Customer Challenge:

The Customer is experiencing excessive down time and maintenance costs as a result of crashes on their filling machine due to fallen containers entering the machine at speeds of 275 CPM. The family of 3 containers they are packaging, are unstable as the container is tall and slender with a small container base.

About the Customer

The Customer is a large multi-national manufacturer of consumer beverage and food products which has been unsuccessful at finding a solution which wouldn’t require them to purchase a new piece of equipment. They were looking for a solution which would be minimal maintenance and quick change over between package sizes, without substantial capital expense.

Solution

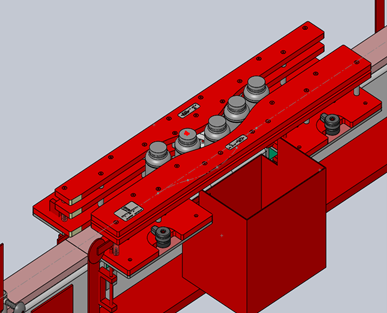

Septimatech engineered a mechanical/gravity system which would allow upright containers to transfer thru efficiently and fallen containers would be diverted to a recycling bin at 275 CPM. The system was able to be changed within minutes to a different bottle size, requiring no set up for production.

Customer Results

The Customer eliminated line stoppage resulting from filler stoppage with fallen containers, resulting in increased line operating efficiency. As well, they realized shortened production ramp up time with no tools or set up required by line operators for completing a change over.