-

-

-

-

-

Need a Quote on a Solution?

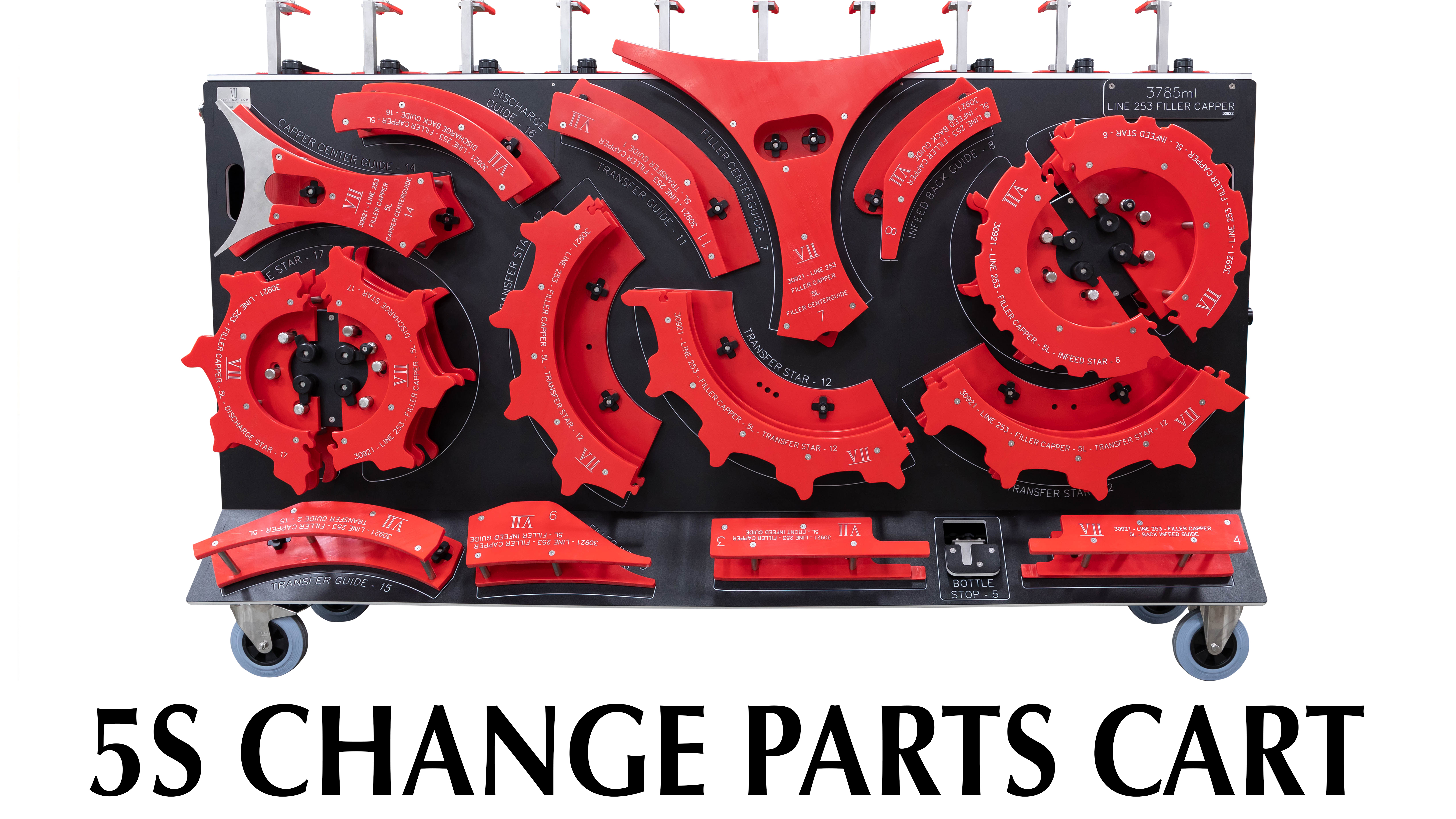

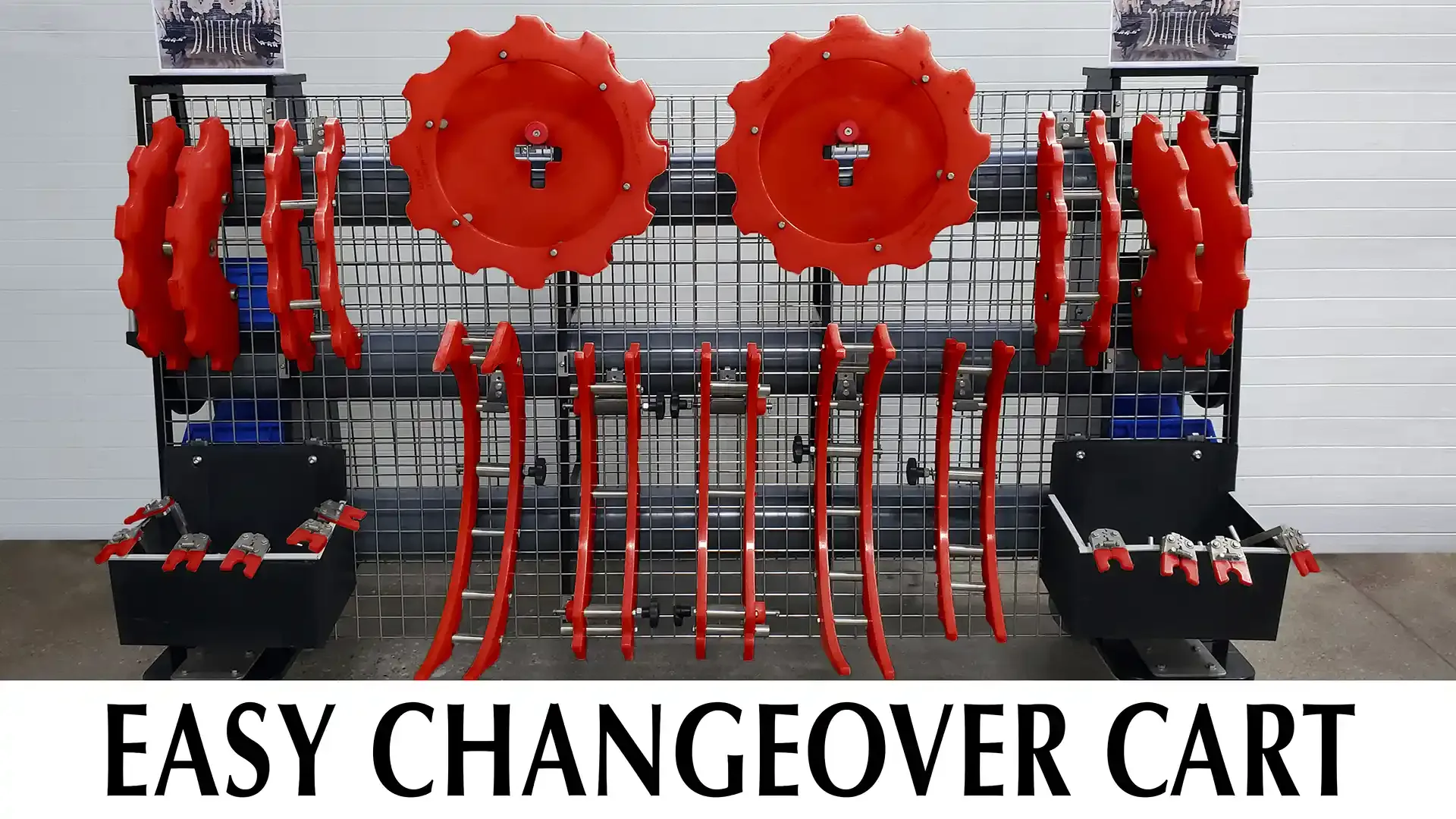

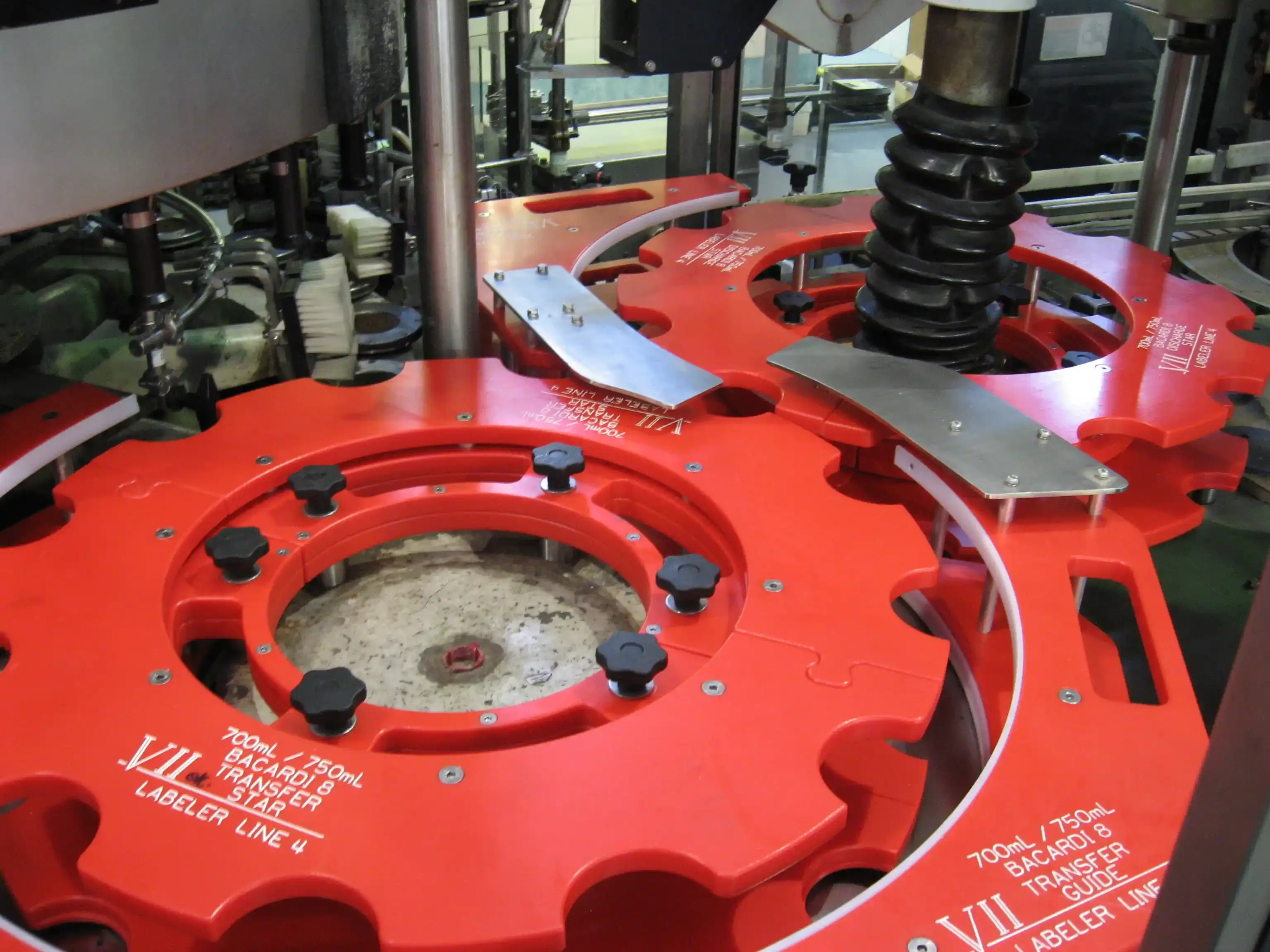

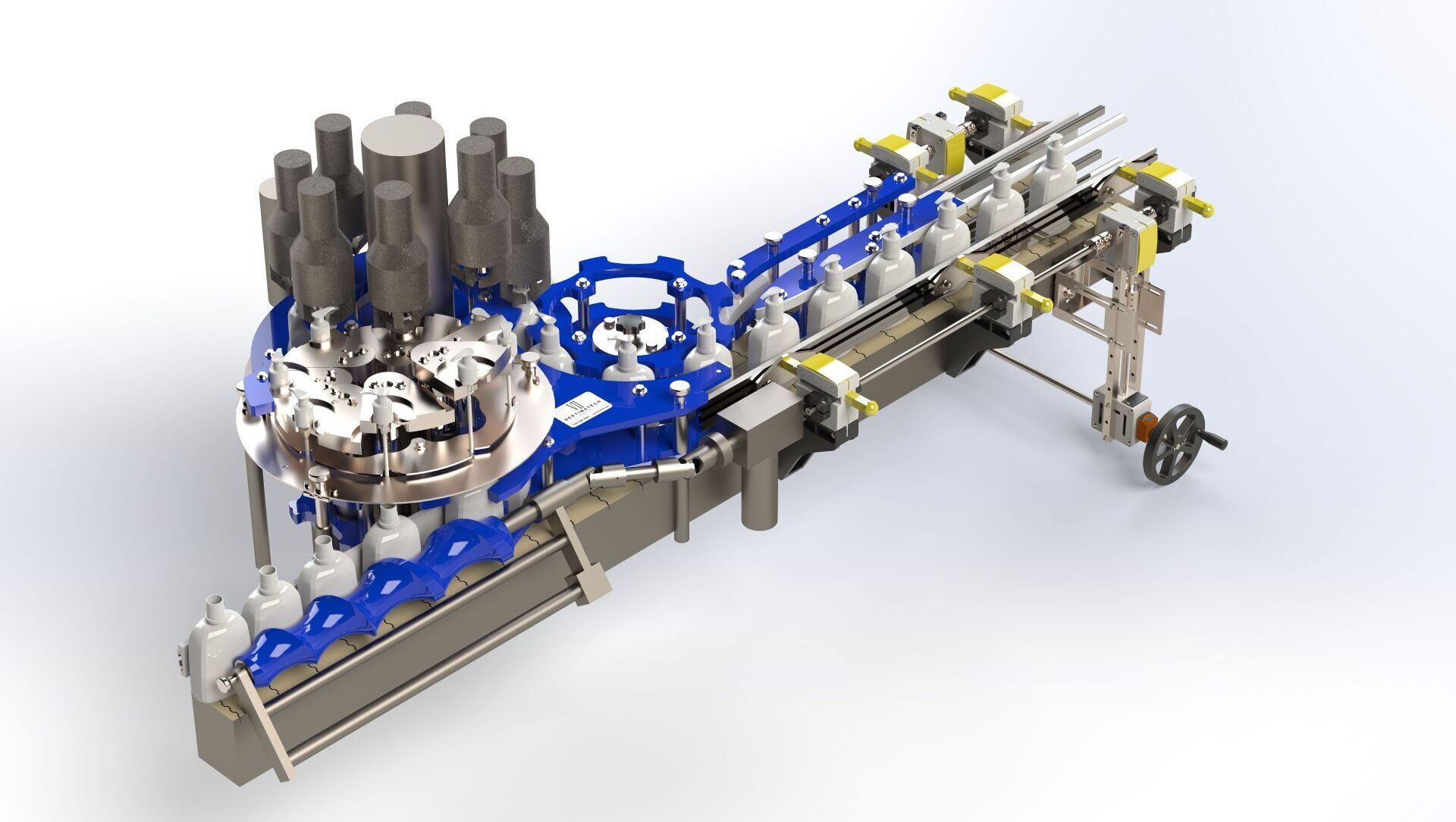

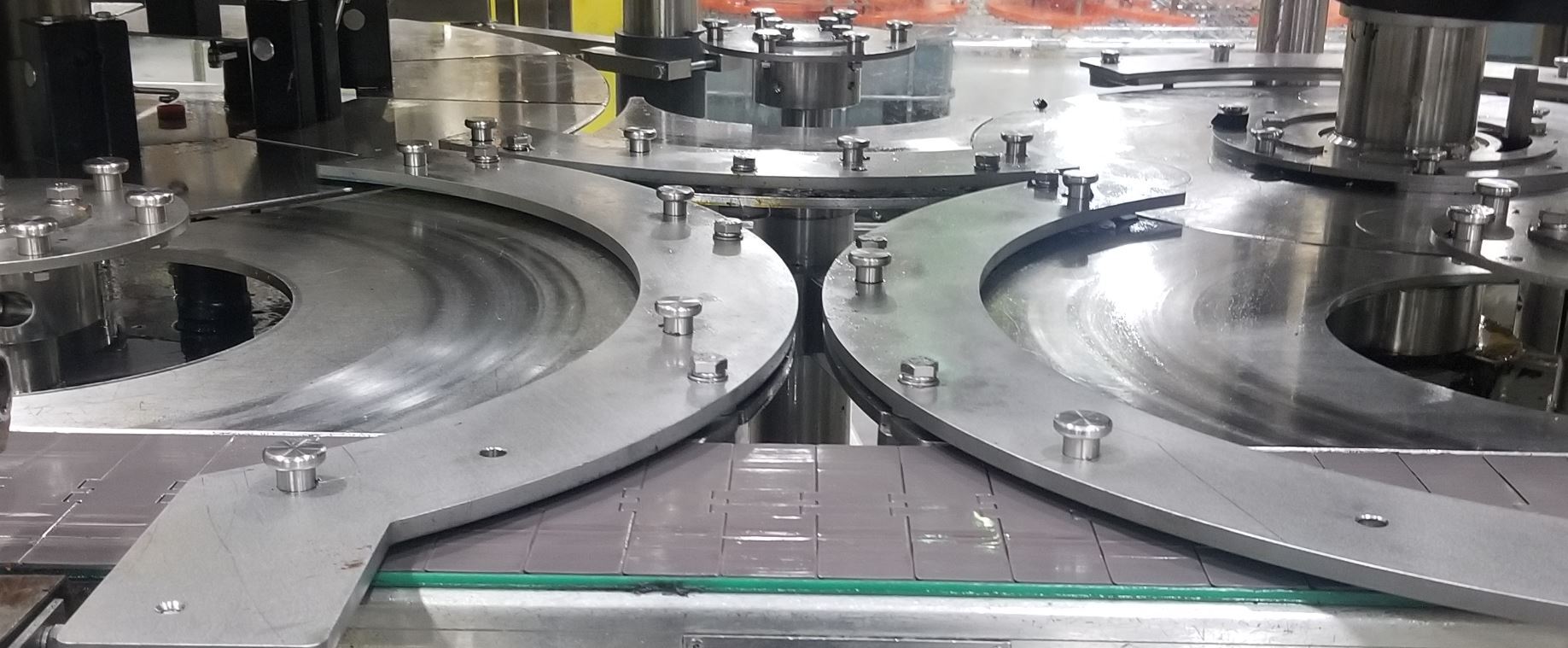

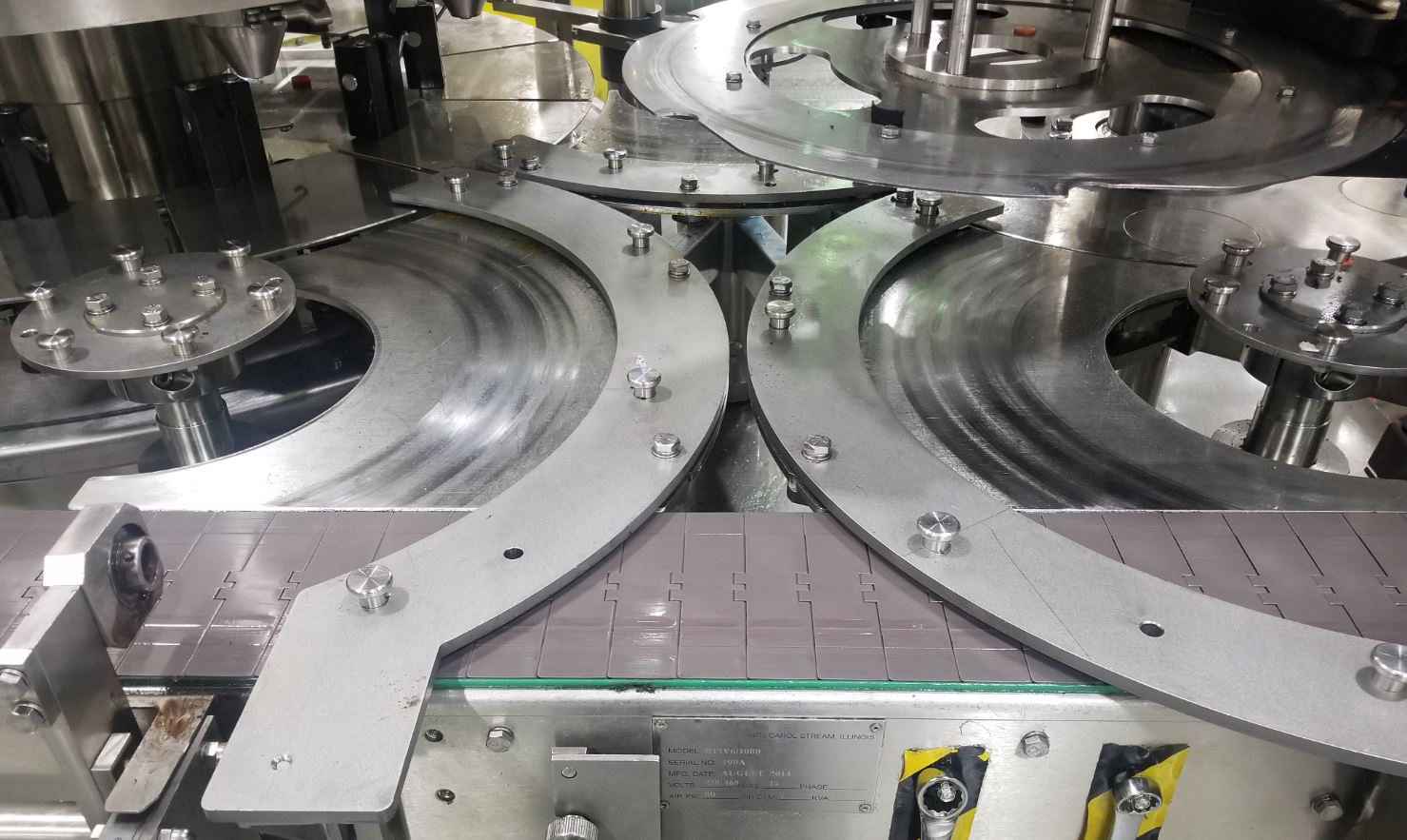

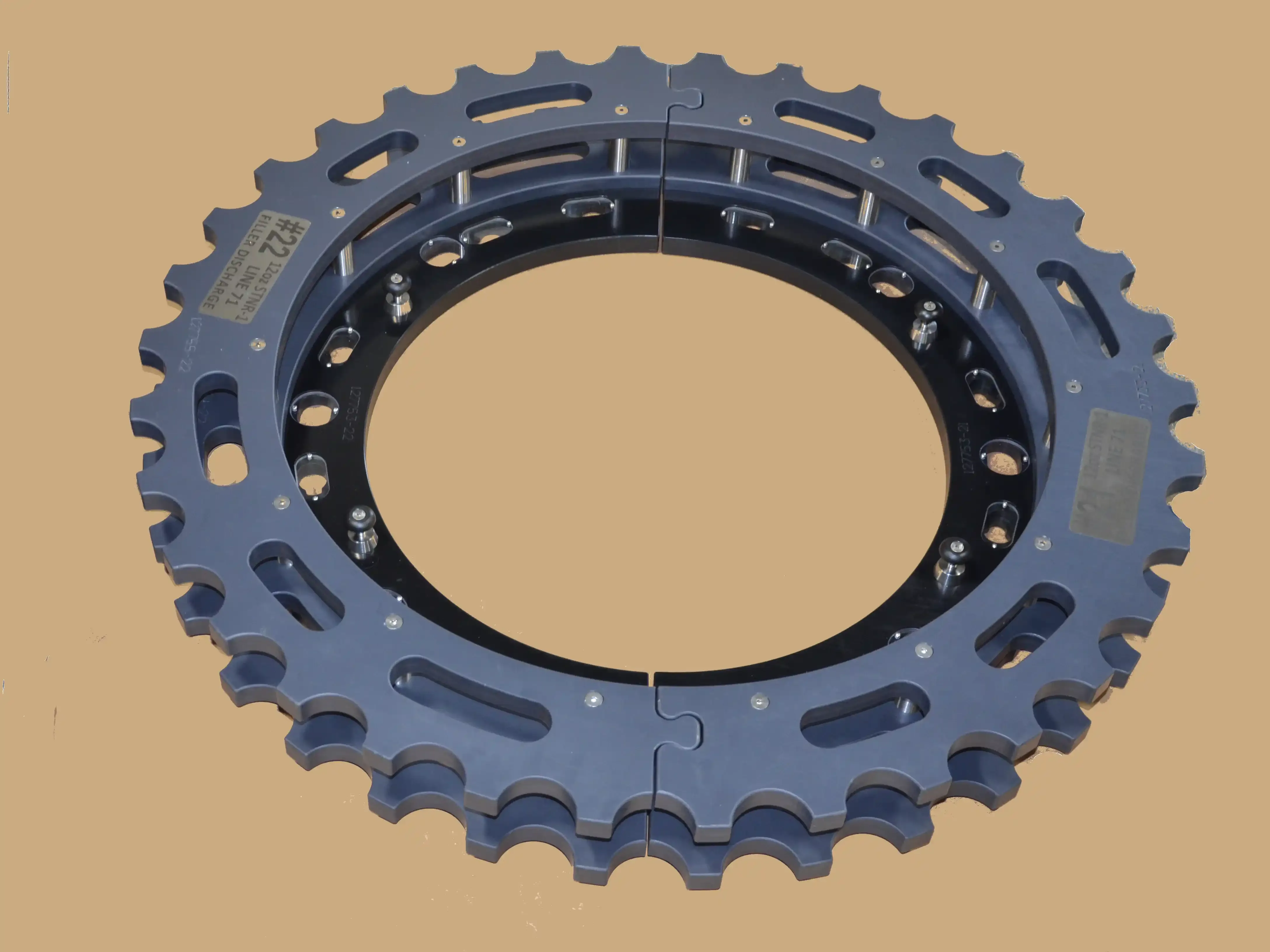

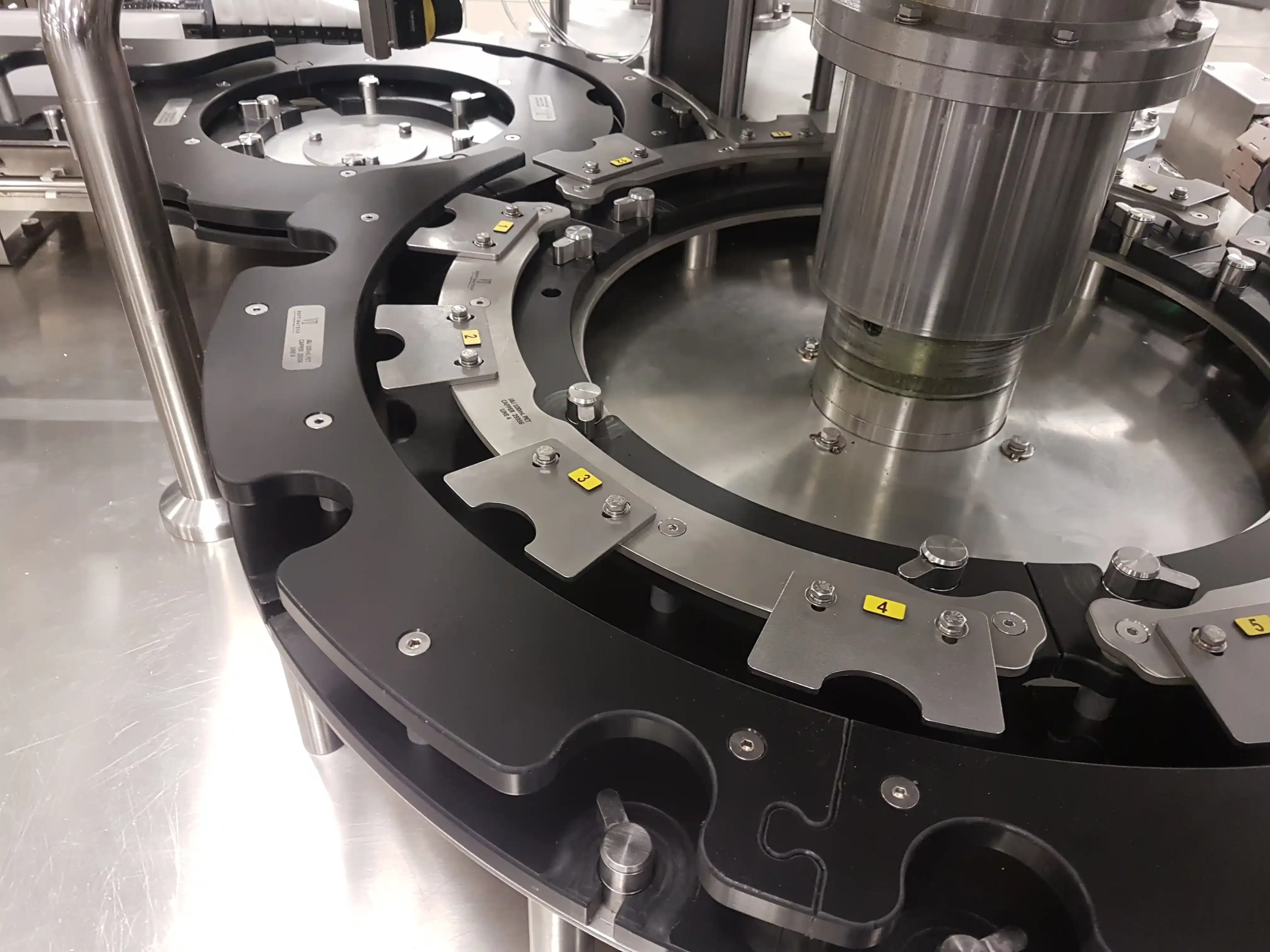

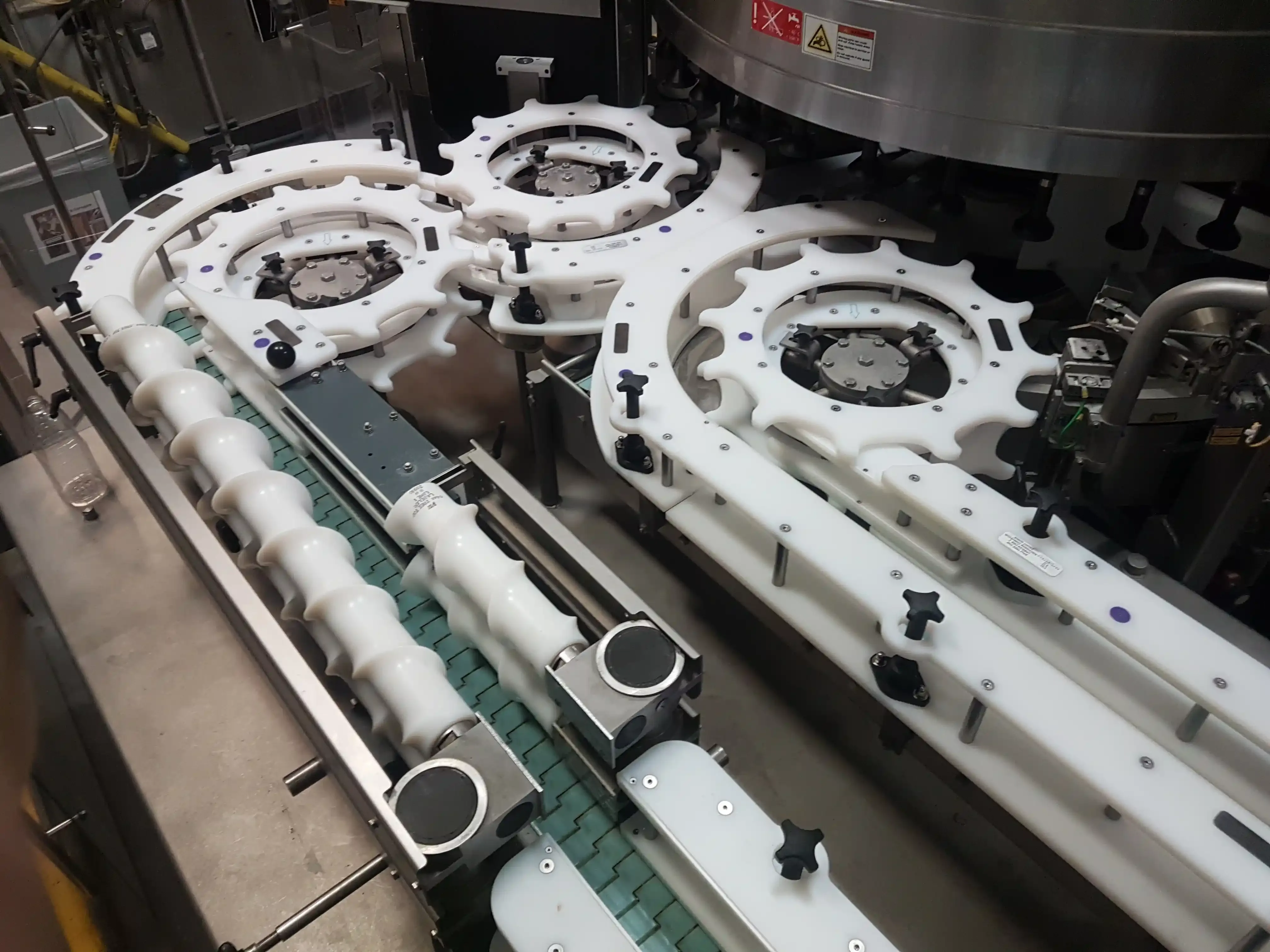

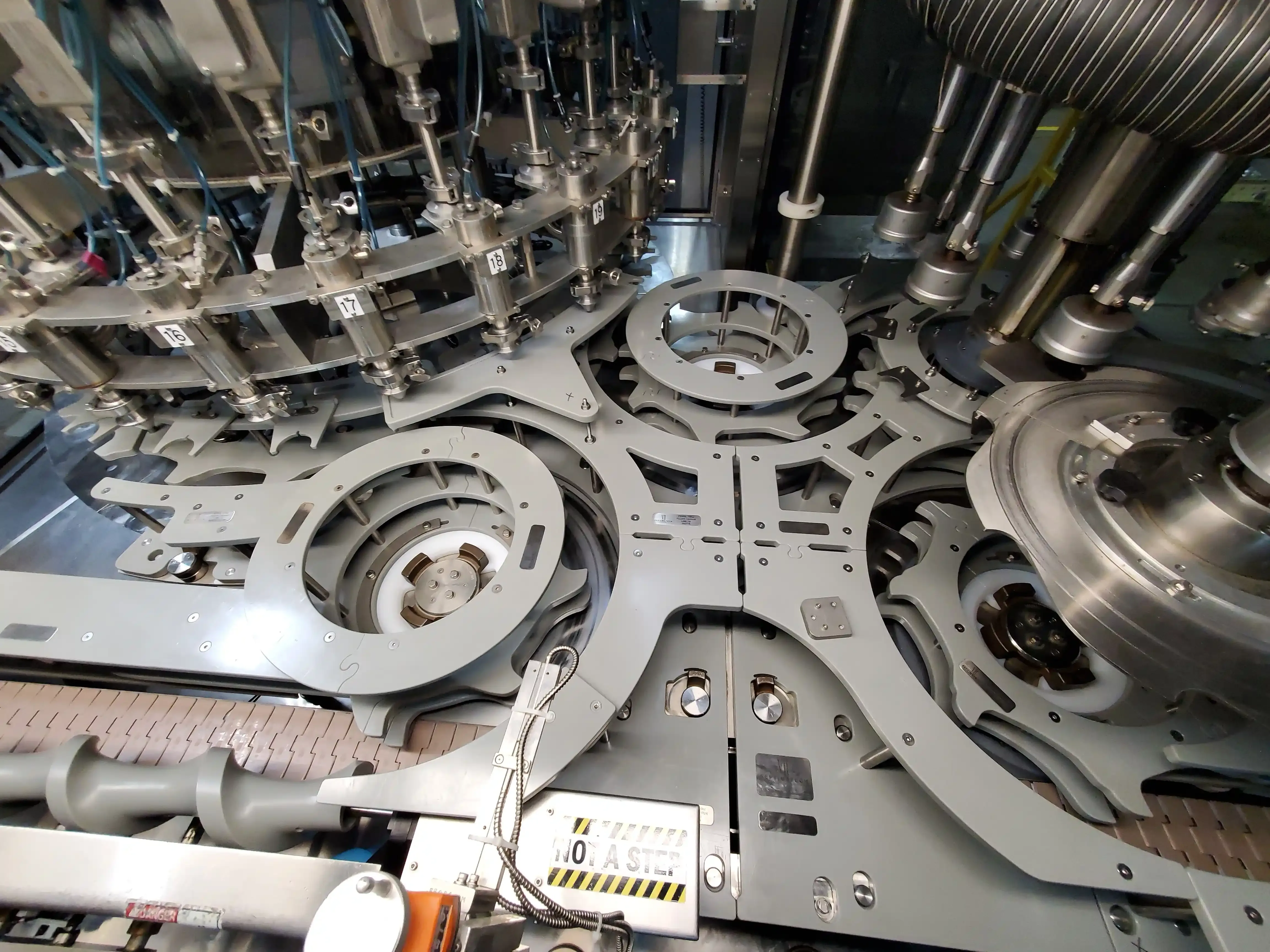

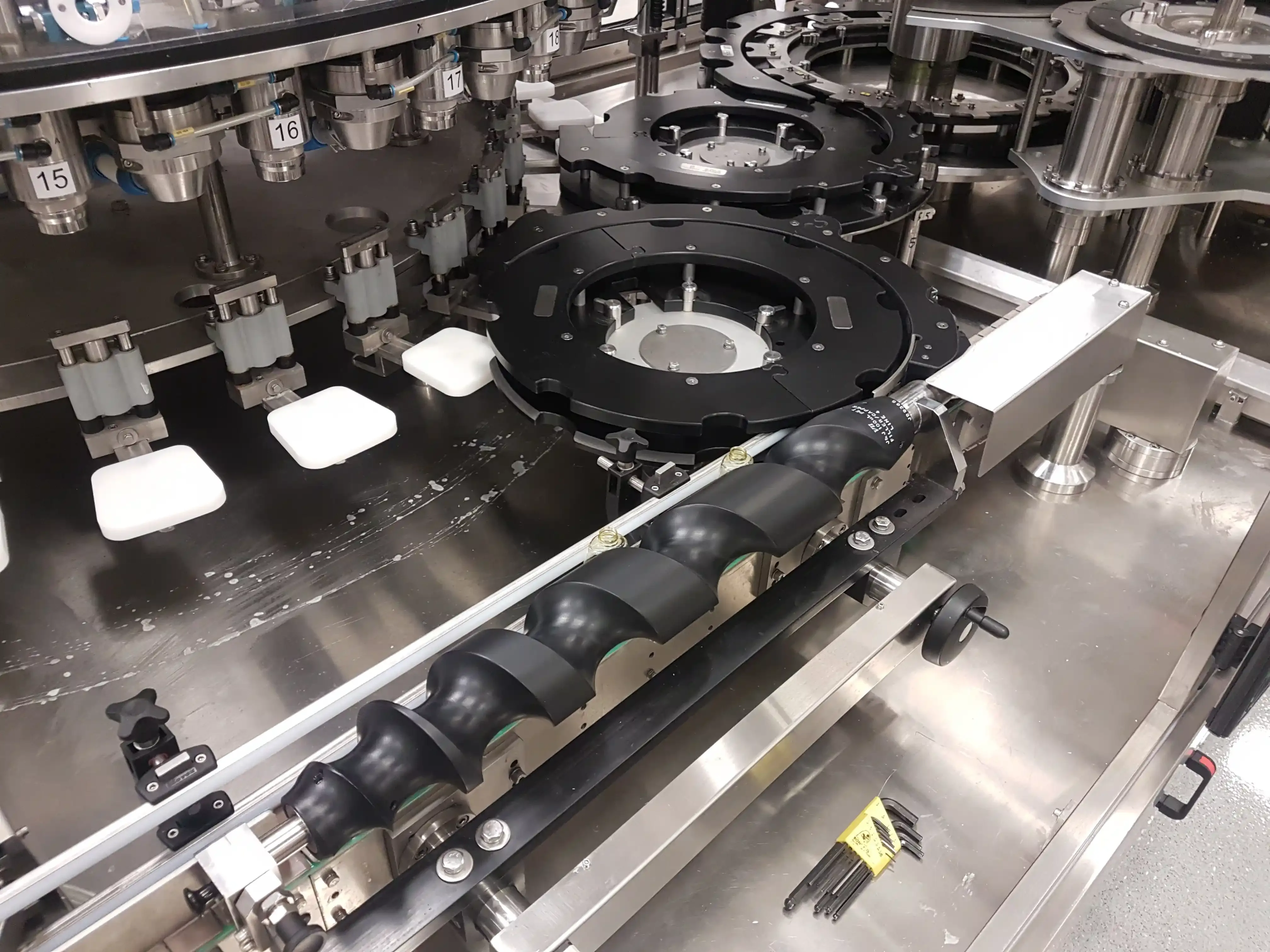

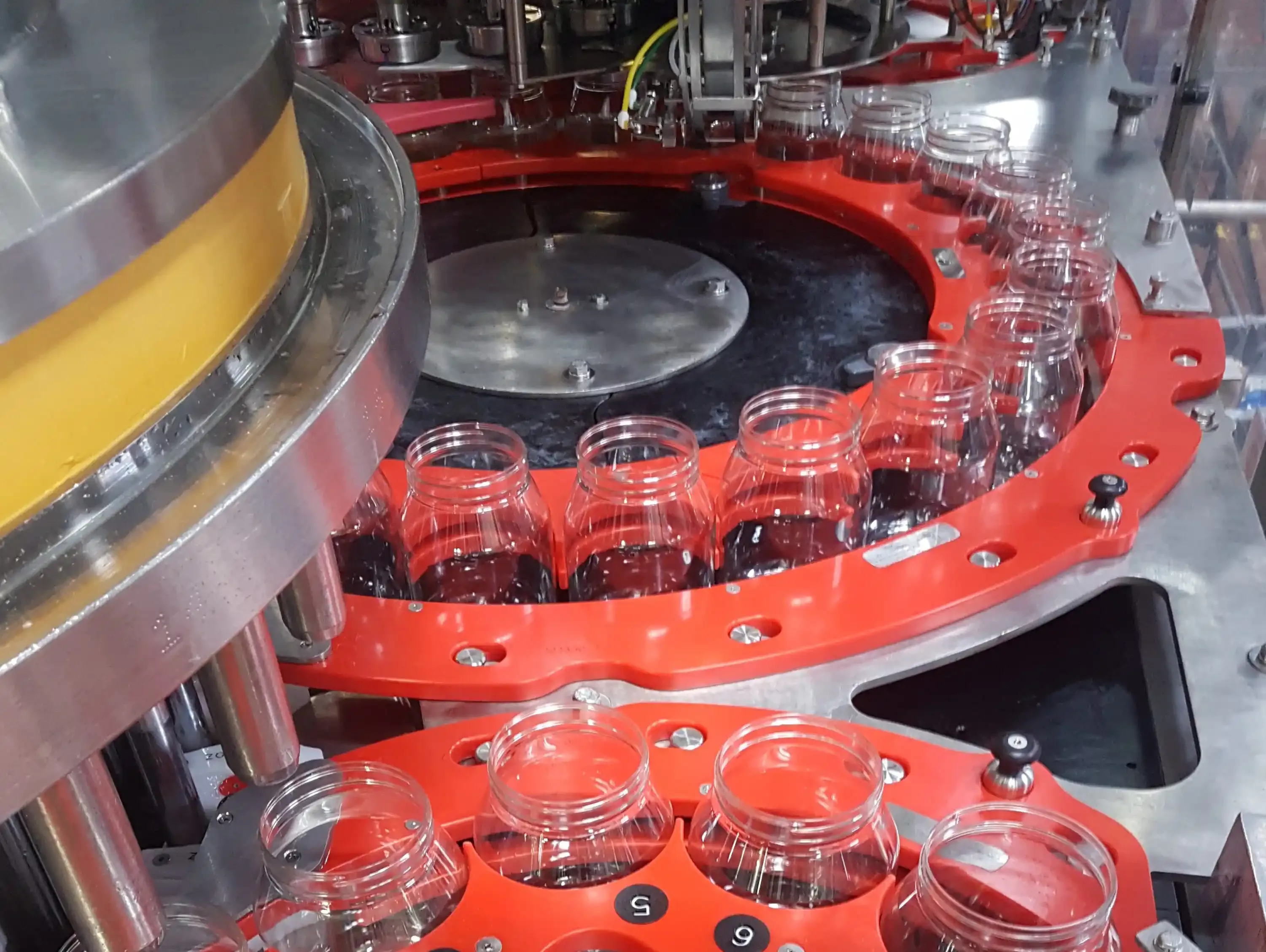

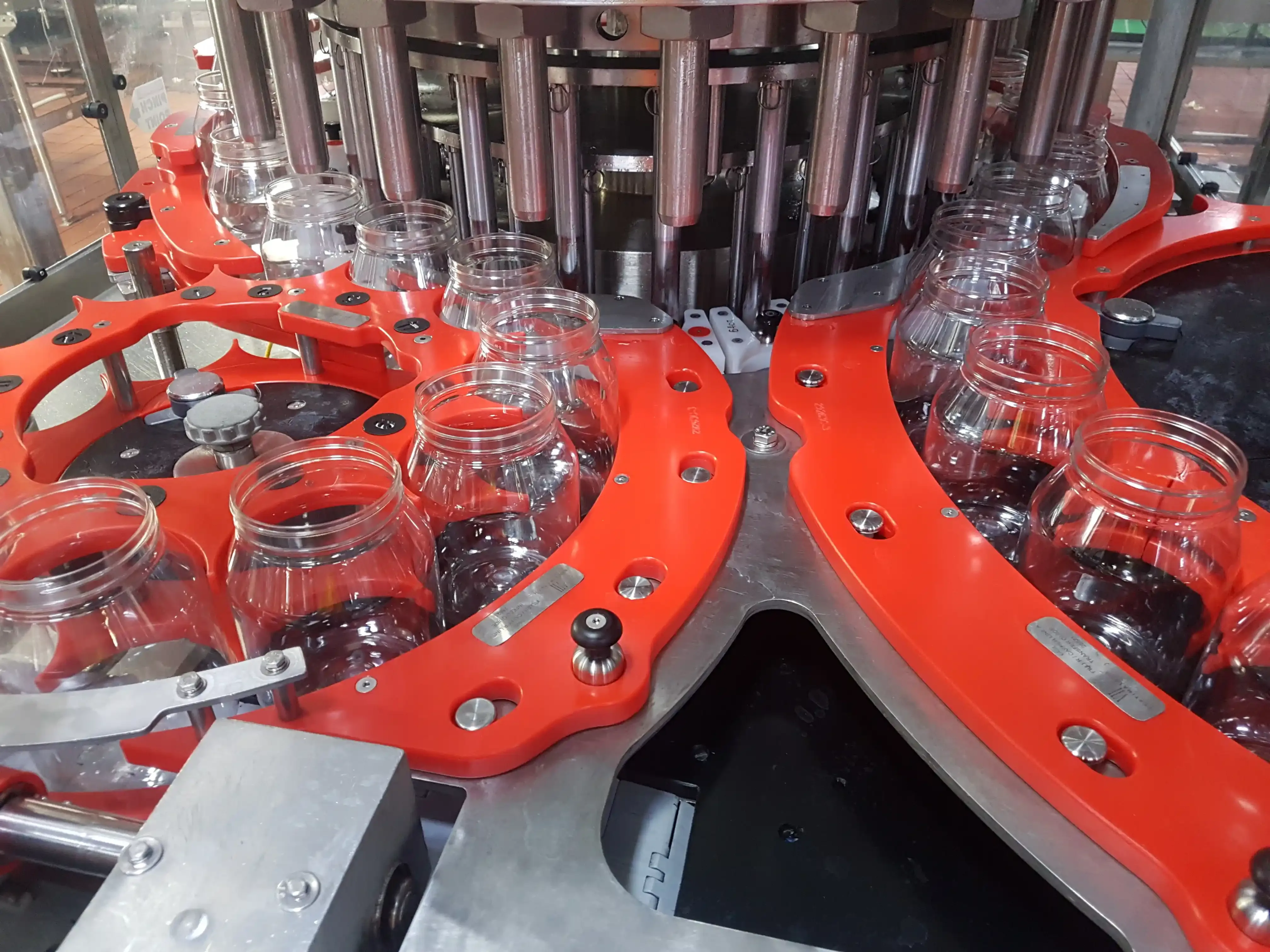

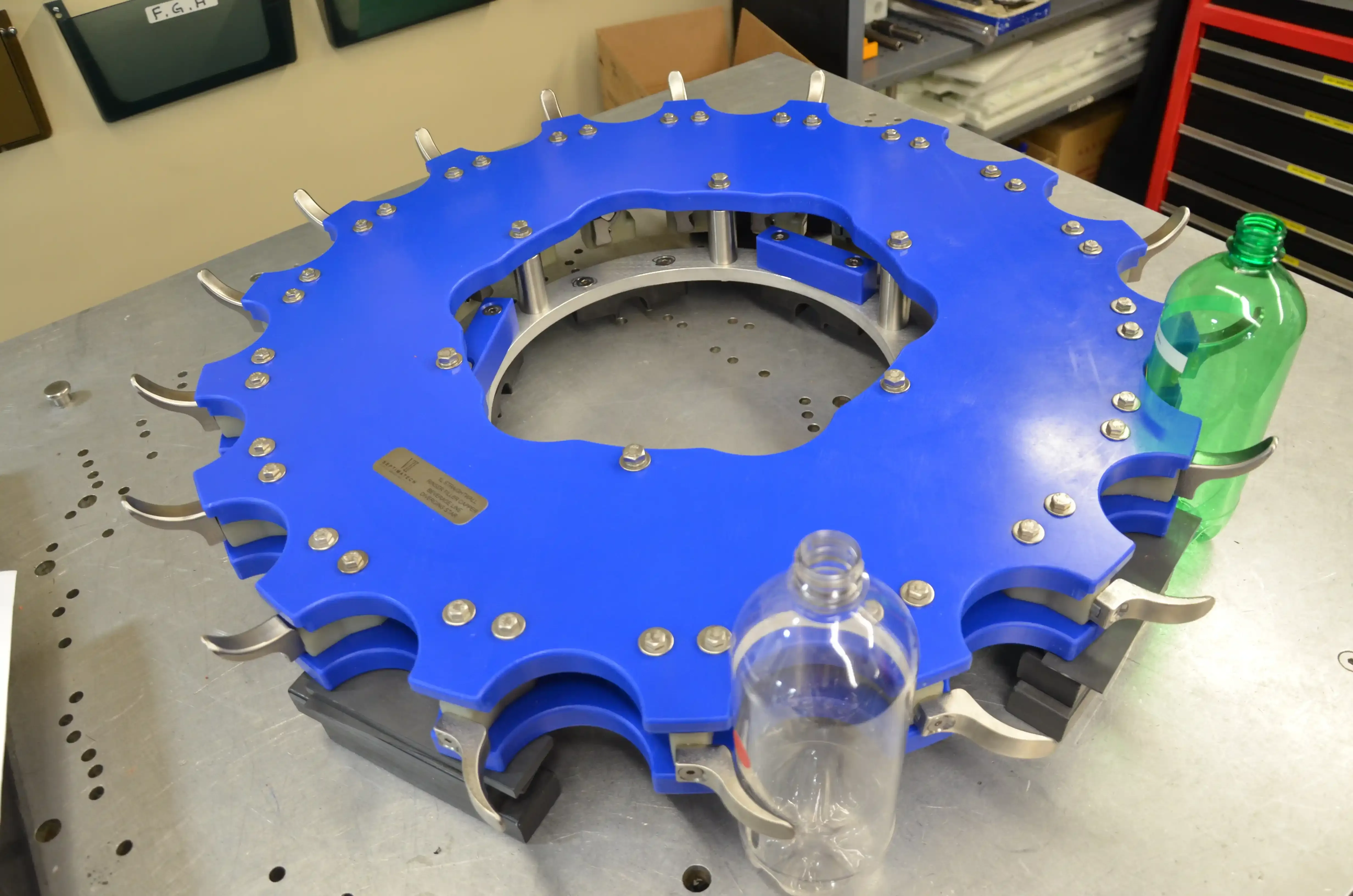

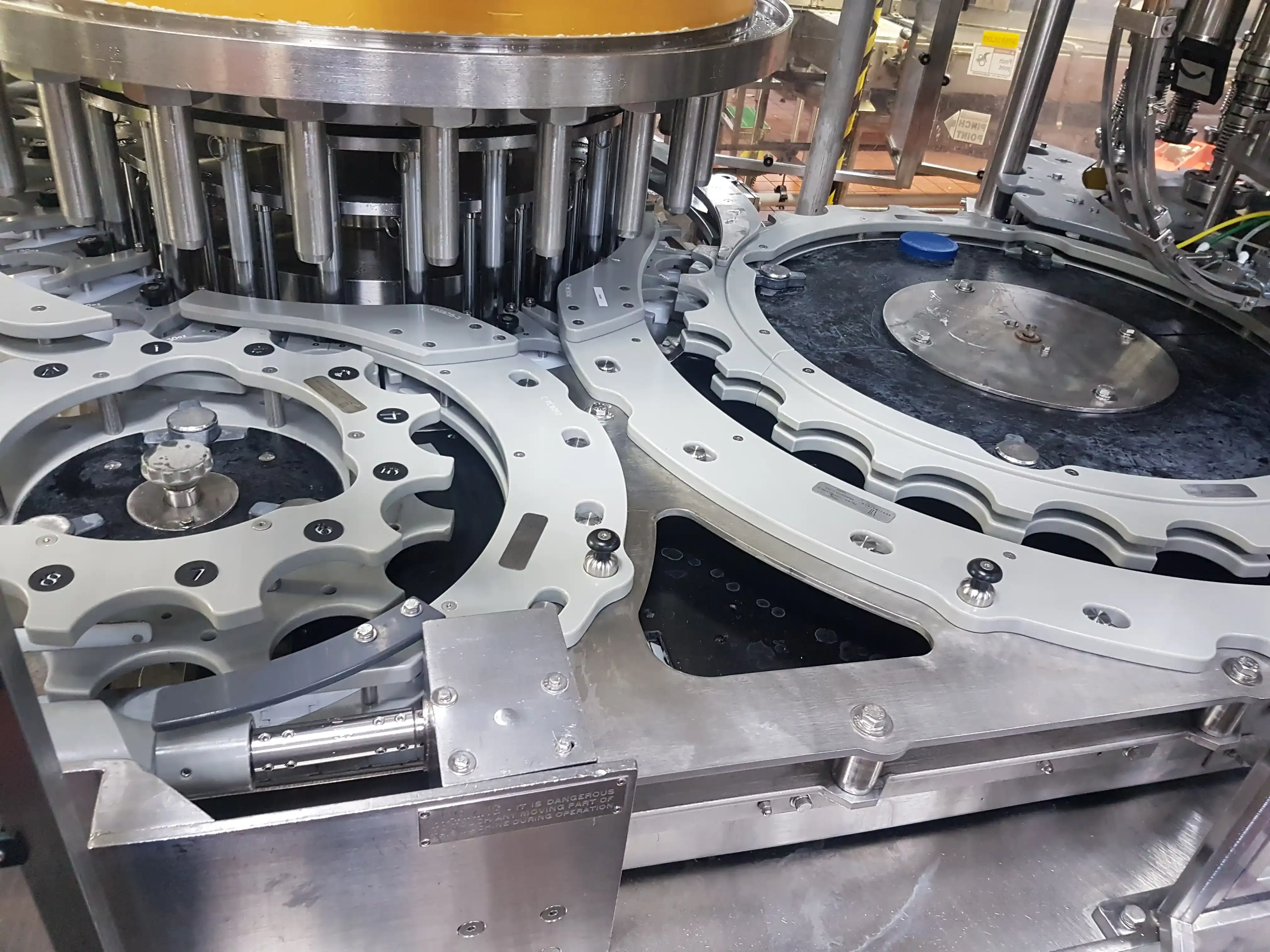

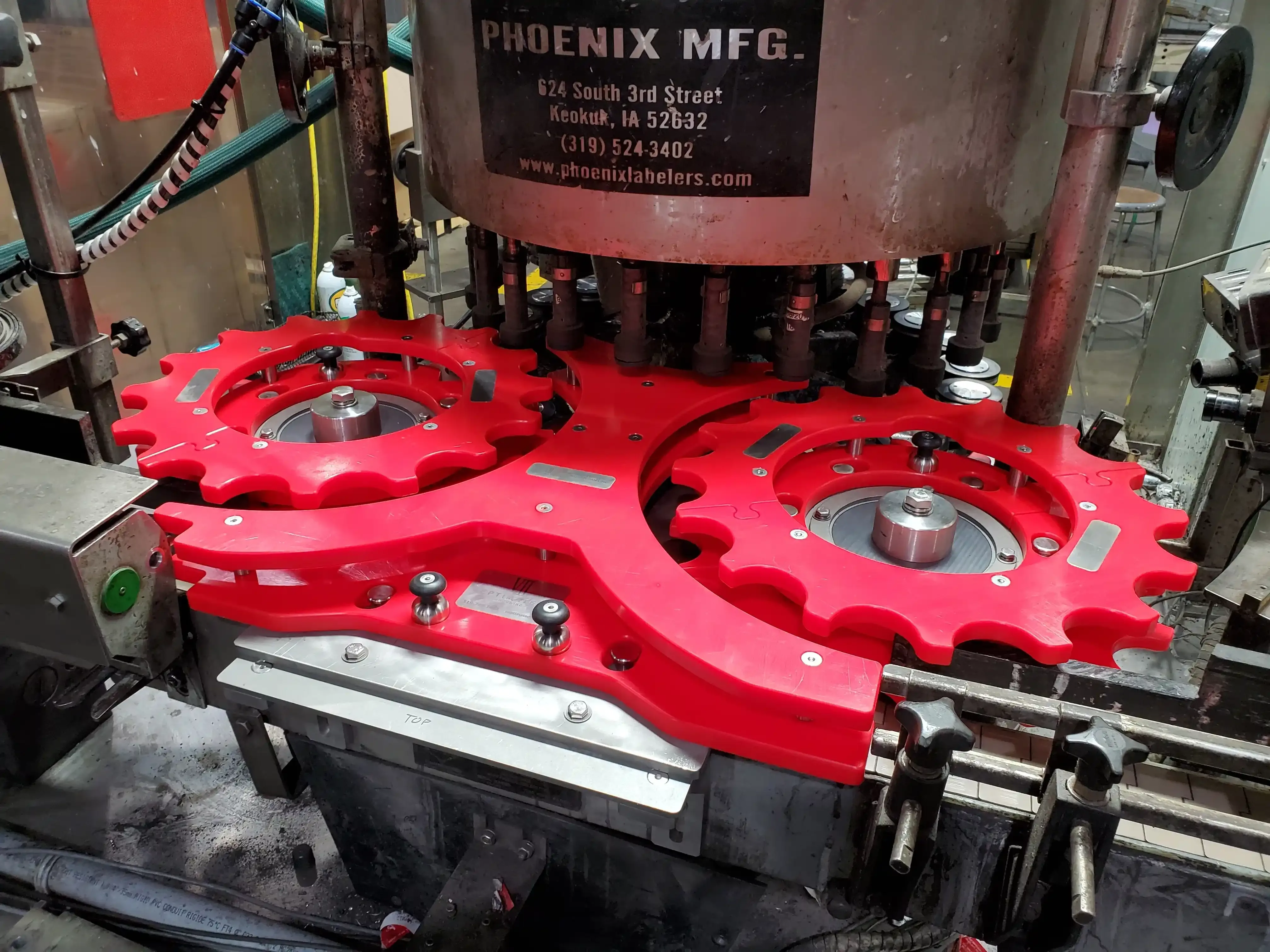

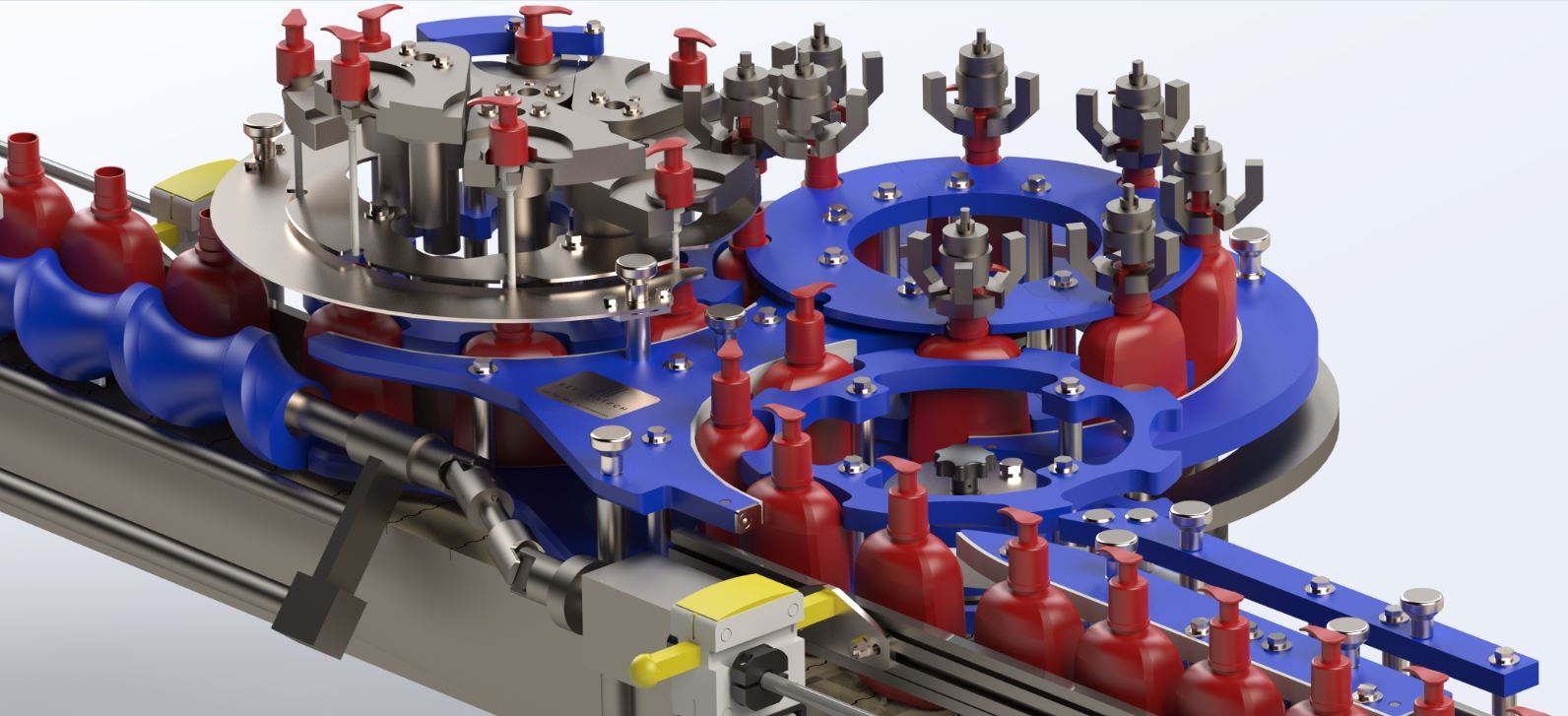

Change Parts

Star Wheels, Guides, Positioners, Bottle Plates, Centering Bells, other machine change parts.

Bottle handling Change Parts engineered for fast, accurate, and repeatable machine changeovers. Puzzle-cut parts and locating pins ensure precise positioning.

Septimatech’s change part solutions help customers achieve significant improvements in overall equipment effectiveness (OEE). Solutions supplied and installed on over 2,700 different machine makes and models.

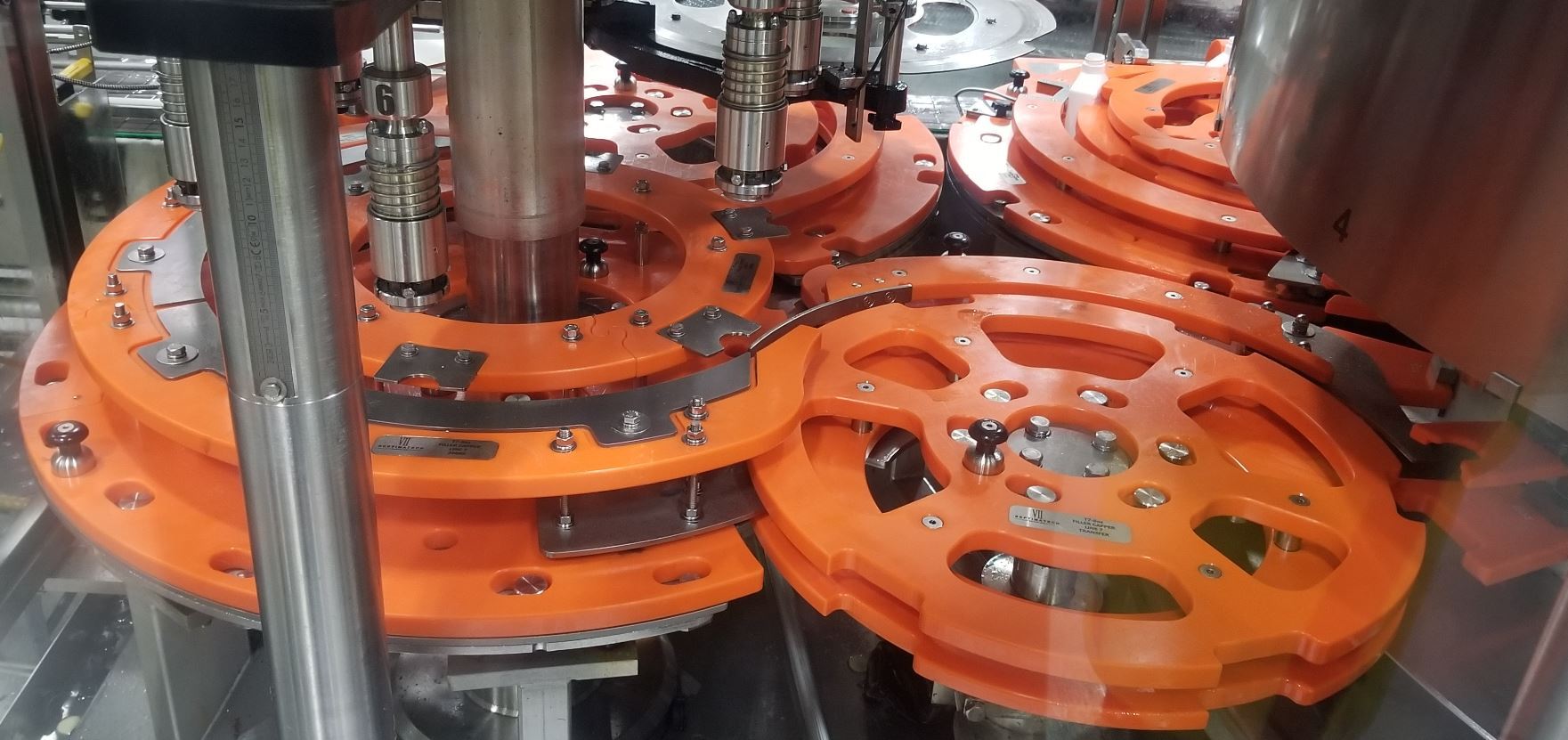

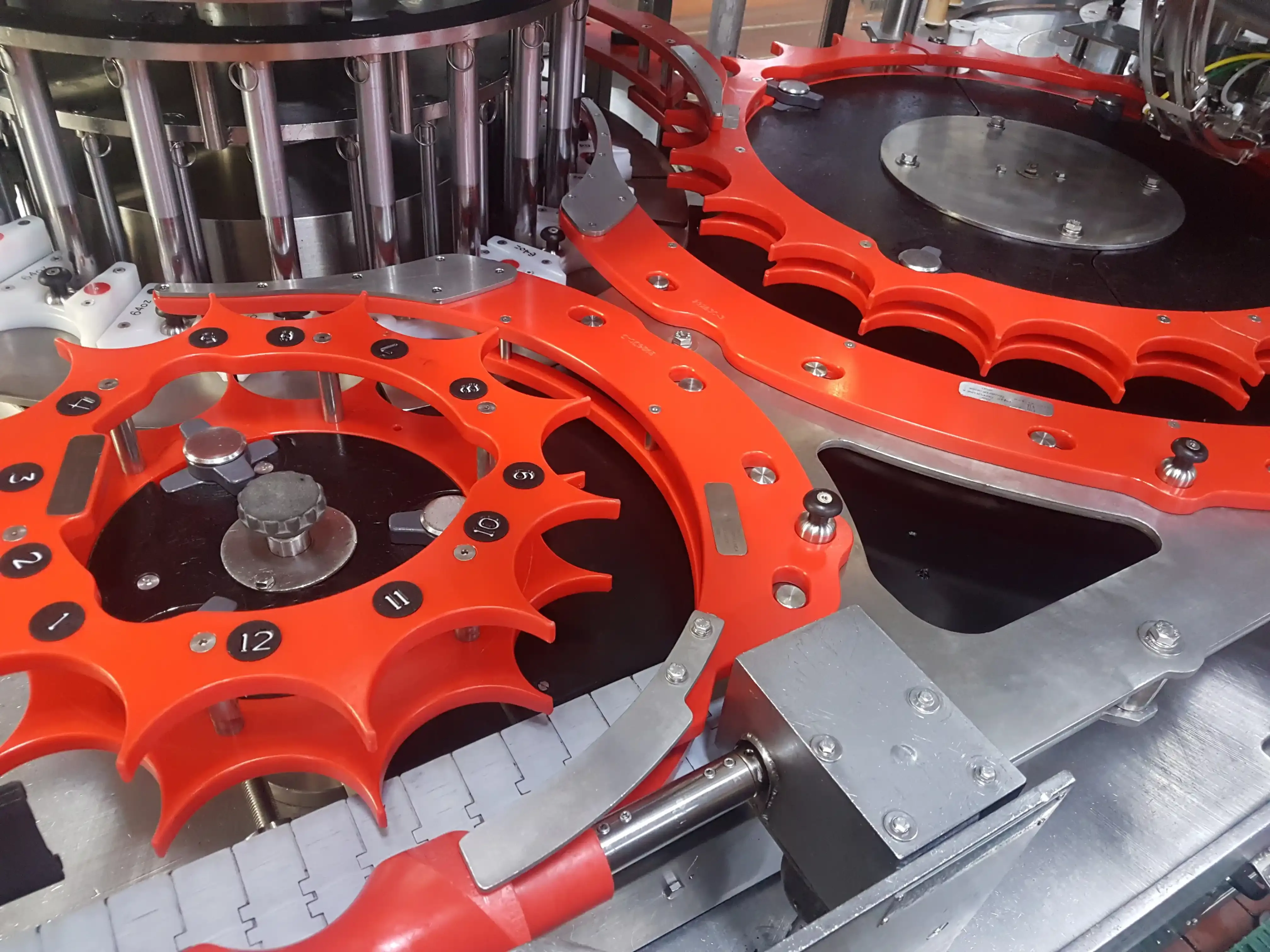

- Color-coding for proper change part identification and installation.

- Choice of 36 color combinations for SKUs and machine differentiation.

- Precision engineering and simulation of all bottle handling parts.

- Wash-down ready.

- Lightweight, durable materials for increased ergonomics and safety.

- Engineered materials selected to meet your production environment.

- Long-wear, abrasion resistant life.

- Custom engraving for easy identification.

- Enhanced container handling.

- Advanced digital measurement and 3-D CAD modelled change parts design.

- Quick lead times and attentive service.

- Custom-engineered to your machine’s current change part mounting references for maximum performance.

- Improved changeover allowing increased machine uptime.

- Proven results on more than 2,700 machine makes and models worldwide.

- Wide range of Industry experience solving container handling & bottle handling challenges.

Additional Change Part Solutions

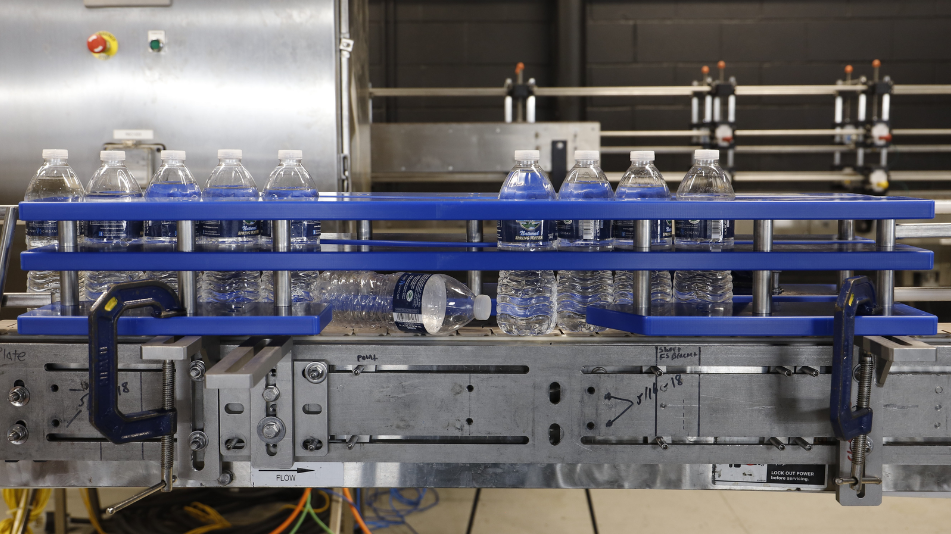

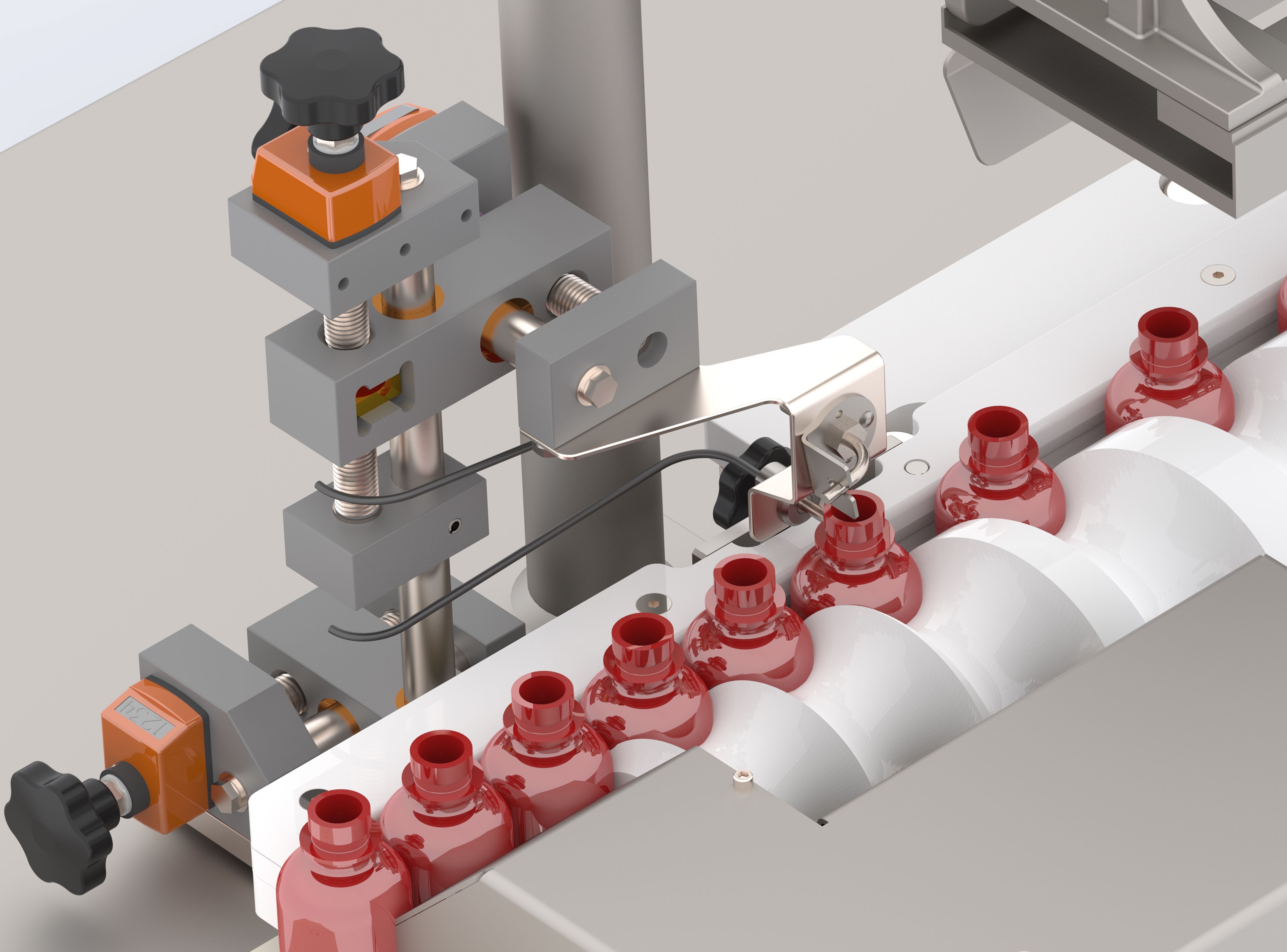

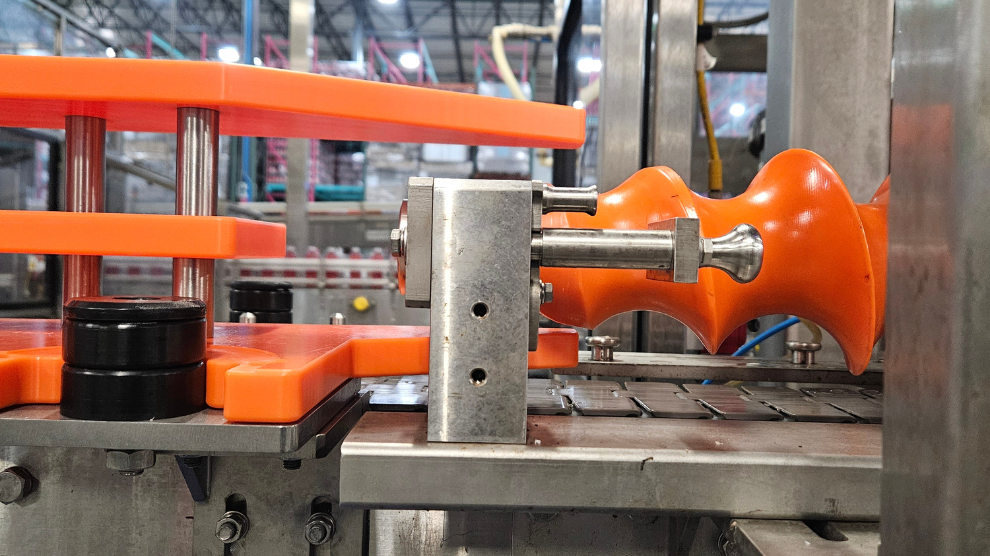

Automatically reject downed bottles that have fallen over or tipped during packaging processes using a Downed Bottle Reject system from Septimatech.

This quick change solution easily installs onto your conveyor, using the shape of containers to reject downed bottles, which eliminates crashes on your line. No moving parts or pneumatic systems ensures maintenance free, repeatable operation.

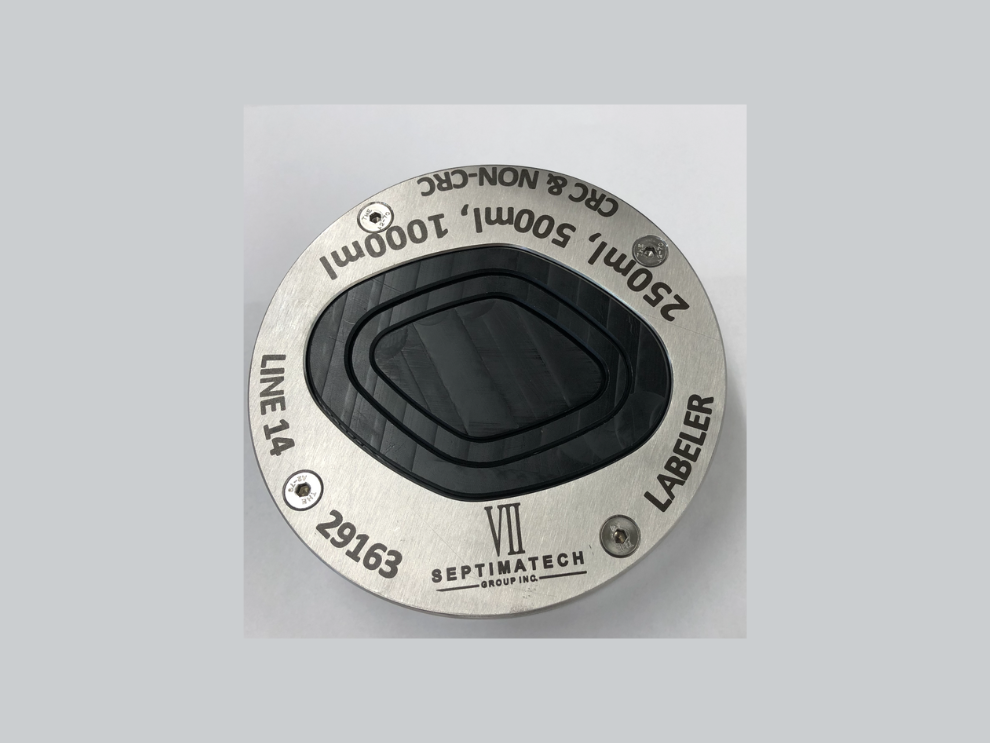

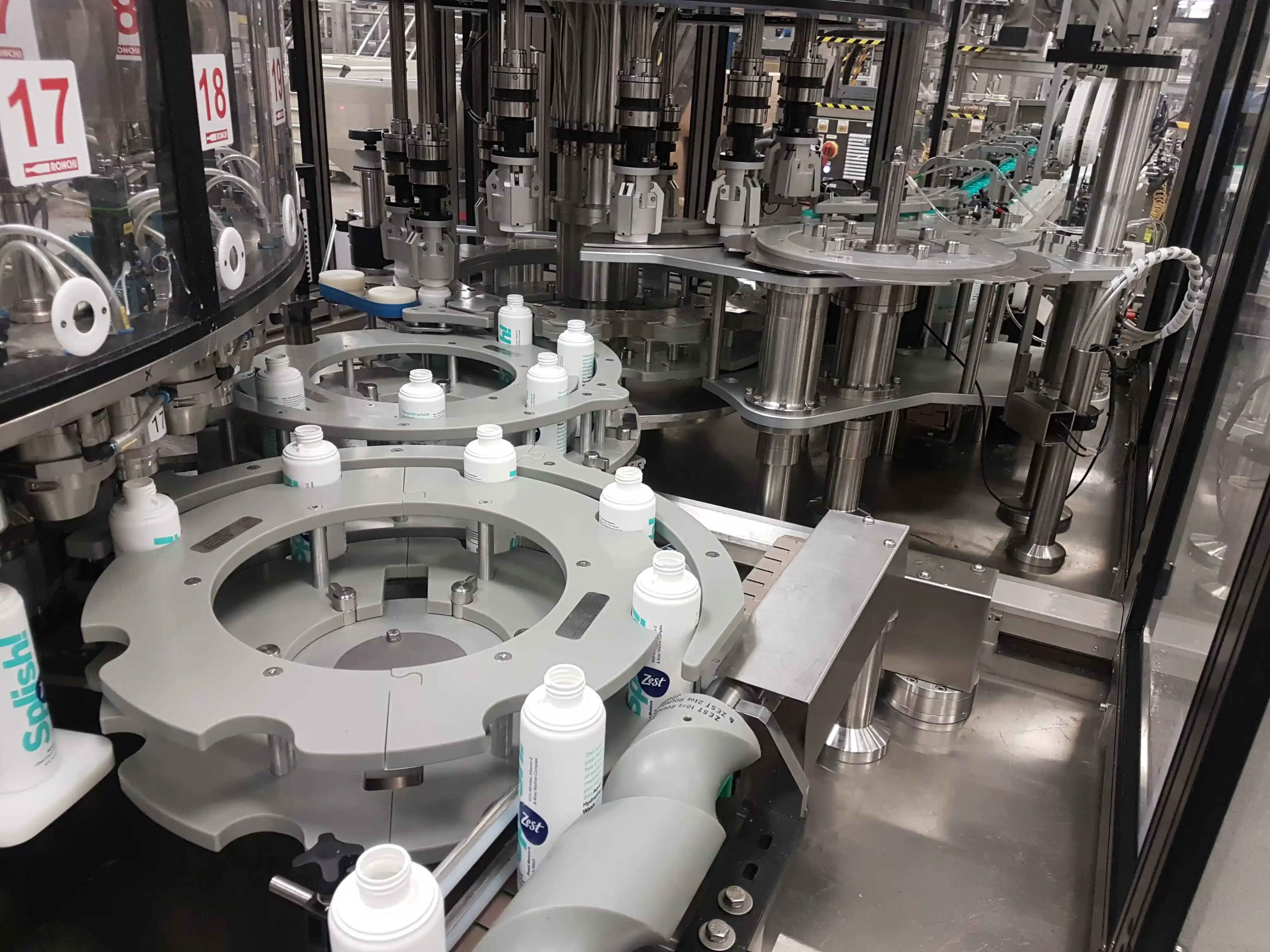

Septimatech's label handling change parts ensure precise, repeatable adjustments for accurate label application across various container shapes and sizes. These solutions maximize uptime and maintain labeling consistency while meeting OEM specifications and achieving shorter lead times.

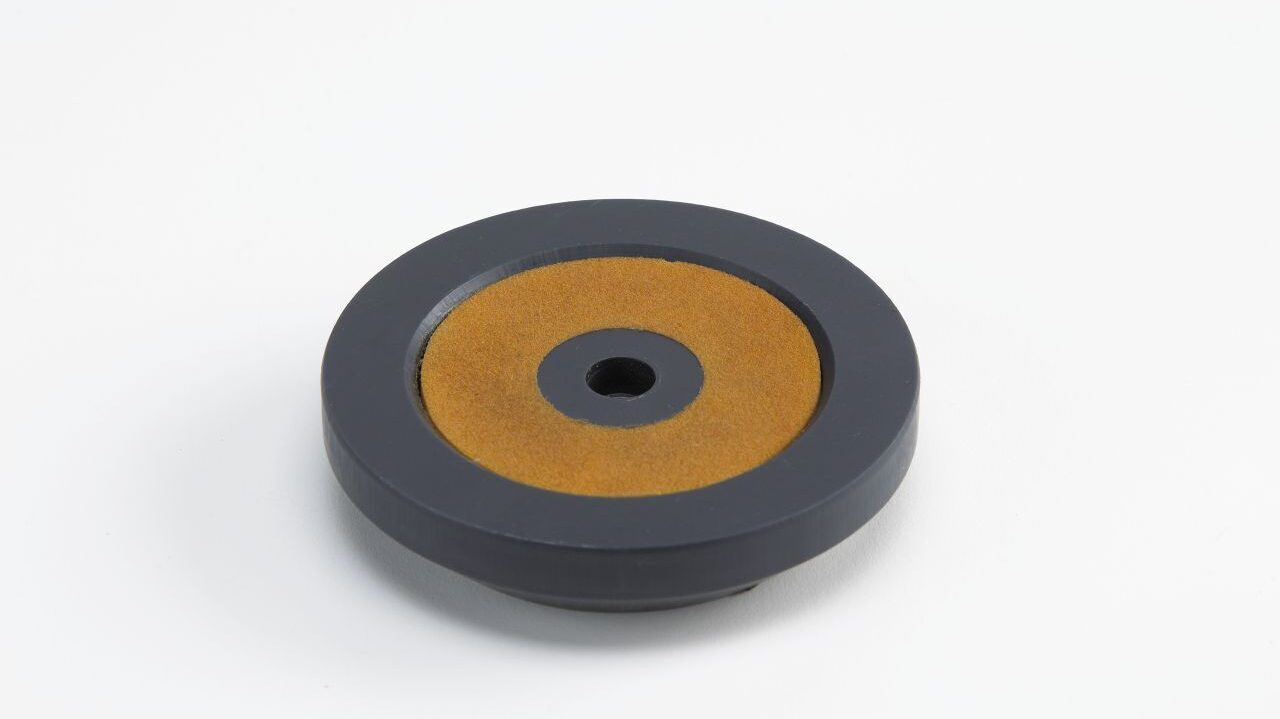

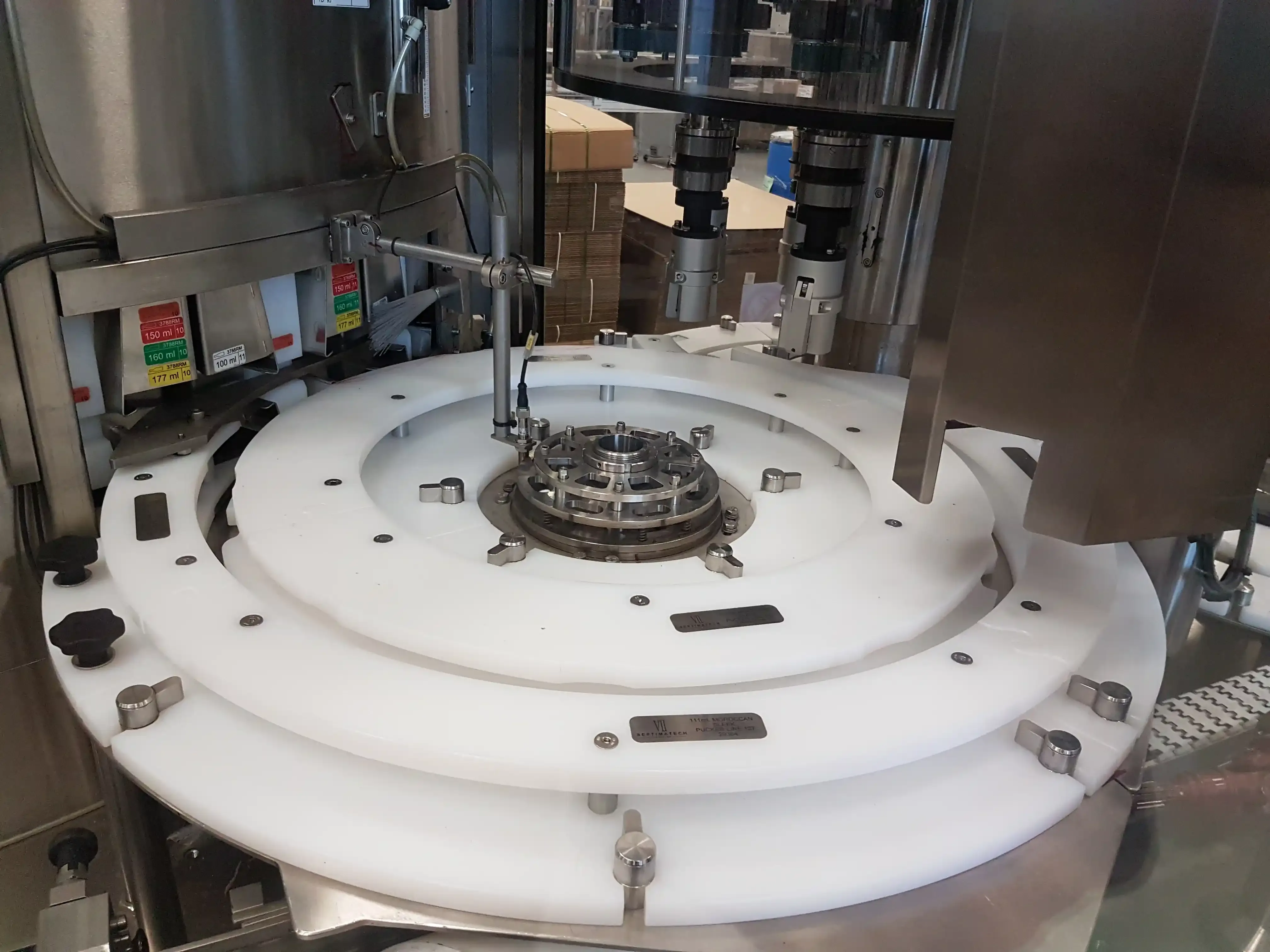

Septimatech offers a comprehensive range of centering bells for air cleaners, fillers, and labelers. Our engineered solutions are designed to fit various container shapes and sizes, for any make & model of machine. Customers achieved accurate positioning of containers and precise down pressure for consistent filling and labelling of containers.

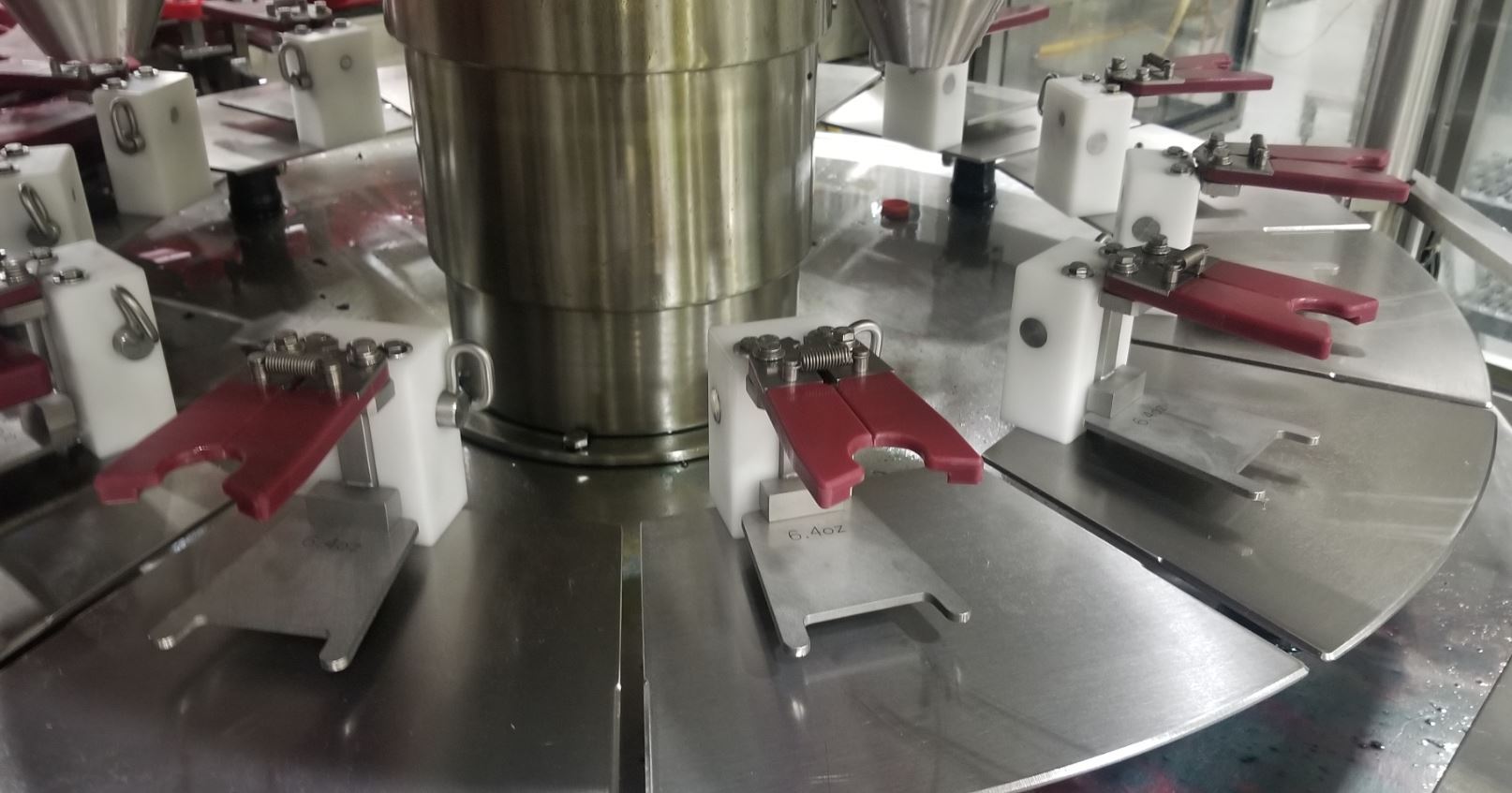

Septimatech provides specialized neck grippers for rinser's, washers, and filling machines designed to securely hold, stabilize, and position bottles during the cleaning and filling processes.

These grippers ensure precise positioning of various bottle shapes and sizes, reducing slippage, and increasing uptime.

Septimatech's experience supplying Neck Grippers for the high-speed beverage industry ensures reliable bottle control.

Septimatech’s positioner assemblies and body locators provide precise container alignment and stability throughout filling and capping operations on your packaging equipment, minimizing misalignment and enhancing container handling accuracy & placement.

Our greater than 3 decades experience helps us engineer quick change positioner assemblies and body locators for more accurate label placement, less spilled product, and less product agitation.

Septimatech engineers custom orienting/spotting change parts which ensure precise and consistent container orientation for labelling, filling, and other container orienting requirements.

Our custom solutions are essential for applications such as filling and labeling where accurate positioning is critical.

Ready for a Quote?

Boost your line efficiency—get an aftermarket change parts quote now!