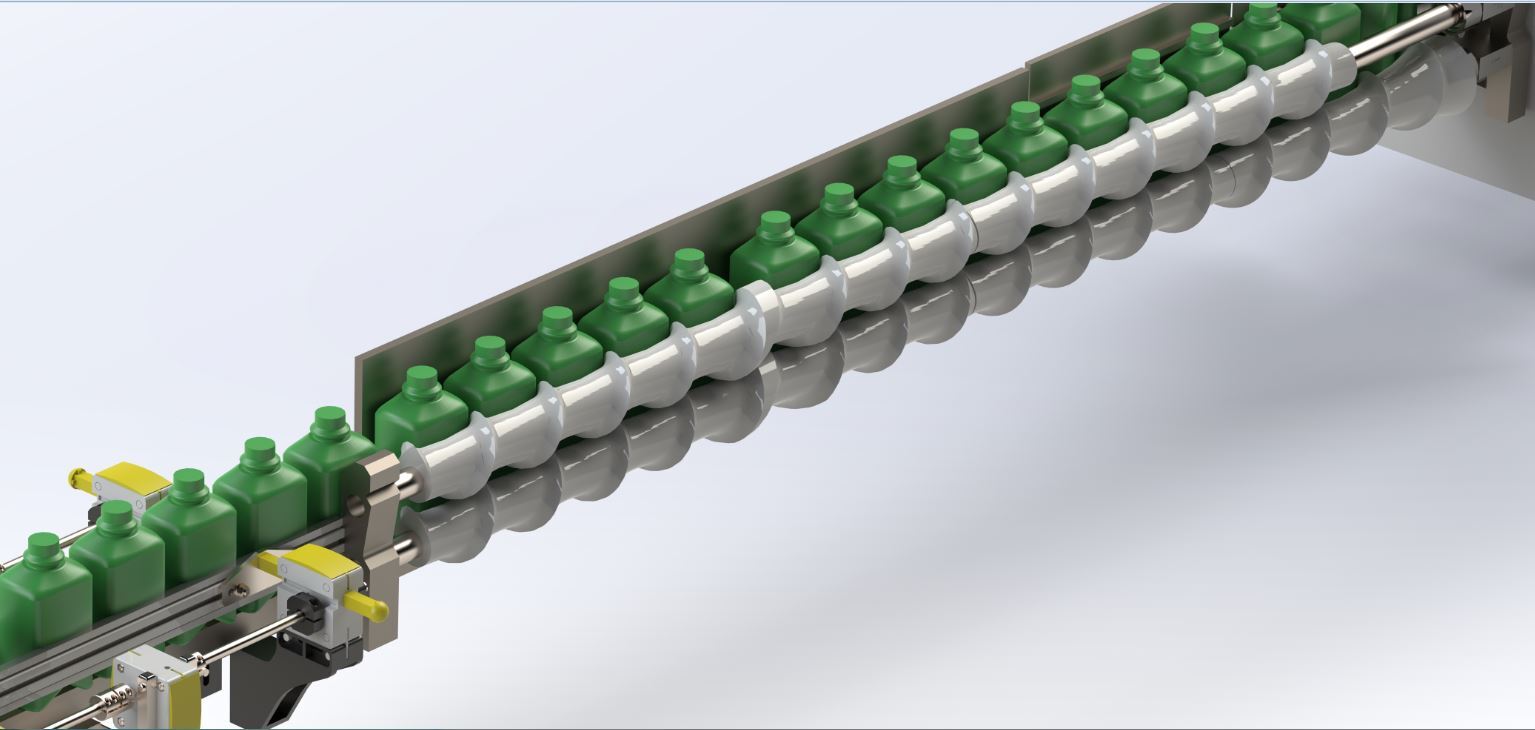

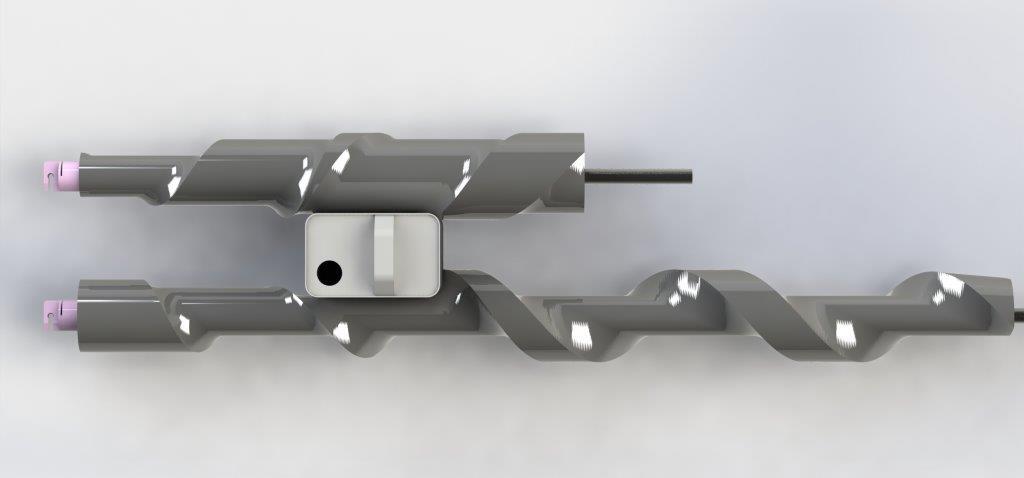

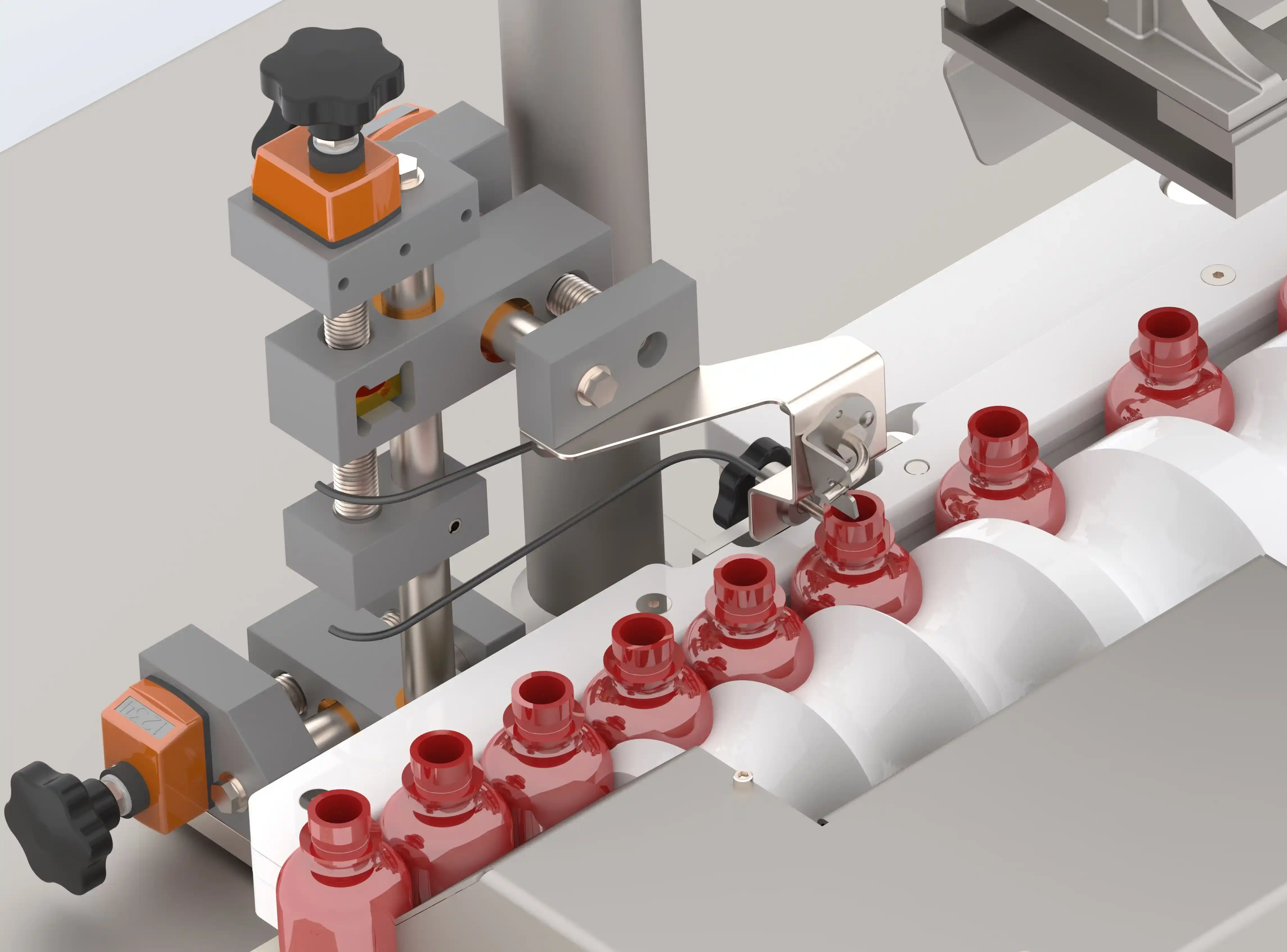

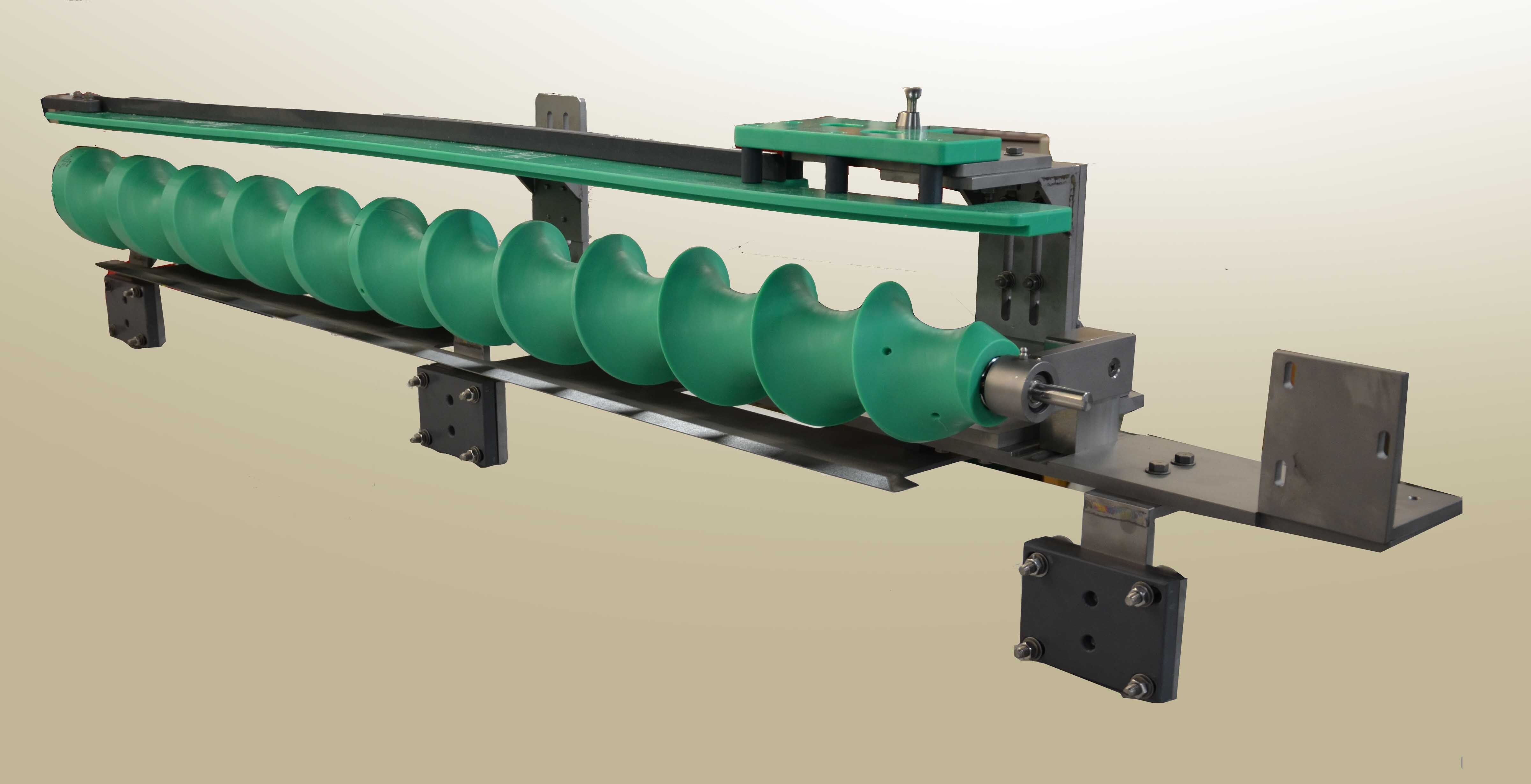

Feed Screws / Timing Screws

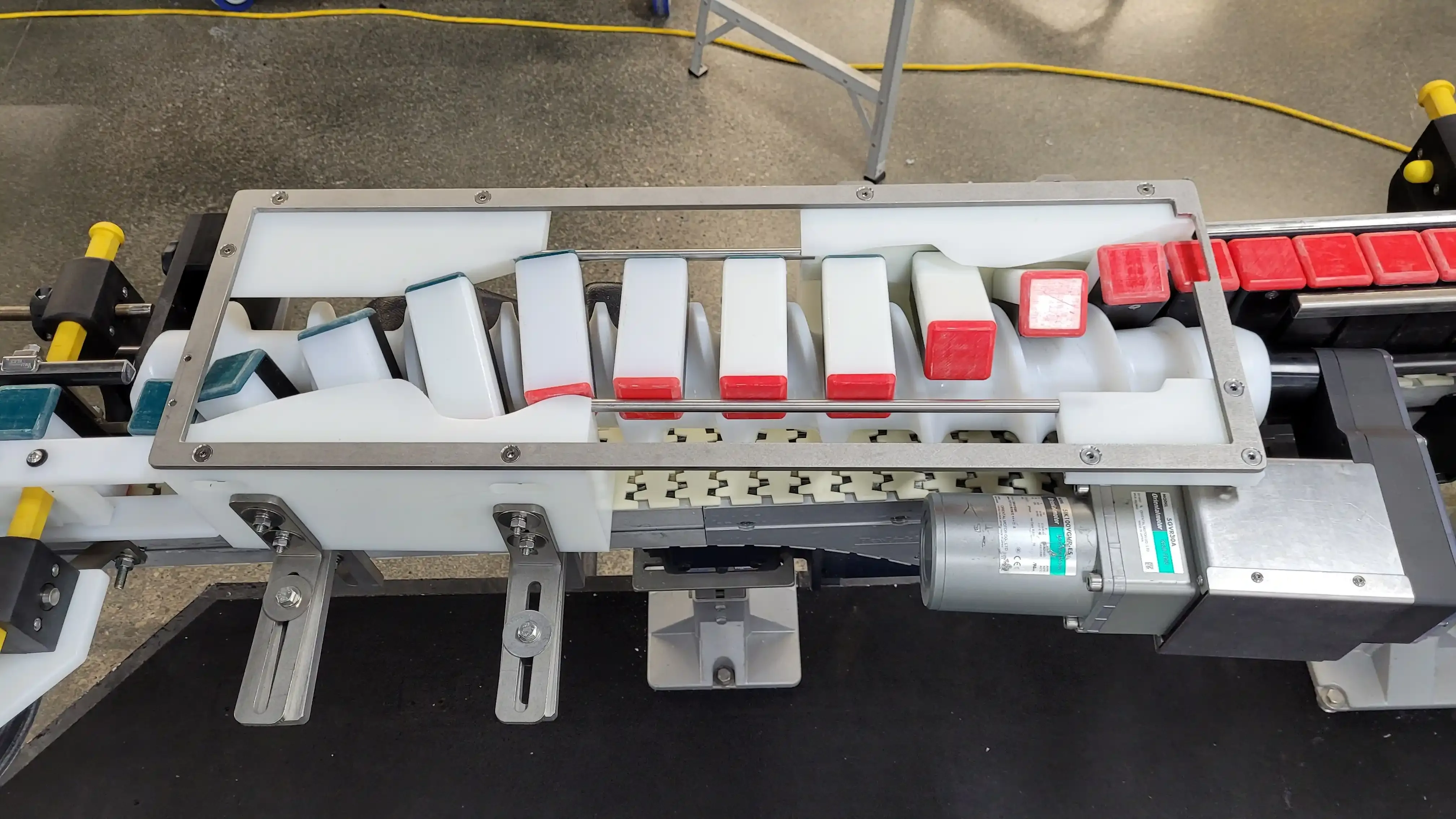

Timing / Sequencing, Indexing, Turning, Grouping, Tilting, Orienting, other applications.

Septimatech Feed Screws are custom-made to your container control, timing, denester, and sequencing requirements.

Our industry leading experience in designing feed screw solutions combined with state-of-the art manufacturing, CAD simulation and testing ensure superior pocket-to-pocket accuracy and container flow.

Smooth, low friction surfaces prevent scuffing and marking on labels and containers.

Whether you call your feed screws timing screws, scrolls, tornillos sin fin, worms, vis d’alimentation, infeed screws, gusanos or tornillos de alimentacion, or a helix, we offer quick lead times and cost-effective solutions for all your applications, regardless of container size and shape.

- Color-coding for easy identification

- Custom engraving

- Design and Manufactured for any machine make and model

- Plastic Feed Screws for Long-wear, abrasion resistant life

- Feeding, separating and timing

- Tilting for angled necks

- Inverting, rotating, twisting

- Container lay down

- Grouping, dividing, combining

- Machine-to-machine synchronization

- Denesters for Denesting containers

- Accelerating & Decelerating Timing Screws

- Enhanced container control and bottle handling

- Low friction, non-marking container travel

- Fast, tool-less changeover

- Precise pocket-to-pocket consistency

- Custom-made to your machine and application

- Short lead times

Ready for a Quote?

Take control of your container handling — request a timing screw quote.