-

-

-

-

-

Need a Quote on a Solution?

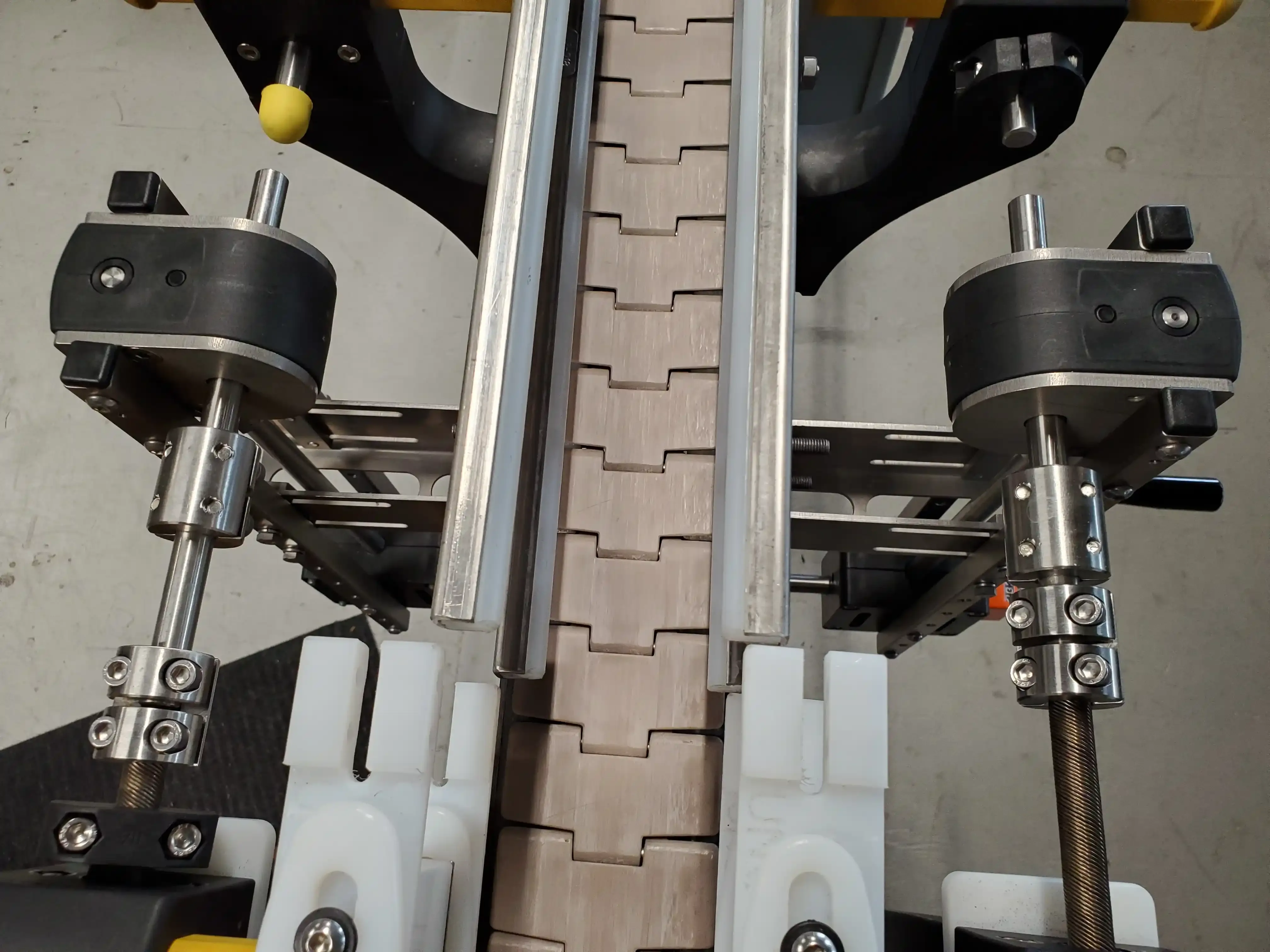

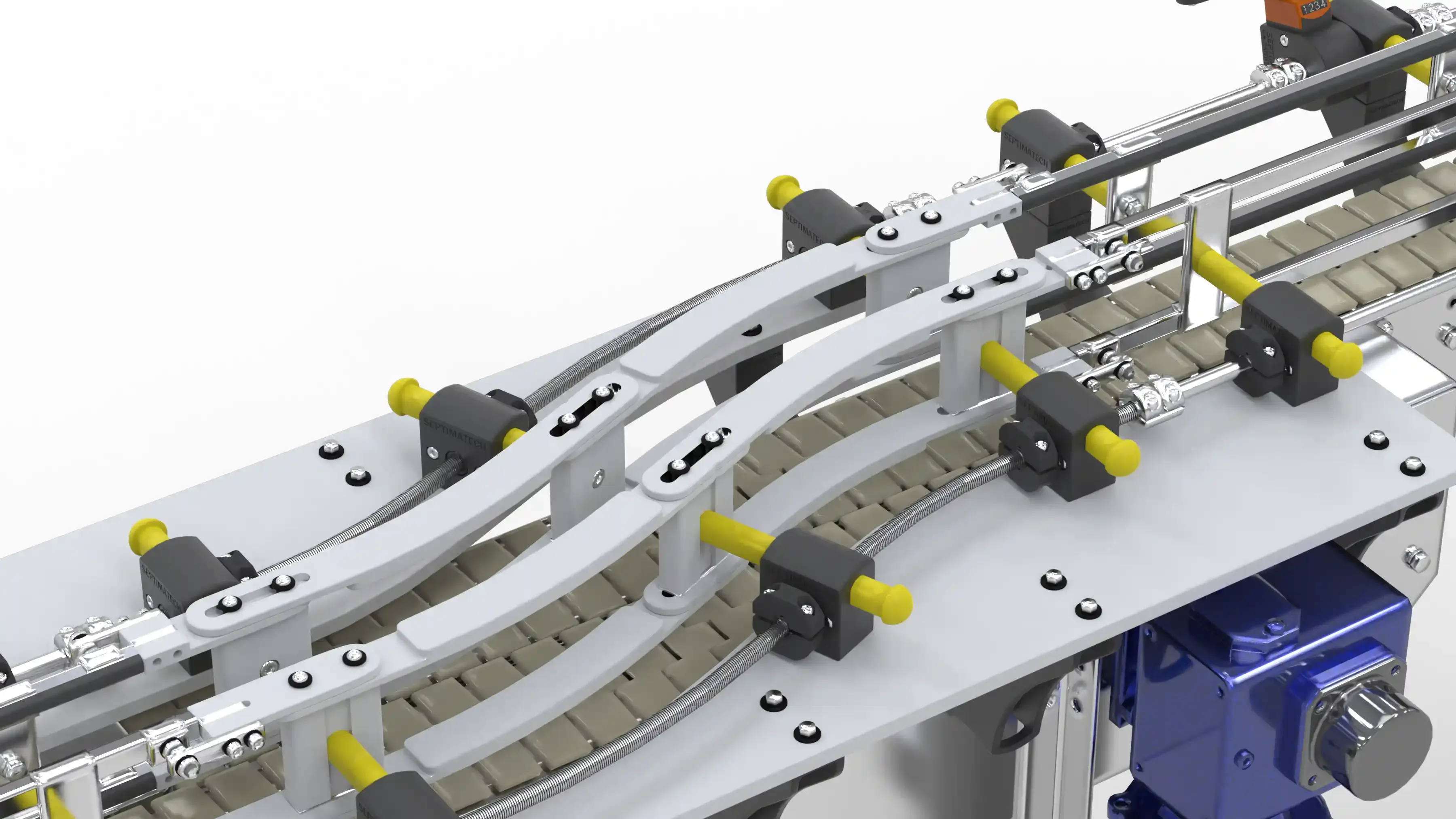

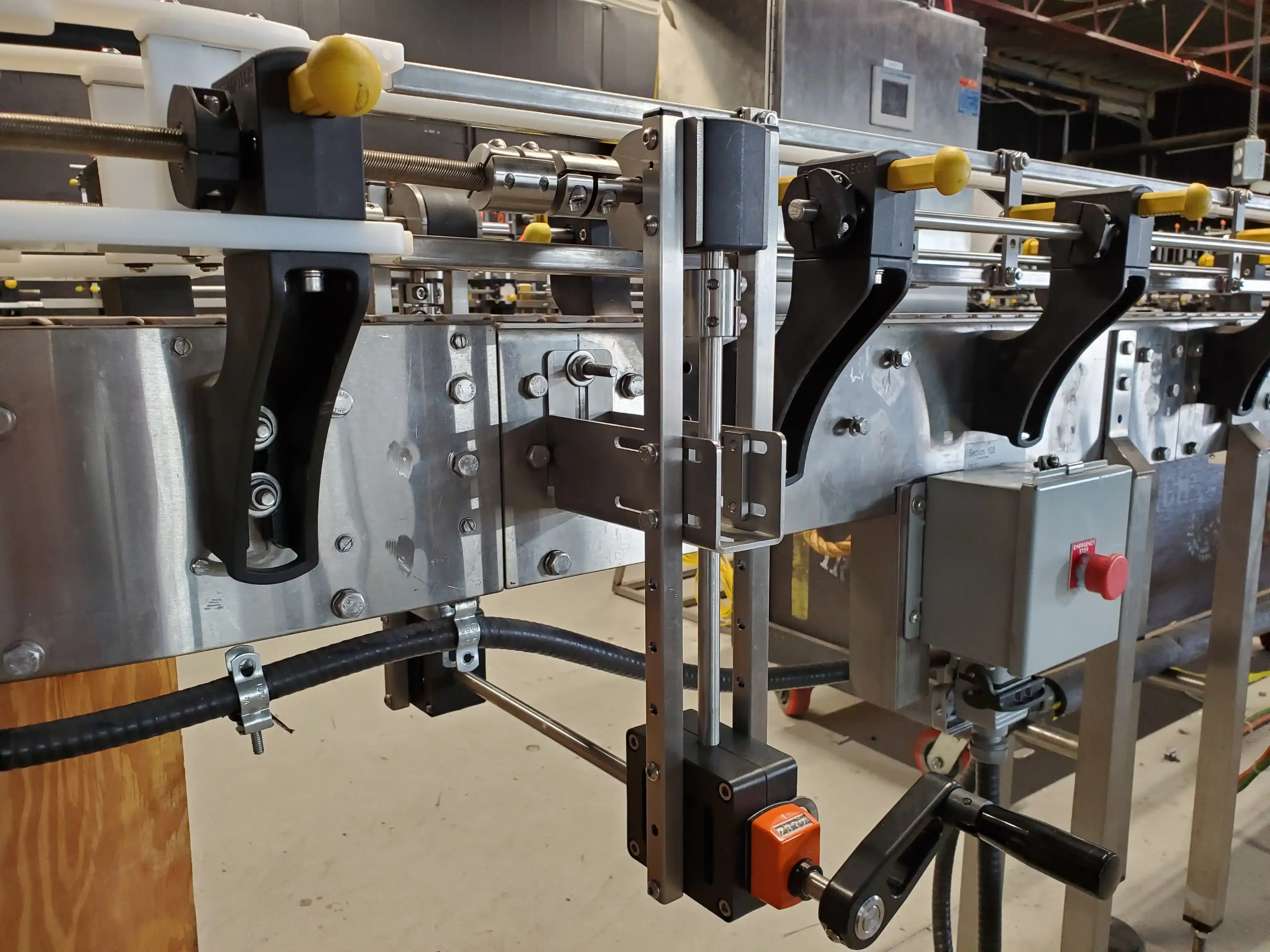

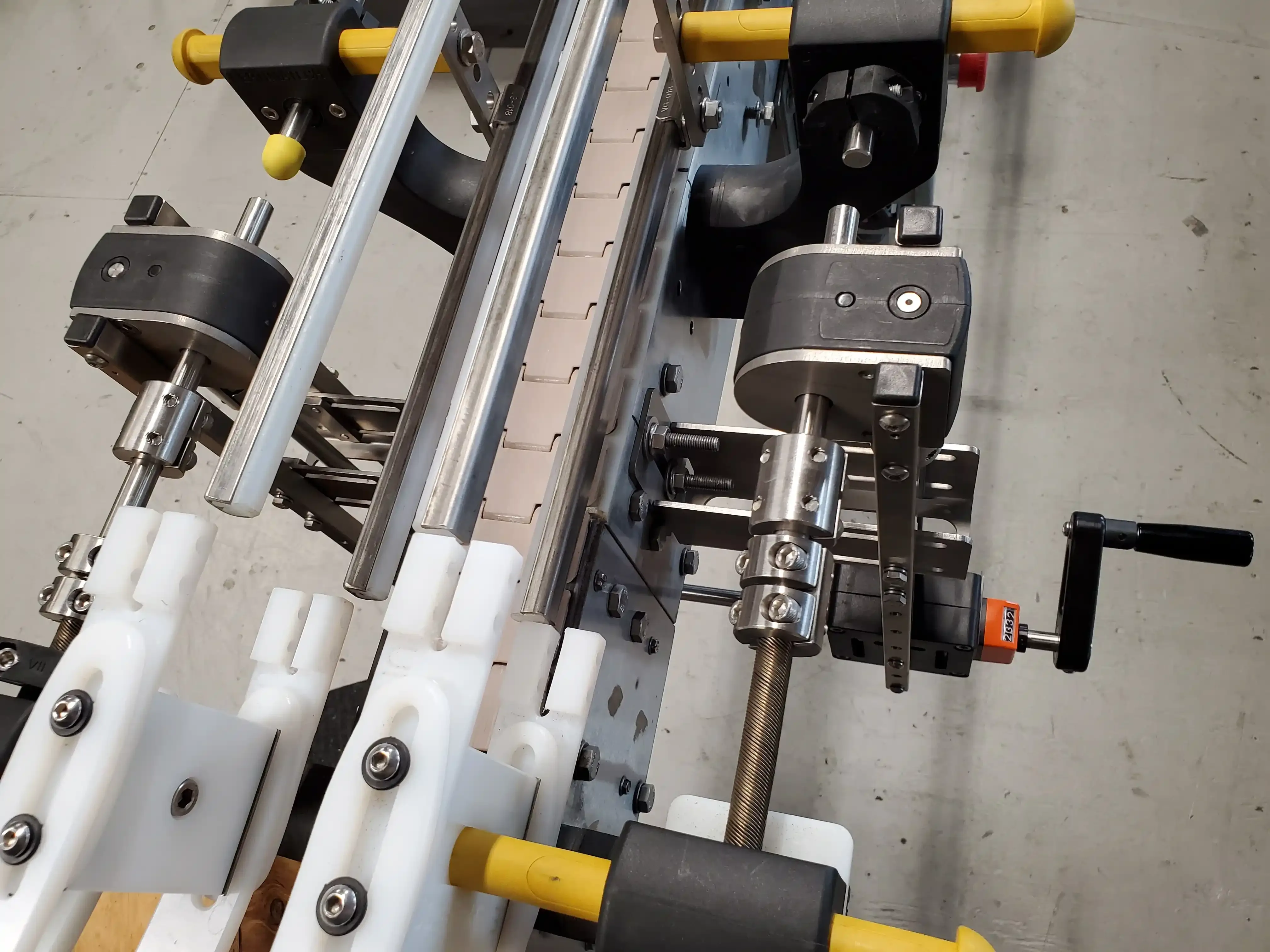

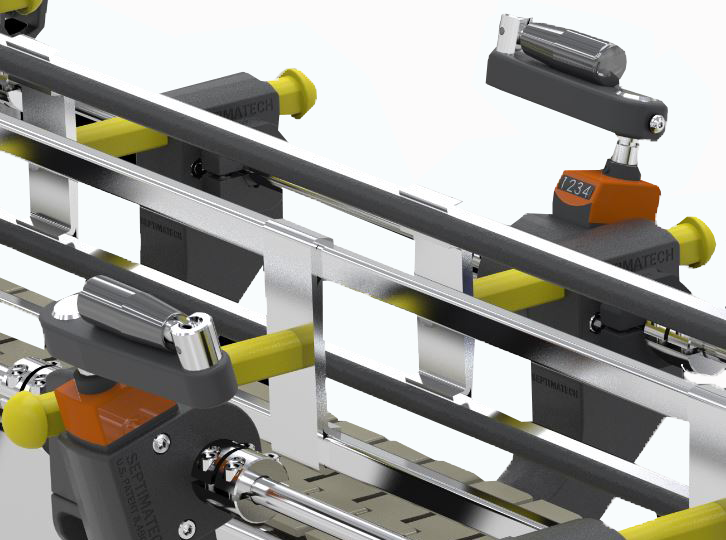

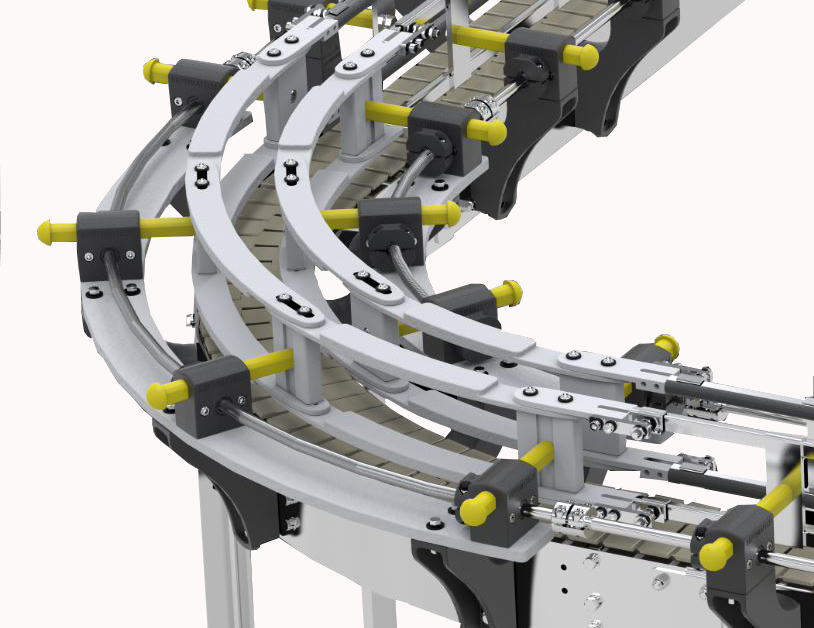

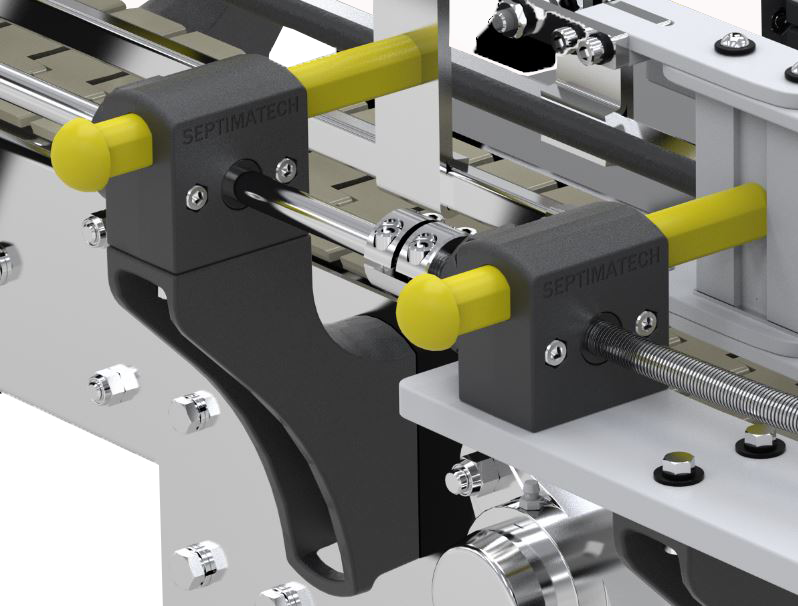

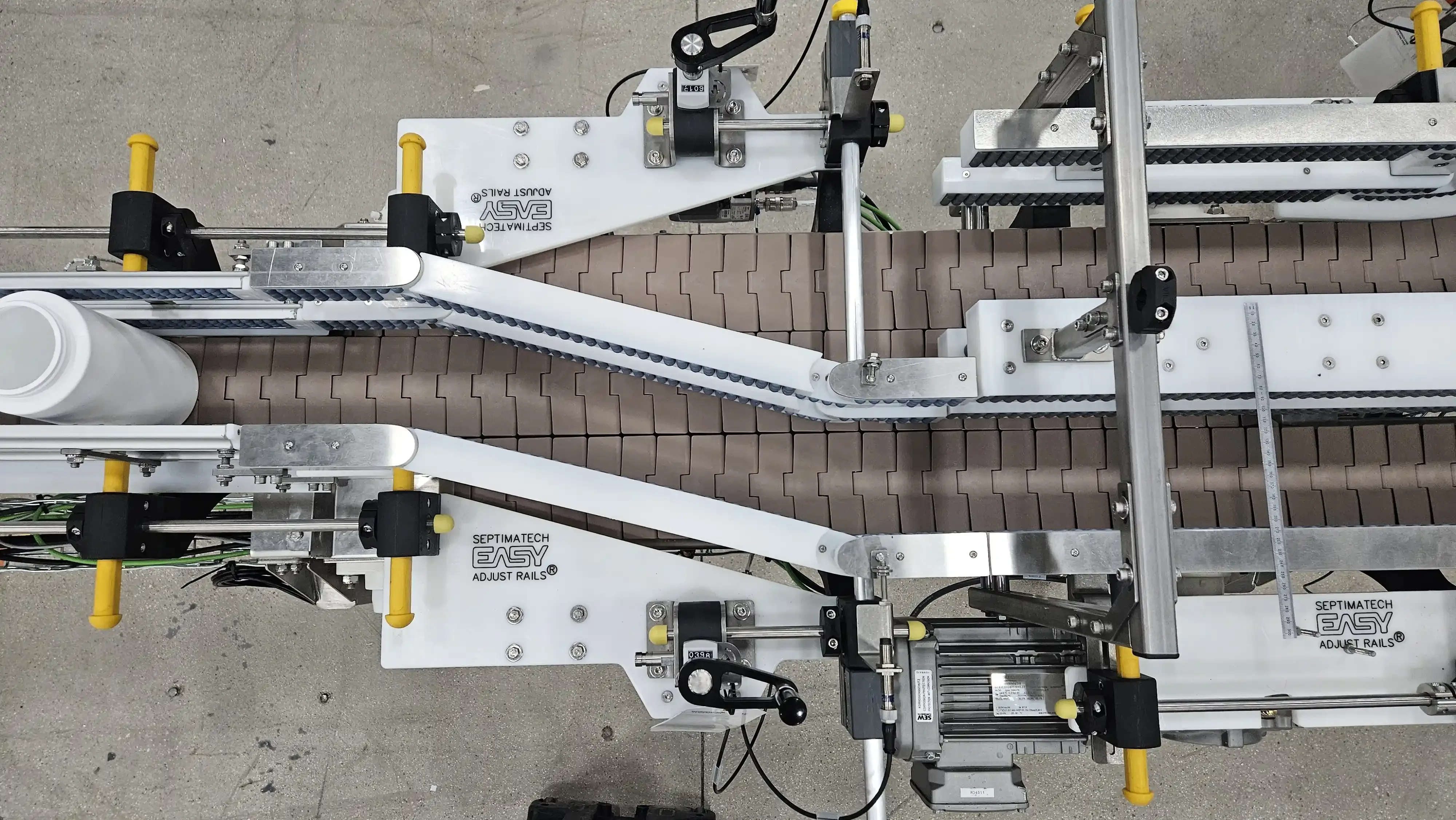

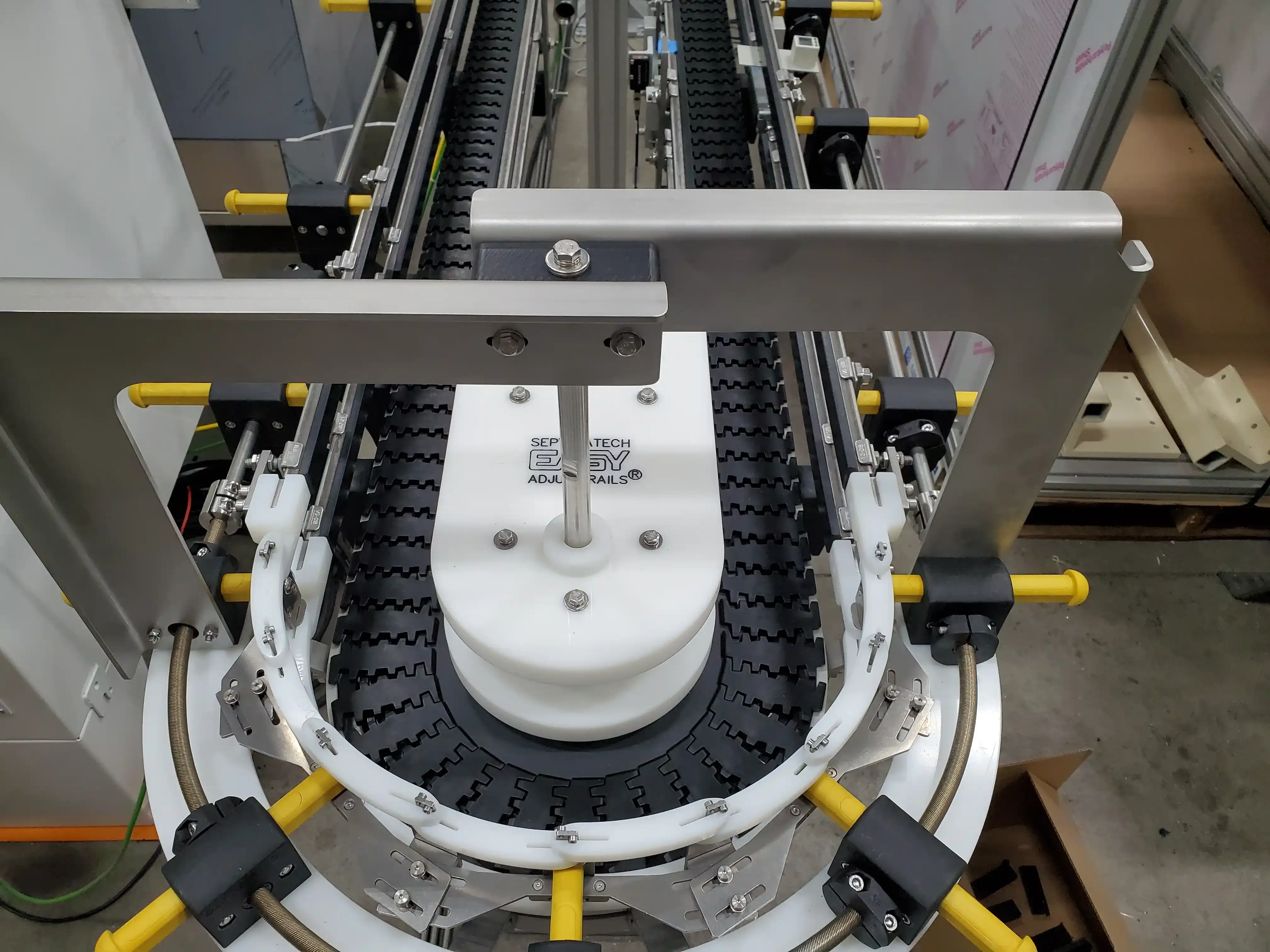

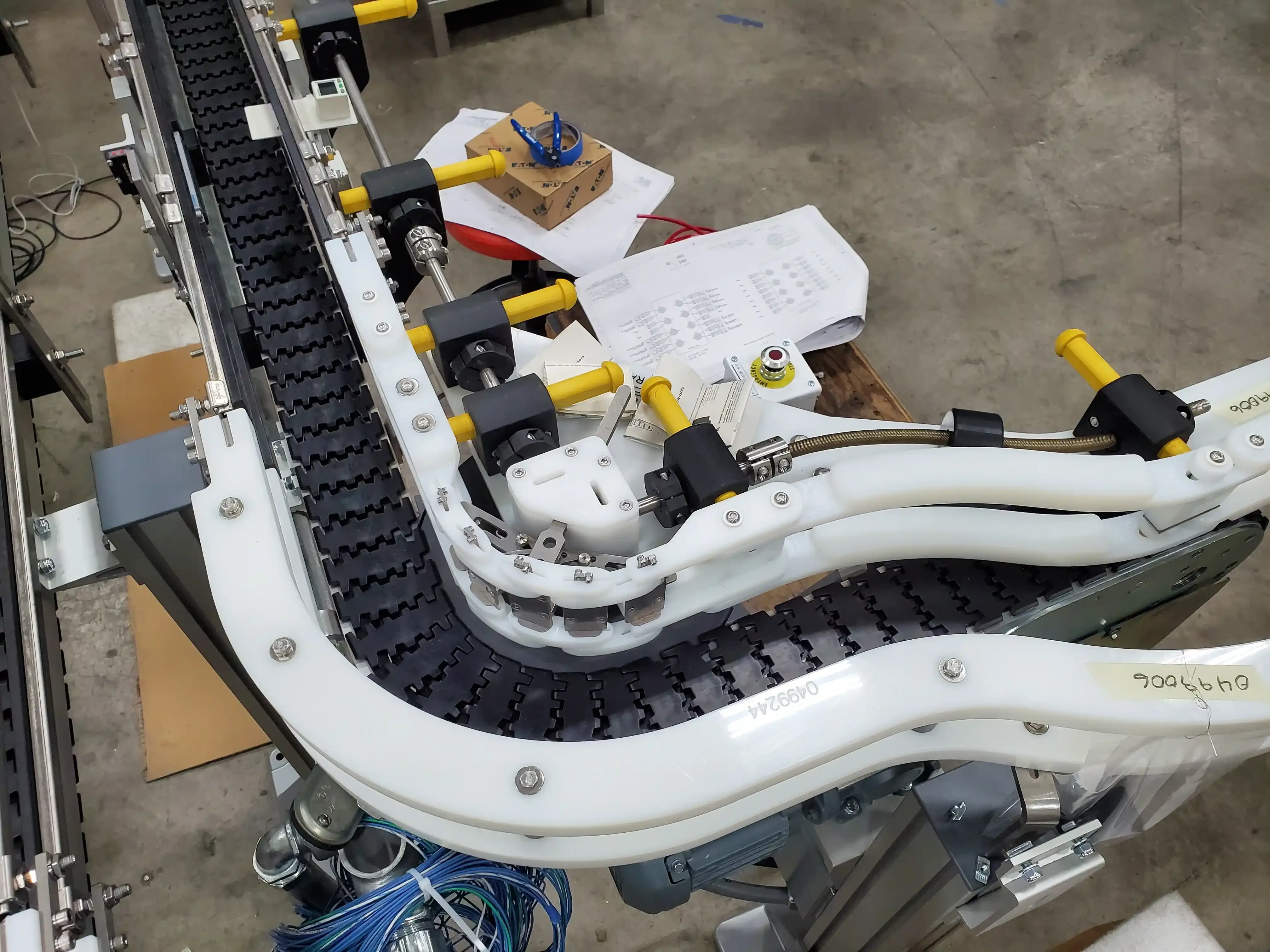

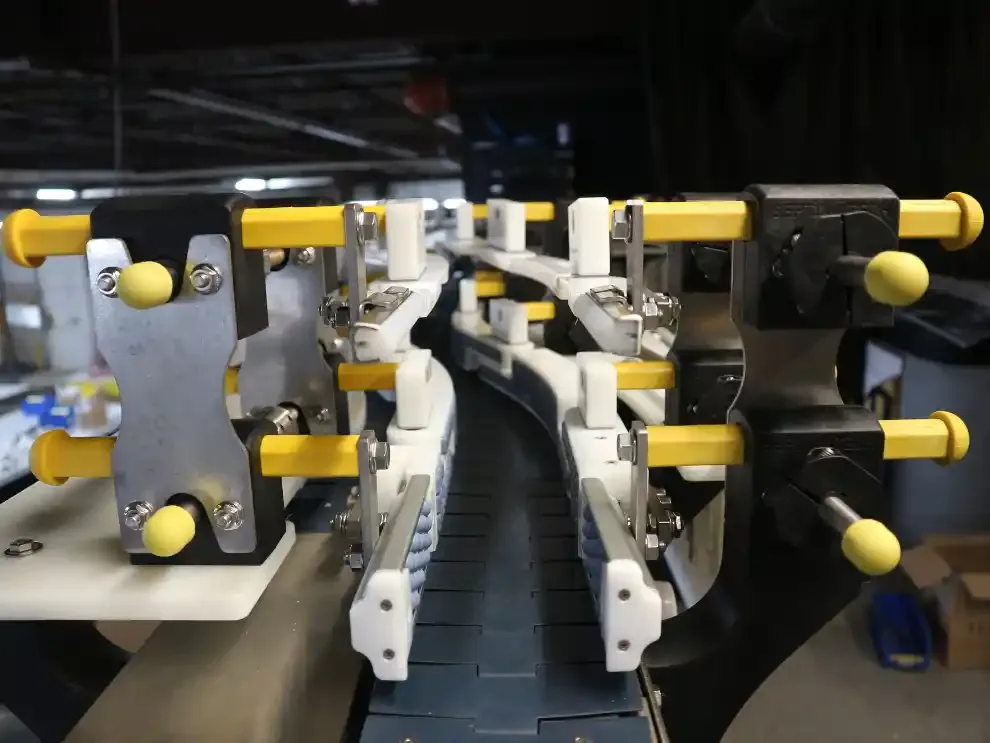

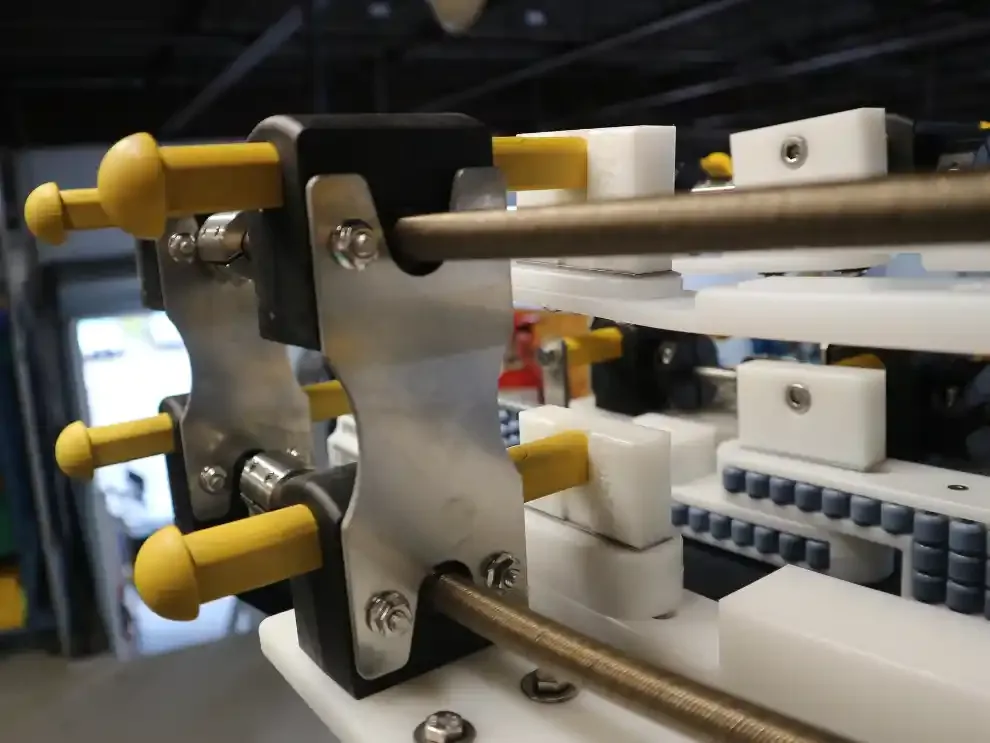

Easy Adjust Guide Rails®

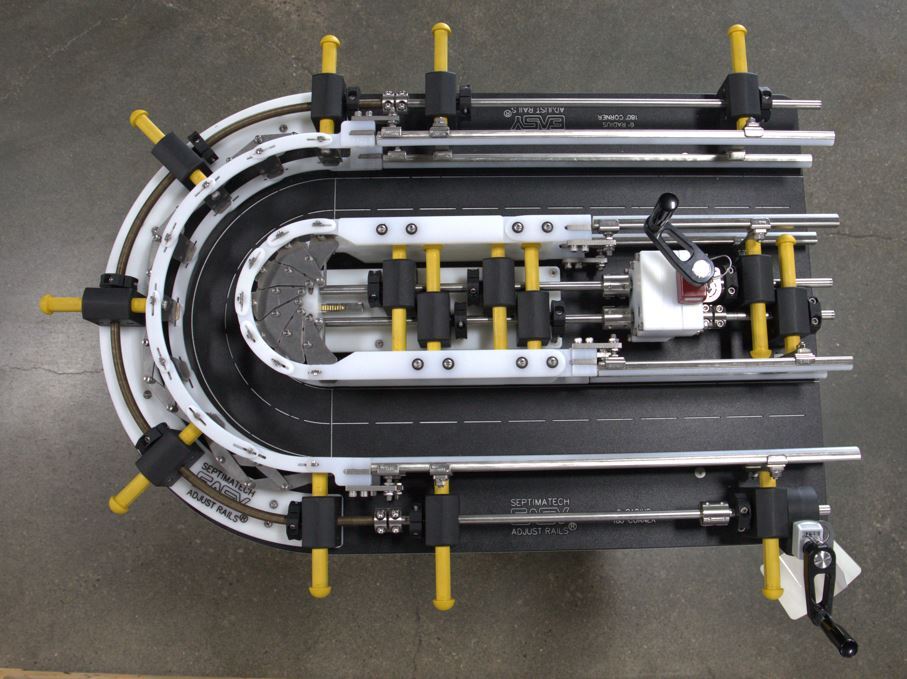

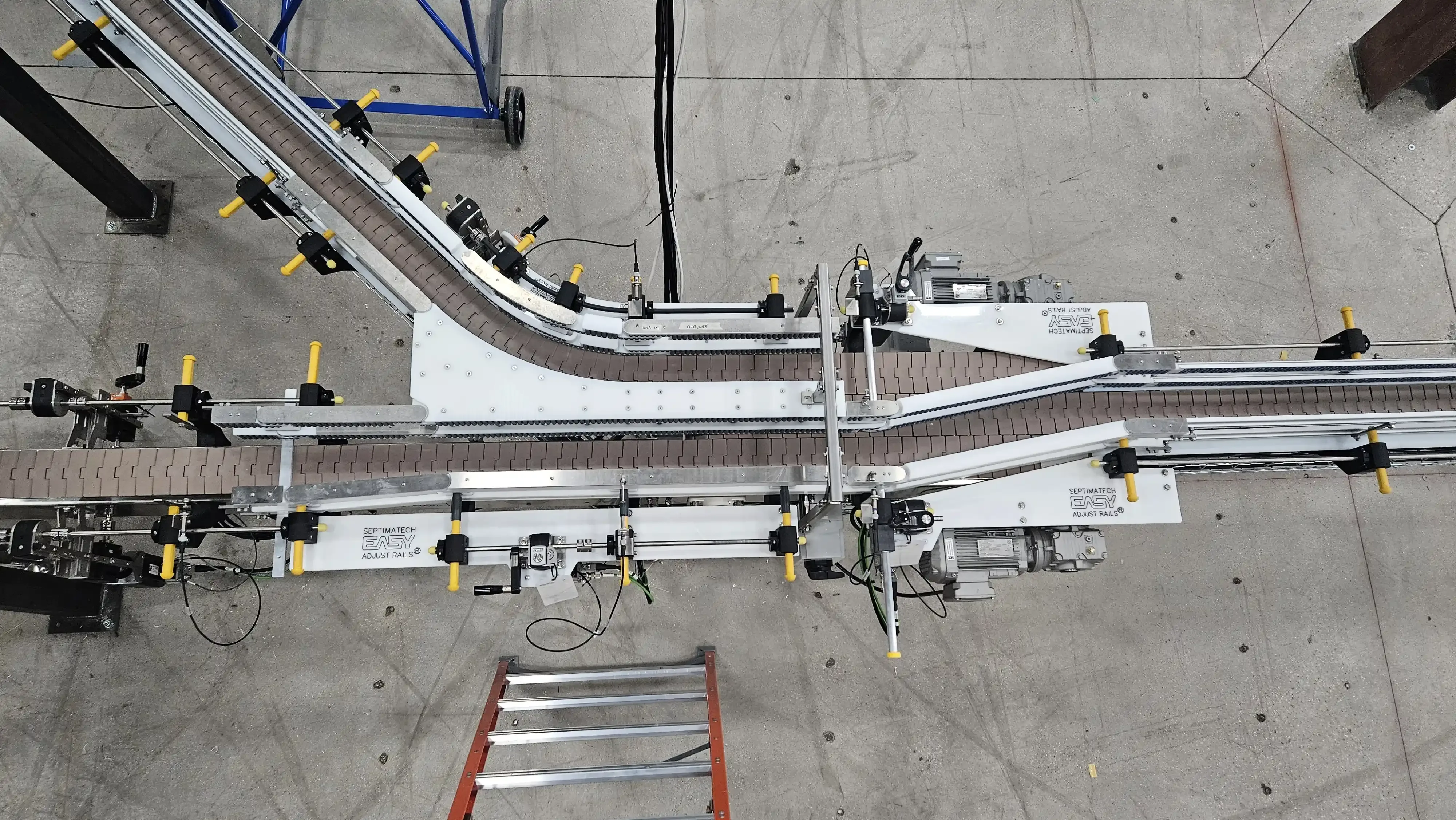

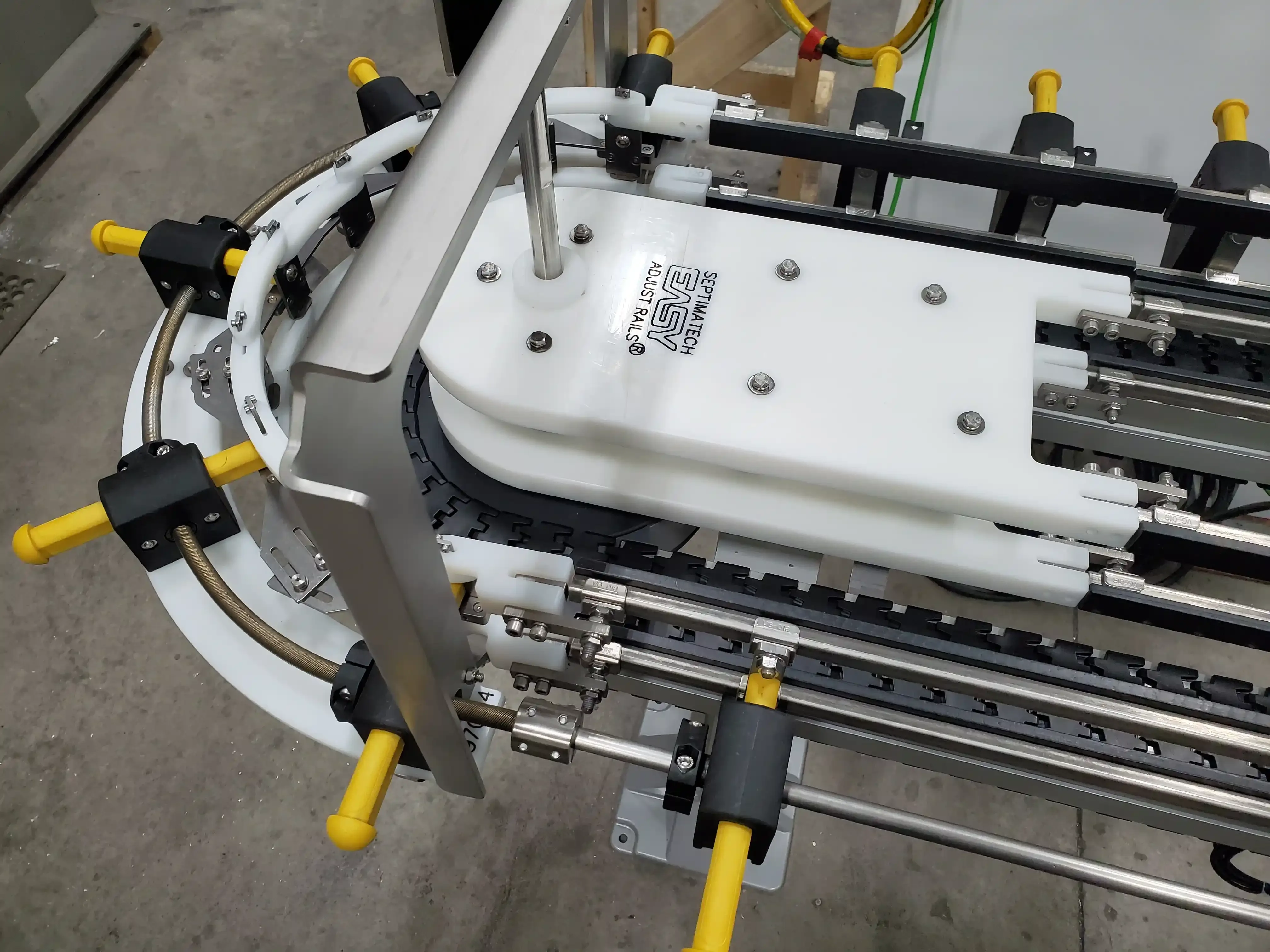

Easily adjust up to 80 feet of guide rail through corners and straights from one location in seconds.

Easy Adjust Rails® are a low cost – high value, economical solution with a quick ROI and a low Total Cost of Ownership.

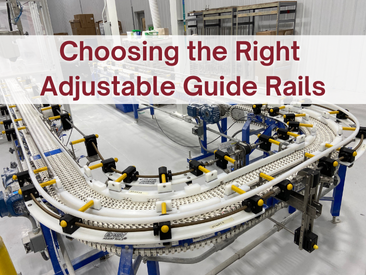

Adjustable conveyor guide rail changeovers are repeatable, fast, and easy. Infinitely adjust guide rails for current and future product introductions.

Our Service Technicians will install Easy Adjust Rails® on your new or existing conveyor to improve changeover efficiency and create greater line flexibility.

- Affordable low capital investment, less than one-year ROI (based upon average of 3 changeovers per week at 30 minutes per changeover)

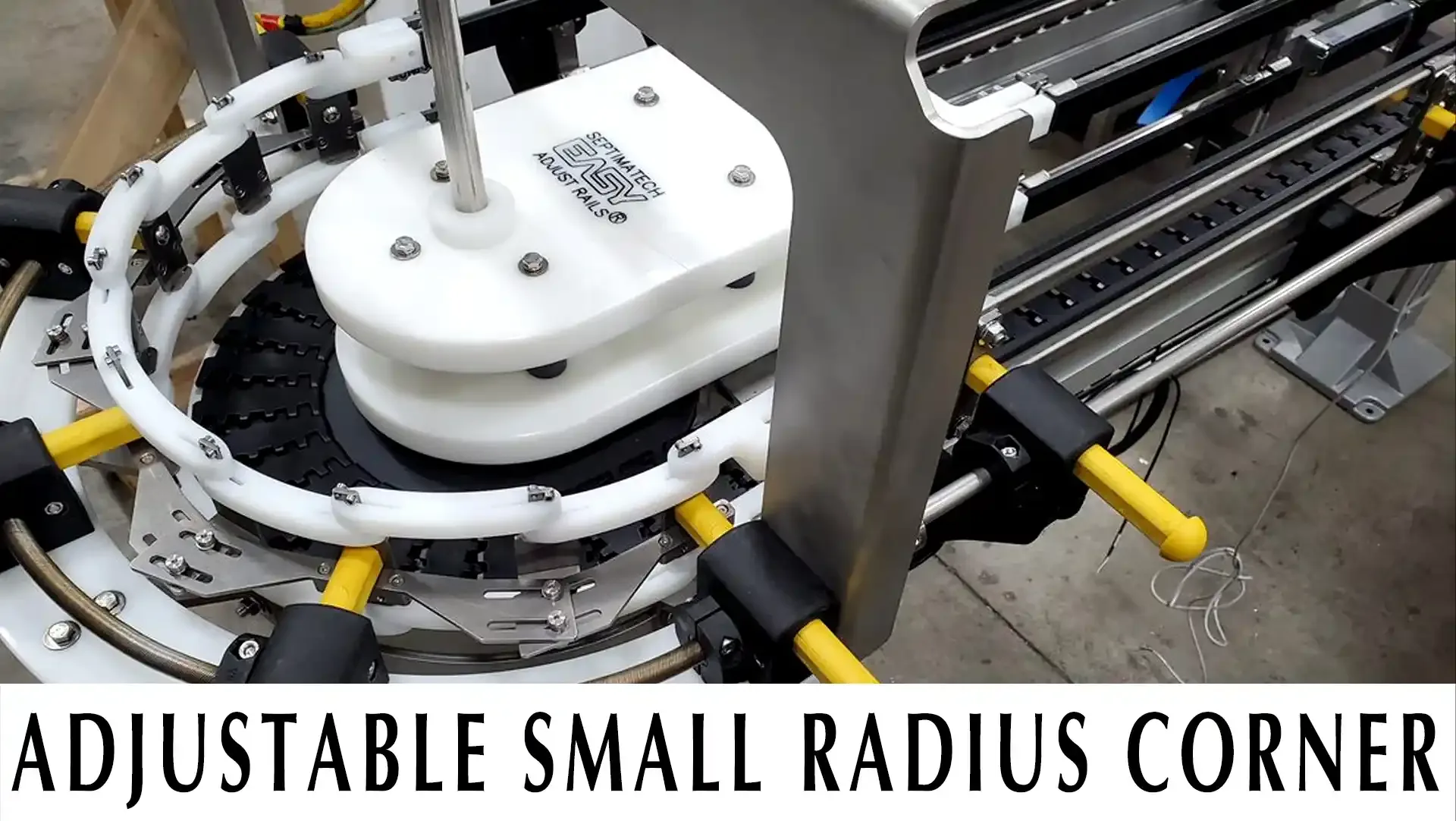

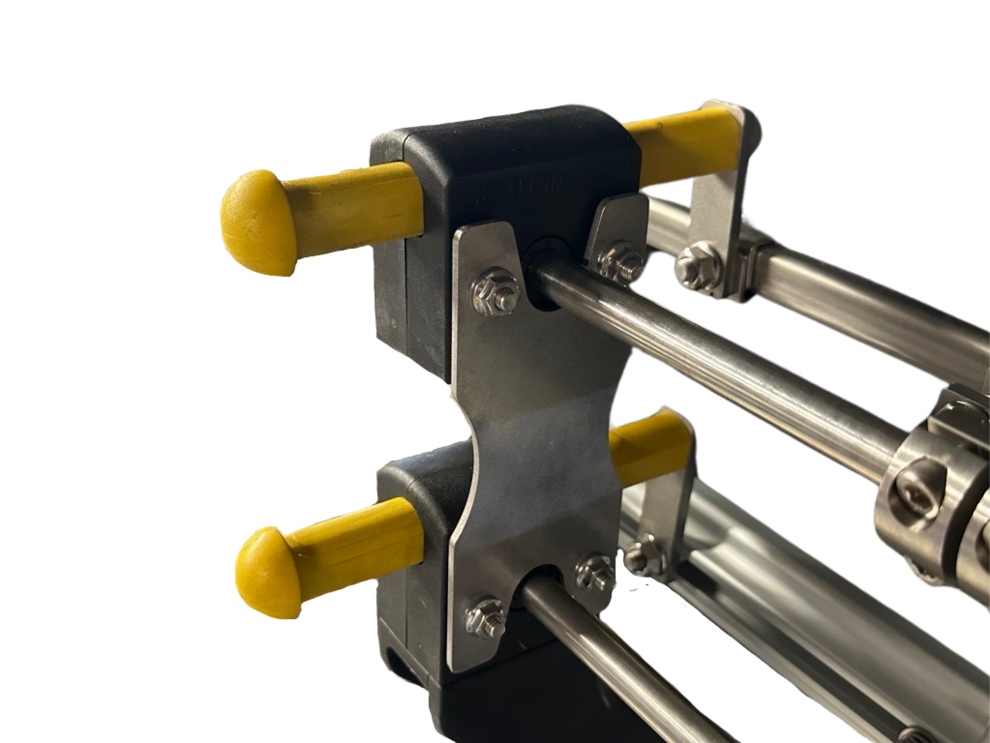

- Repeatable, accurate adjustment – adjust straights and curves accurately to plus or minus 1 mm

- Change over times reduced – adjust up to 80 feet of guide rail, including curves, crossovers and straight sections, from one location by 2” in 10 seconds

- Economical – Low cost high value solution

- Sustainable – No compressed air resources

- Maintenance free – No seals, springs, wires or supply lines subject to wear, damage or leakage

- One-time calibration of system – no springs, seals or pressures to be maintained

- Small foot print, light weight, and rigid – adapts to wheel bend curves, small to large size conveyor configuration, durable to handle boxes or any size container

- Retrofit existing conveyor – engineered to retrofit to any existing or new conveyor systems, interchangeable when line configuration needs to change

Additional Adjustable Guide Rail Applications & Solutions

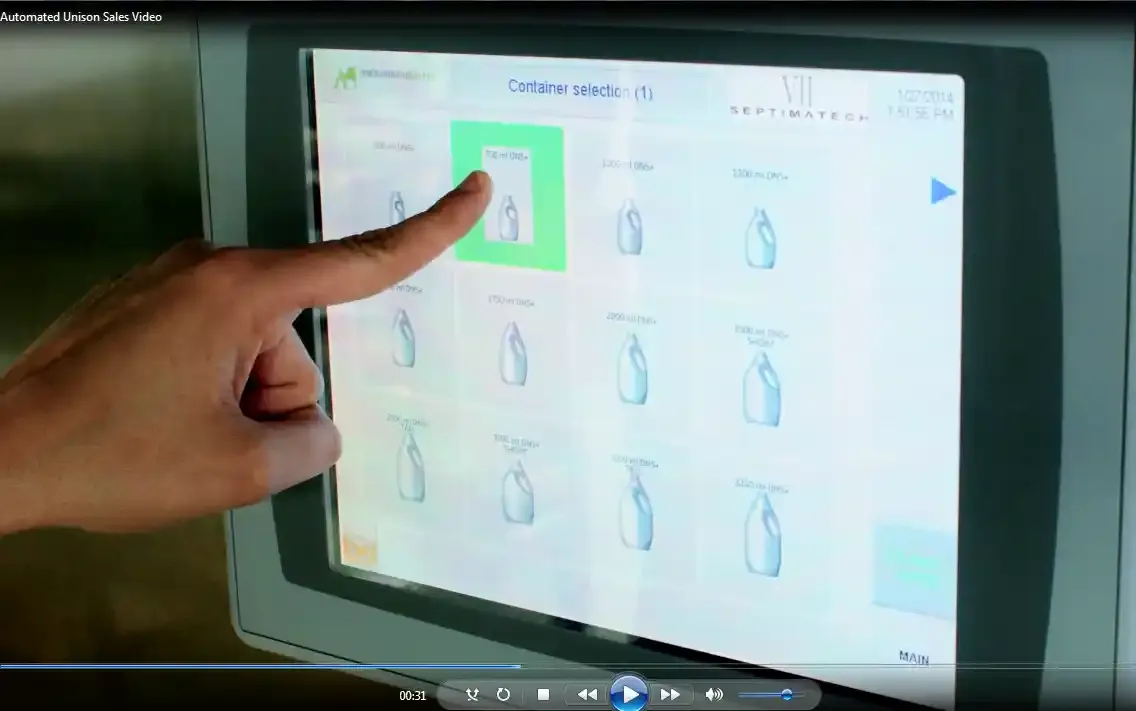

Easy Adjust Guide Rail System® is ideal for repeatable efficient changeovers on air conveyors.

The Easy Adjust Guide Rail System® can be applied to any air conveyor configuration; straight, corner, or curve sections can be adjusted to the various container neck and body size profiles from the ground floor.

This eliminates the need for lifting equipment, which alleviates health and safety elevation concerns, and provides a solution for difficult to reach areas.

If you need to prevent dust particle contamination during the transport of containers on your packaging line then the Easy Adjust Guide Rail® Dust Cover System can solve the problem.

Dust covers can retrofit to any conveyor configuration and type.

Whether containers are short or tall in profile the flexibility of the Easy Adjust Guide Rail® Dust Cover System is adaptable to suit any production requirement.

Dust covers are available in light weight designs and have flexible adjustment capabilities to adjust vertically to varying heights of containers.

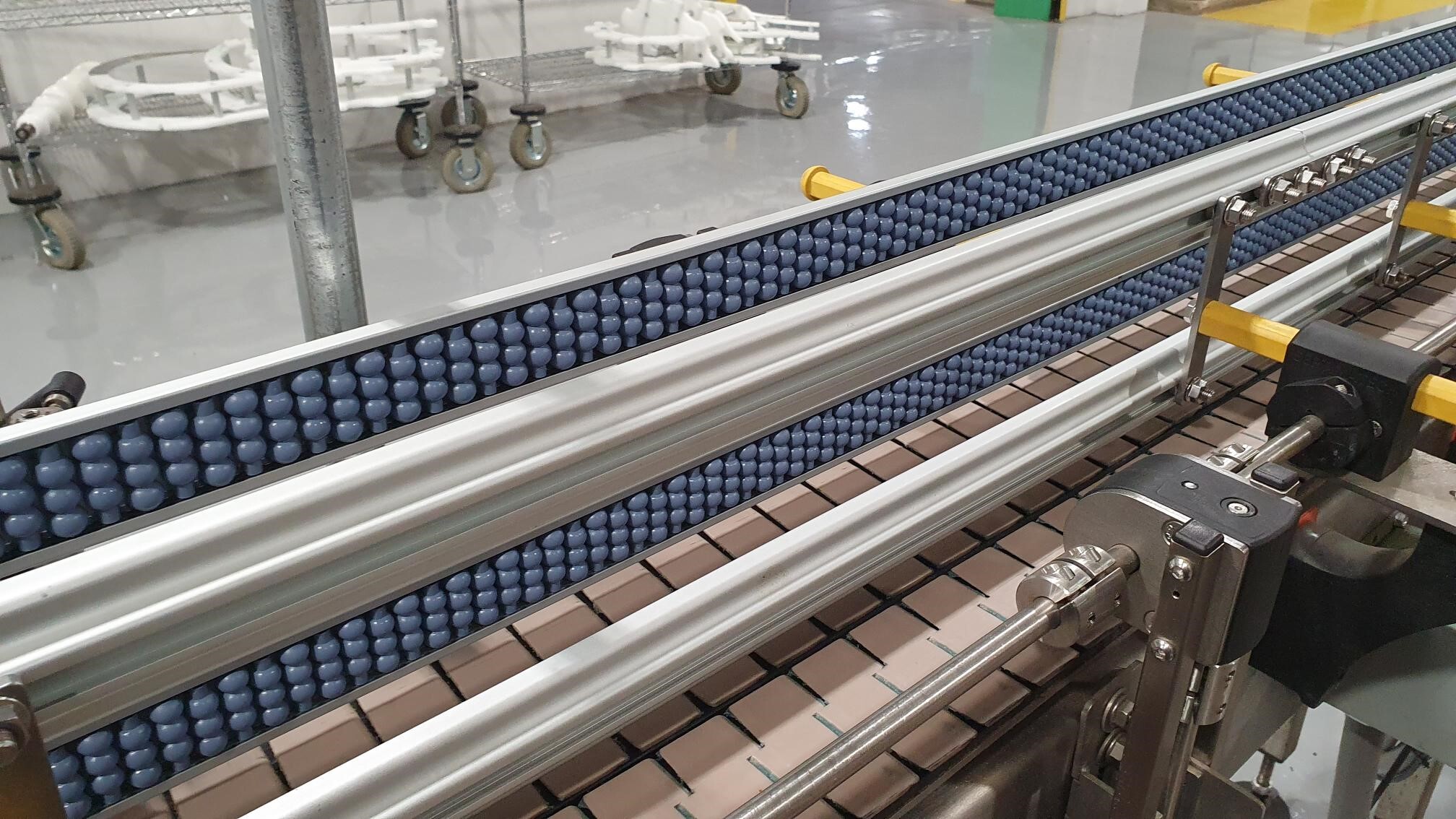

Septimatech's Beaded Guide Rails are a specialized product designed to provide smooth and gentle container handling.

The roller beaded design reduces friction and static, allowing for better control and stability of containers as they move through various stages of production, such as filling, labeling, and capping.

These guide rails are particularly beneficial for delicate or irregularly shaped containers, ensuring consistent performance and reducing the risk of jams, scuffing, or damage during high-speed operations.

Ready for a Quote?

Precision adjustment without tools — request your custom Easy Adjust solution.