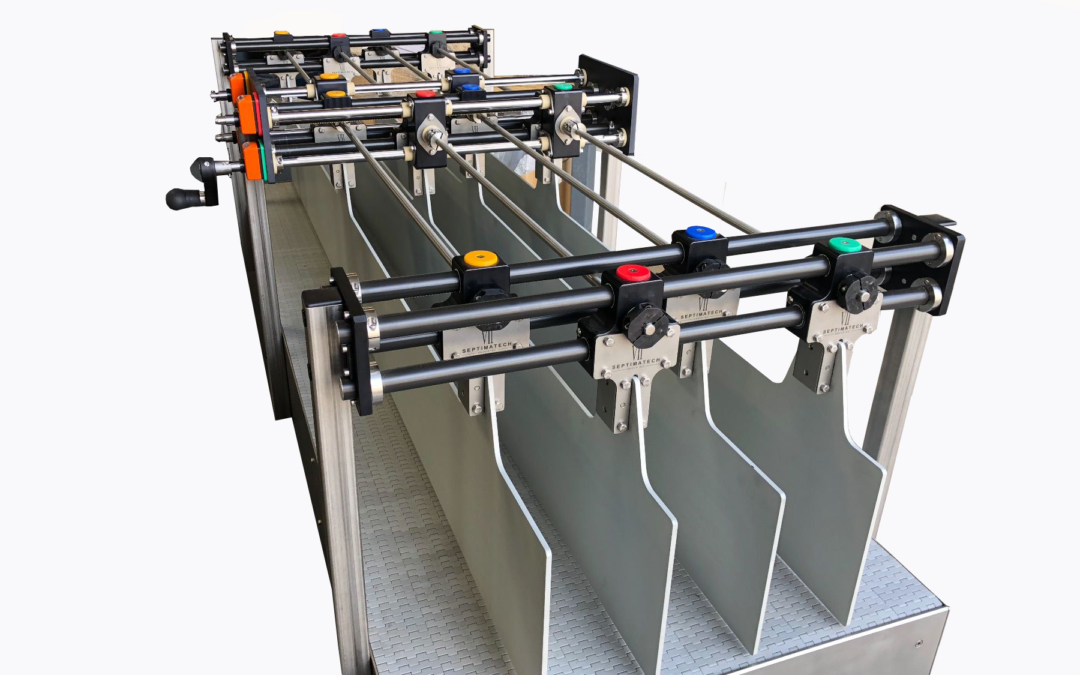

Multi-Lane Guide Rail Adjustment

The New Multi-Lane Guide Rail Adjustment System for adjusting multiple conveyor lane guides without changing parts, using lane spacers, or heavy lifting equipment. The elimination of change parts, lane spacers and heavy lifting equipment frees up valuable plant space and operator time for other production needs.

With Septimatech’s Multi-Lane Guide Rail Adjustment System, one person can simultaneously adjust a 30 foot (9 m) section of Case Packer accumulation lane dividers and lane guides from one location. Typically, a similar section of Case Packer divider rails and lane guides would take two people 35-50 minutes to adjust to the proper settings. The Multi-Lane Guide Rail Adjustment System allows one person to adjust a similar section of Case Packer divider rails and lane guides in less than 5 minutes without tools.

The Multi-Lane Conveyor Guide Rail Adjustment System is suitable for a wide variety of packaging applications where adjustable Case Packer rails or lane dividers are required. Adjustment of accumulation lanes, lane dividers, lane guides and guide rails are accurate and repeatable with precise tolerances to improve container handling from start to finish. Container funneling can be adjusted from a maximum of four lanes to one. Minor conveyor adjustments during production runs for container variances are quick, simple and accurate. Intuitive wheel operation and settings readout is simple to use and learn.

Benefits:

- Adapts easily to existing or new equipment

- Increase accuracy and repeat-ability

- No lifting equipment required – ergonomics and safety are improved

- One person to change entire system

- Set up without templates or spacers

- Storage space no longer needed for multiple template storage

- Quick return on investment resulting from reduced labor, increased efficiency, improved throughput

- Adjustable lane dividers, guide rails or side guides on Case packers, Accumulation Conveyor & Multi Lane Conveyor