Customer Challenge:

Customer needed to store multiple complex geometry and fragile change parts which are prone to marking, or damage, if not handled delicately. They have limited storage space and the parts need to be stored so they remain dust and contaminant free after being cleaned. The current storage process utilized, results in damaged parts, excessive preparation for the autoclave process, and improper inventory of change parts, prior to beginning the changeover process.

About the Customer

The Customer is a large multi-national contract packager for pharmaceutical products. The industry regulations, which pertain to the hospital grade product the change parts handle, required the Customer to develop a unique solution which other OEM’s and solution providers were unable to provide.

Solution

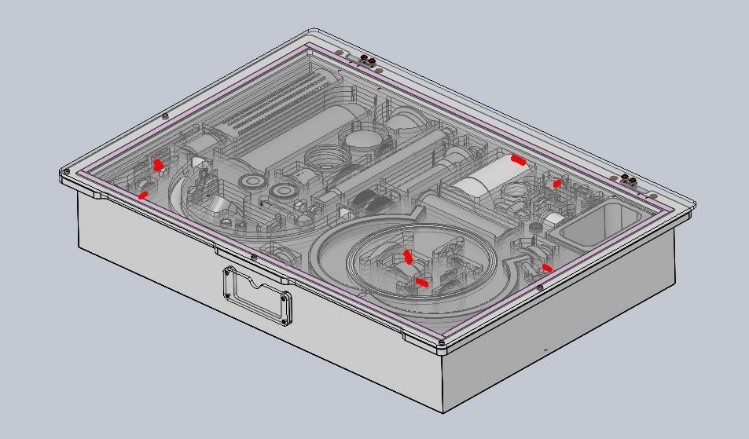

Septimatech, in collaboration with the Customer, developed a solution which comprised of a specialty foam insert with precision cut profiles to match the geometry of each Change Part. This allowed separate cavities to securely store each Change Part. The foam insert is in a sealed enclosure, with a magnetic catch that retains a clear see thru lid in a closed position, creating the required seal to prevent contamination of the clean Change Parts.

Customer Results

The Customer instantly realized efficiency gains in their changeover process, with accurate inventory of parts prior to starting a changeover, reduction in preparation time for autoclave process and eliminated costs associated to damaged change parts.