Customer Challenge:

A Customer was required to run a very large container on a machine which is too small to fit the container. The pitch diameter of the stars is too small to accommodate this very large container. Adding to the challenge, the bottles were very rectangular in shape and due to their size, a Feed Screw could not be used to separate the bottles.

About the Customer

The Customer is a well-known medium sized manufacturer of industrial cleaning products. They package a wide variety of containers in an array of shapes and sizes and were unable to transfer this production to another machine in their plant.

Solution

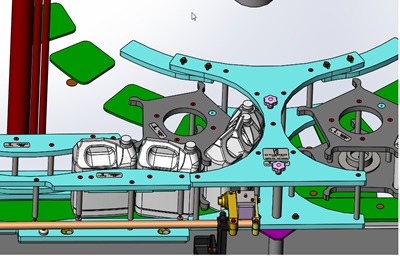

Septimatech developed a Wavy Guide Infeed System to generate the required container separation, for repeatable feeding into the infeed star. The infeed star and guide pitch diameters were modified, to create a star wheel pocket to feed the container onto the filler by an oversized pitch diameter, with an unique guide extension being added to the machine, to align the containers back onto the machines nominal filler pitch for filling. The same solution was repeated for the discharge star and guide assembly.

Customer Results

Our Customer was able to utilize their existing machine to package this container, eliminating the concern of transferring the production to another packaging plant or out-sourcing the business to a co-packer.