Beverage Industry

Septimatech is one of the world’s leading providers of changeover and container handling solutions for the fast paced, constantly evolving beverage industry.

Simple, precise set-ups deliver enhanced container handling that eliminates shingling, scuffing, and marking—even for space constrained line configurations such as tight radius corners.

Septimatech’s changeover solutions reduce splashing and can be constructed for use in aspetic environments. Septimatech also designs and manufactures a wide range of custom solutions for unique applications like steam washdowns and flood filling.

Resources:

Food Industry

Septimatech is a pioneer in changeover and container handling solutions for food applications. We help our food customers with multiple SKUs simplify changeovers, enhance container control, and reduce downtime to maximize production and efficiency. Our experienced team members are experts in catering towards situations that are unique to the food industry, like hot filling applications and specific FDA requirements.

All Septimatech solutions can be manufactured using stainless steel and manufactured for aseptic environments. They are designed to reduce ergonomic risk and easy-to-use and maintain by one person.

Resources:

- Crashes due to Downed Bottles case study

- Create a Competitive Advantage by Improving Changeover Efficiency in food packaging

Original Equipment Manufacturers

If you are an OEM looking to increase aftermarket sales and revenue while reducing costs, we can help you focus on your core business of building great packaging machines. Septimatech has manufactured change parts and container control solutions for more than 2,700 different machine models on operating on hundreds of lines worldwide.

For more than 30 years we have applied our expertise in lean manufacturing, changeovers and container handling to create superior, high value change parts.

We offer our OEM partners a wide range of standard and custom changeover and container handling solutions, and use a part numbering system. We provide short lead times and have manufactured solutions for nearly every shape and size of container available today. We support you on your changeover needs so your can focus on the machine itself.

Septimatech change parts, feed screws, feed screw drives, adjustable guide rails, and change part storage carts are easy-to-use, maintain and washdown. All our changeover solutions are precise, repeatable, and designed for fast, accurate changeovers by one person.

We work closely with our OEM partners to help them deliver superior changeover and container handling solutions quickly.

Pharmaceutical & Nutraceutical Industry

Septimatech solutions provide a competitive advantage for manufacturers in the fast-paced, constantly changing pharmaceutical and nutraceutical industries catering to the unique needs of specific FDA requirements, and clean rooms standards.

Our experienced team members are experts in overcoming container handling challenges in cleanroom and highly regulated production environments to ensure maximum product protection and eliminate product loss.

Our best-in-class change parts and adjustable guide rail solutions can be designed to prevent product pooling and manufactured to ensure fasterners are hidden and any surfaces are finished to standard (eg. electro polishing, conical surfaces, 316L passivation).

Resources:

- Change Parts Storage Solutions Designed for Versatility in Pharmaceutical Changeovers

- Three Key Ways Pharmaceutical Manufacturers Gain an Edge by Collaborating with Changeover and Container Handling Specialists

- Pharmaceutical Storage Solutions case study

- Limited Inline filler capabilities pharmaceutical case study

Automotive & Lubricants Industry

Septimatech solutions provide a competitive advantage for manufacturers of automotive fluids, solvents, lubricants and other petroleum-based products. Septimatech changeover and container handling solutions are ideal for manufacturers looking to overcome production challenges caused by frequent changeovers and running multiple container types.

Septimatech changeover solutions provide fast, accurate, repeatable changeovers and smooth container handling for containers of nearly any shape or size, manufactured with anti-static dissipating materials without causing any scuffing, marking or additional friction that may cause explosions or fires.

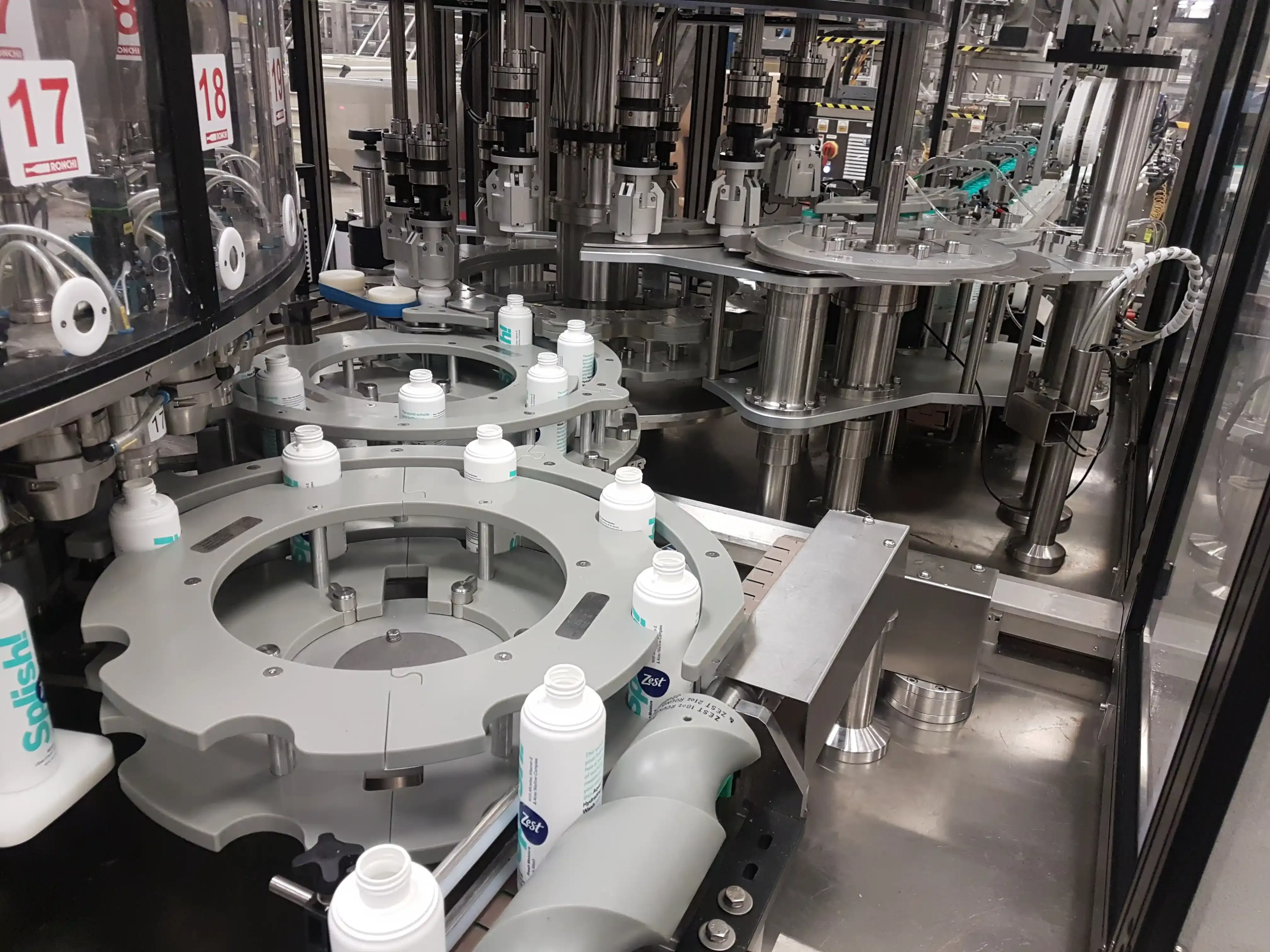

Personal Care Industry

Septimatech is one of the world’s leading providers of changeover and container handling solutions for the Personal Care industry. Our best-in-class change parts and adjustable guide rail solutions maximize changeover efficiency and container handling performance for lines running bottles, containers, and caps that have a complex geometry.

Septimatech changeover solutions provide fast, accurate, repeatable changeovers and smooth container handling without scuffing and marking. Our adjustable line and guide rail solutions provide fast, repeatable changeovers and reduce shingling and jams, even for tight space line configurations. Septimatech’s solutions can all be manufactured to ensure that there are no collection areas for bacteria.

Resources:

- Automated Packaging Solutions: Eliminating Manual Operations with Septimatech

- Container Orientation case study for personal care line

- Cap Positioning Challenges case study

Contract Packagers

Septimatech changeover and container handling solutions provide copackers with increased line and machine flexibility so they can run a wide range of container types, including obscure and difficult container sizes and shapes. We have manufactured solutions for more than 2,700 different machine models operating on hundreds of lines worldwide.

Our solutions help co-packers maximize production and speed to market for their customers, while reducing many of the risks associated with contract packaging. We offer a wide range of standard and custom changeover and container handling solutions that deliver fast, simple multi-container changeovers and efficient, ergonomic storage.

Septimatech has built up an extensive catalogue of changeover parts for many bottle/container types over the years, meaning if you have a container, you think you may need a new part for, we may have already designed a solution for it. All our changeover solutions are precise, repeatable, and designed for fast, accurate changeovers by one person.

Chemical & Cleaning Industry

Septimatech is one of the world’s leading providers of changeover and container handling solutions for household and industrial chemical and cleaning products. Our industry experience has allowed us to anticipate the effects that specific chemicals have on materials and as such we offer a wide range of materials to avoid corrosion, like titanium or specific plastics.

All Septimatech changeover and container handling solutions are washdown capable and inert to caustic cleaning solutions. Septimatech solutions also reduce ergonomic risk and are easy to install, set-up and maintain by one person.

Pet Care Industry

Septimatech changeover and container handling solutions are ideal for pet care and food manufacturers looking to overcome production challenges caused by frequent changeovers, smaller batches and multiple SKUs. All products can be manufactured for FDA compliance if required. Hygienic designs and stainless-steel materials make cleaning easy and reduce part wear.

Simple, precise set-ups deliver enhanced container handling that eliminates shingling, scuffing, and marking—even for space constrained line configurations such as tight radius corners. Septimatech Feed Screw Drives and Feed Screws ensure precise timing, container flow, and product orientation for maximum speed and efficiency.